Method for purifying sugammadex sodium

A sugammadex sodium and purification method technology, which is applied in the field of purifying sugammadex sodium with pretreated Bailu Z activated carbon, can solve the problems of not being able to obtain high-purity sugammadex sodium products, and achieve good industrialization Prospect, high purity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

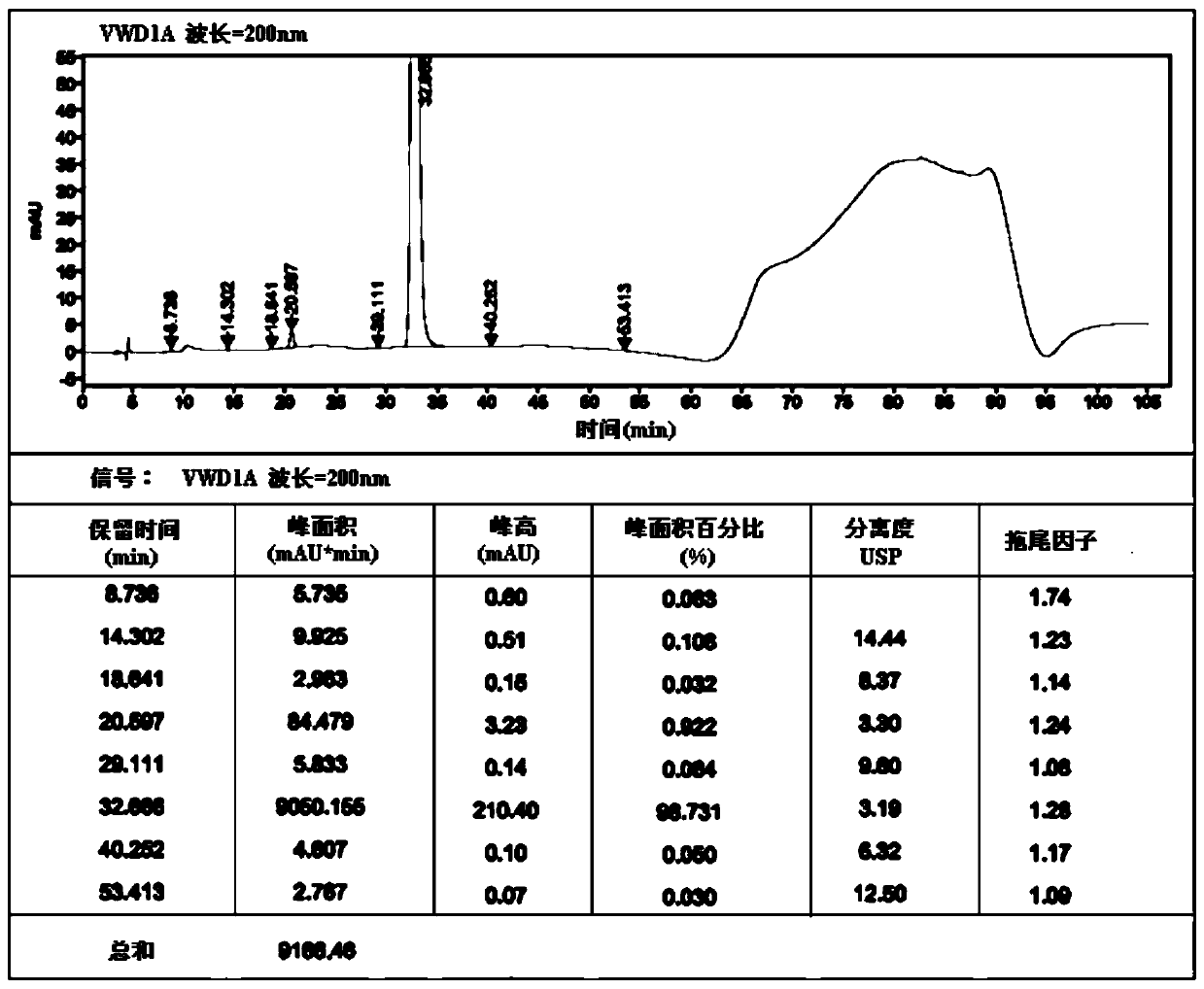

[0040] Example 1

[0041] A purification method of sugammadex sodium of the present invention, comprising the following steps:

[0042] (1) Take 5 g of Egret Z (CARBORAFIN) activated carbon, add it to a three-necked flask, add 100 mL of purified water to the three-necked flask, insert a nitrogen tube under the liquid surface, and continuously fill nitrogen at room temperature (20°C to 30°C) and stir for half an hour , and then suction filtered under the protection of nitrogen to obtain pretreated Egret Z (CARBORAFIN) activated carbon, which was filled with nitrogen and sealed for storage.

[0043] (2) Add 20 g of sugammadex sodium crude product into a 250 mL flask, add 80 mL of purified water to dissolve, add 4 g of the pretreated Egret Z (CARBORAFIN) activated carbon obtained in step (1), under nitrogen protection, room temperature (20 ° C ~ 30 ℃), stirred and adsorbed for 1 hour, filtered to remove gac, and the filtrate was added dropwise with 720mL of methanol to crystalli...

Example Embodiment

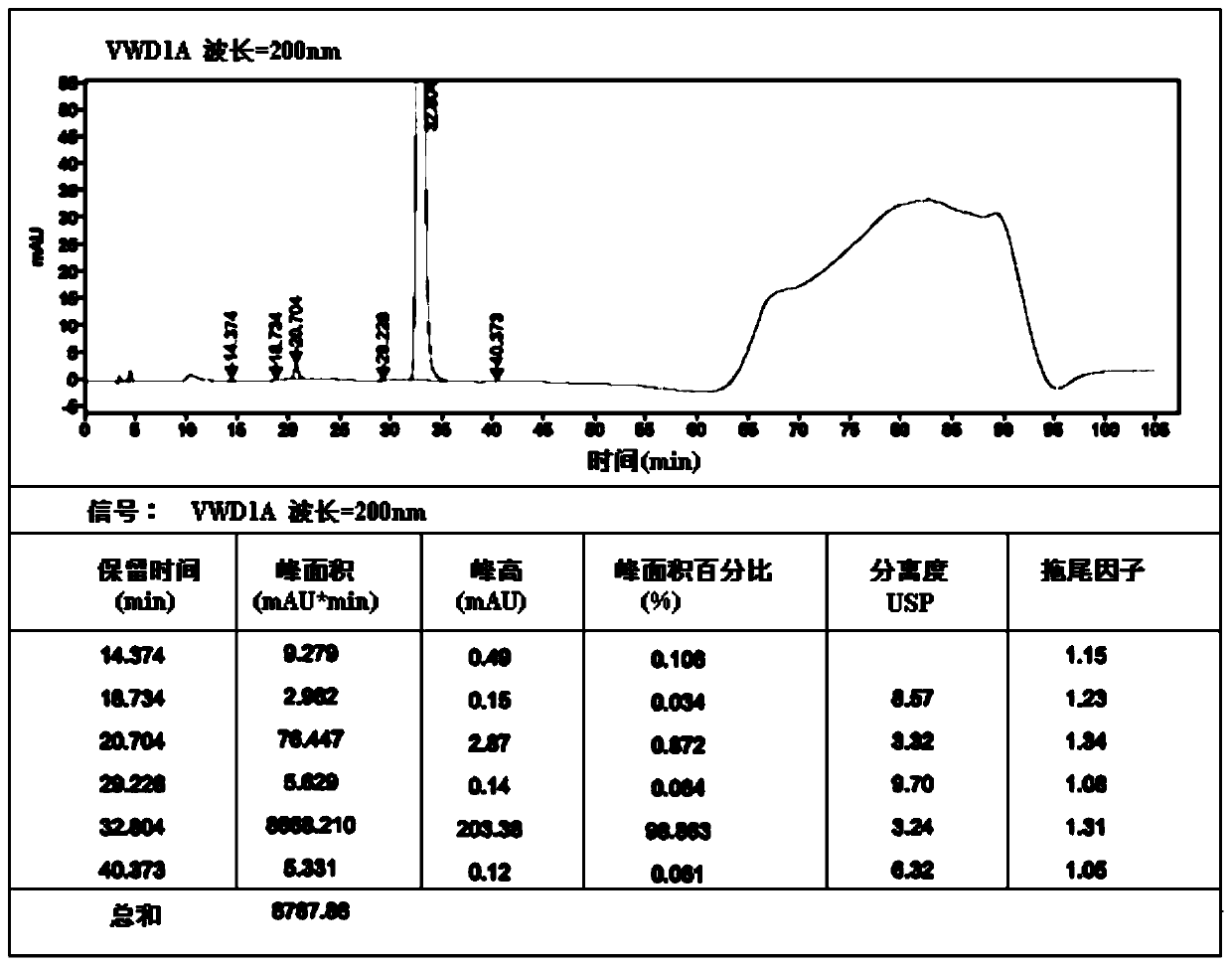

[0044] Example 2

[0045] A purification method of sugammadex sodium of the present invention, comprising the following steps:

[0046] (1) Take 5g of Egret Z (CARBORAFIN) activated carbon, add it to a three-necked flask, add 100mL of water to the flask, vacuumize for nitrogen replacement, and add 0.5g of sodium thiosulfate under nitrogen protection at room temperature (20°C~30°C) , stirred for half an hour, suction filtered under nitrogen protection, washed the filter cake with 50 milliliters of nitrogen-saturated purified water, and drained to obtain pretreated Egret Z (CARBORAFIN) activated carbon, which was filled with nitrogen and sealed for preservation.

[0047] (2) Add 20 g of sugammadex sodium crude product into a 250 mL flask, add 80 mL of purified water to dissolve, add 4 g of the pretreated Egret Z (CARBORAFIN) activated carbon obtained in step (1), and stir at 20 ° C to 30 ° C under nitrogen protection Adsorb for 1 hour, filter to remove activated carbon, add 400...

Example Embodiment

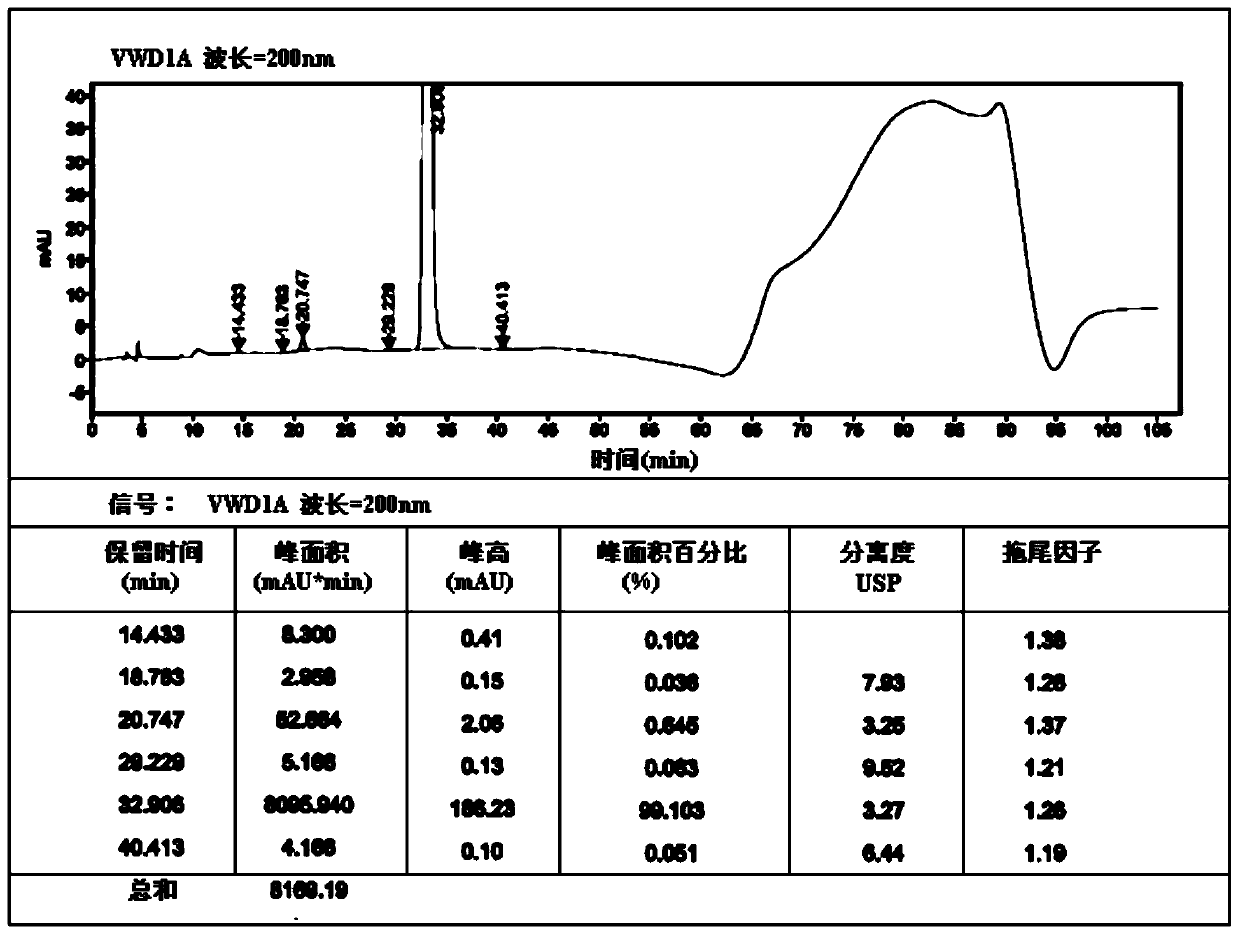

[0048] Example 3

[0049] A purification method of sugammadex sodium of the present invention, comprising the following steps:

[0050] (1) Take 5 g of Egret Z (CARBORAFIN) activated carbon, add it to a three-necked flask, add 100 mL of water into the flask, vacuumize for nitrogen replacement three times, heat up to 80°C to 85°C under the protection of nitrogen, keep stirring for half an hour, and then Cool to room temperature, suction filter under nitrogen protection, and drain to obtain pretreated Egret Z (CARBORAFIN) activated carbon, which is sealed and stored with nitrogen.

[0051] (2) Add 20 g of sugammadex sodium crude product into a 250 mL flask, add 80 mL of purified water to dissolve, add 4 g of the pretreated Egret Z (CARBORAFIN) activated carbon obtained in step (1), under nitrogen protection, room temperature (20 ° C ~ 30 ℃) stirred and adsorbed for 1 hour, filtered to remove activated carbon, added dropwise 400mL N,N-dimethylformamide to the filtrate to crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com