Comprehonsive utilization method of asbestos tail ore

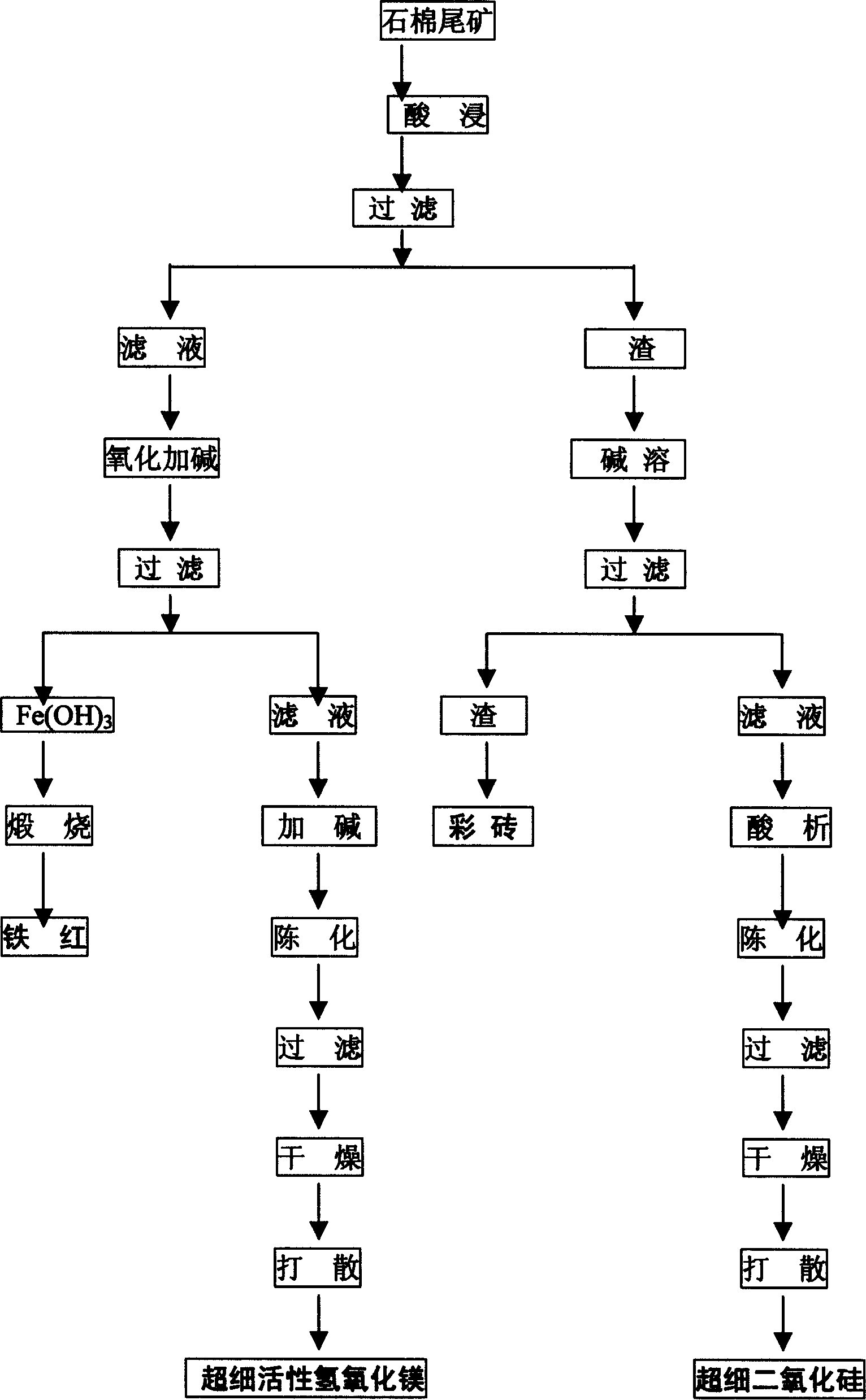

A kind of asbestos tailings and suitable technology, applied in the field of comprehensive utilization of asbestos tailings, can solve the problems of low comprehensive utilization rate and product grade, single extraction or utilization, etc., and achieve low comprehensive production cost, high comprehensive utilization rate and good product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] ① Take 100g of asbestos tailings powder and add 290g of 40% H 2 SO 4 , dissolved at 95°C for 1.5h; the solid residue was removed by filtration, and 3.6g of 30% H 2 o 2 , oxidize at 65°C for 45 minutes, adjust the pH value to 6, and sink for 45 minutes; filter and separate the iron hydroxide precipitate, adjust the Baume degree of the filtrate to 20°, add alkali to the pH value of 13 within 15 minutes, and the temperature is 95°C, add surface Treating agent (titanate YB301) 0.6%, stirring and aging for 40 minutes, filtering, washing and drying to obtain superfine magnesium hydroxide product.

[0042] Dry the iron hydroxide and calcinate it at 550°C for 0.5h in a laboratory muffle furnace to obtain the iron oxide product.

[0043] Add 22g NaOH to the acid-soluble solid residue, add 200mL water at the same time, dissolve at 95°C for 2h, filter to remove the residue, adjust the Baume degree of the filtrate to 18°, and add 4g NaOH 2 SO 4 , the temperature is 45°C, adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com