Method for preparing catalyst for catalyzing organic pollutants in wet oxidation water

A technology that catalyzes wet oxidation and organic pollutants. It is applied in the direction of catalyst activation/preparation, water pollutants, oxidized water/sewage treatment, etc. It can solve the problems of non-polar solvents that are not environmentally friendly, and achieve good hydrothermal stability and stability. Good performance and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

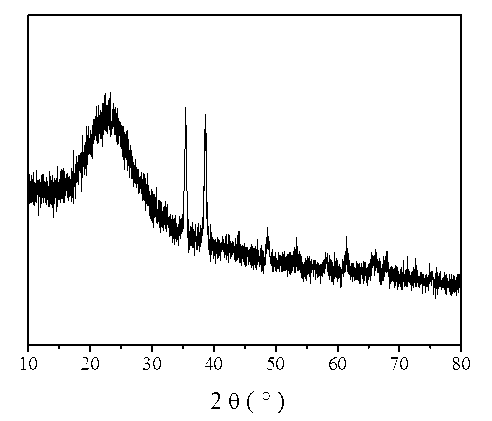

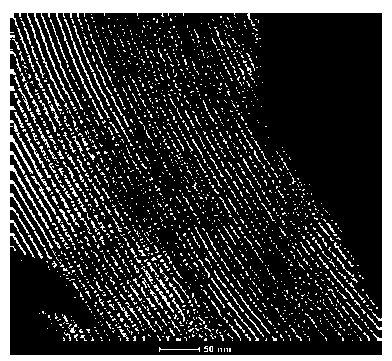

Image

Examples

preparation example Construction

[0030] 1. Preparation of SBA-15 mesoporous molecular sieve:

[0031] (1) Take 1.6ml of concentrated hydrochloric acid in 130.0ml of water to make a hydrochloric acid aqueous solution with pH ≈ 1.0.

[0032] (2) Take 100.0ml of aqueous hydrochloric acid solution prepared in step (1), and weigh 4.0g of template agent triblock copolymer EO 20 PO 70 EO 20 (P123) was stirred in a 40.0°C water bath to fully dissolve it to form a mixed aqueous solution containing P123.

[0033] (3) Weigh 9.0g of tetraethyl orthosilicate (TEOS) and place it in the remaining hydrochloric acid aqueous solution (about 31.6ml) in step (1), and pre-hydrolyze TEOS in a water bath at 40.0°C for 3.0h to form orthosilicon-containing Mixed aqueous solution of ethyl acetate (TEOS).

[0034] (4) Add the mixed aqueous solution containing TEOS to the P123 mixed aqueous solution dropwise, and stir in a water bath at 40.0°C for 24.0h; Crystallization 48.0h.

[0035] (5) After the crystallization, the obtained c...

example 1

[0049] The prepared CuO-Fe 2 o 3 / SBA-15 catalyst for catalytic oxidation treatment of organic wastewater containing phenol.

[0050] The initial concentration of organic wastewater is 200mg·L -1 phenol aqueous solution, the amount of catalyst is 0.3g / L, the initial concentration of hydrogen peroxide is 1.5g / L, the treatment temperature is 60°C, and the operation is under normal pressure. After 60 minutes of treatment, the removal rate of phenol can reach 100%, and the removal rate of TOC Up to 86.0%.

example 2

[0052] The prepared CuO-Fe 2 o 3 / SBA-15 catalyst for catalytic oxidation of rhodamine B in aqueous solution.

[0053] The initial concentration of Rhodamine B was 100mg·L -1 , the amount of catalyst is 0.4g / L, the initial concentration of hydrogen peroxide is 1.8g / L, the treatment temperature is 70°C, the operation is normal pressure, pH=7.0, after 100 minutes of treatment, the decolorization rate of rhodamine B can reach 100%. The removal rate of TOC can reach 67.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com