Comprehensive plating promoter treatment process and apparatus for hot galvanizing production line

A comprehensive treatment and plating flux technology, applied in hot-dip plating process, coatings, instruments, etc., can solve the problems of many tanks, not compact structure, large footprint, etc., achieve simple and compact structure of the device, and save raw materials , The effect of reducing production waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

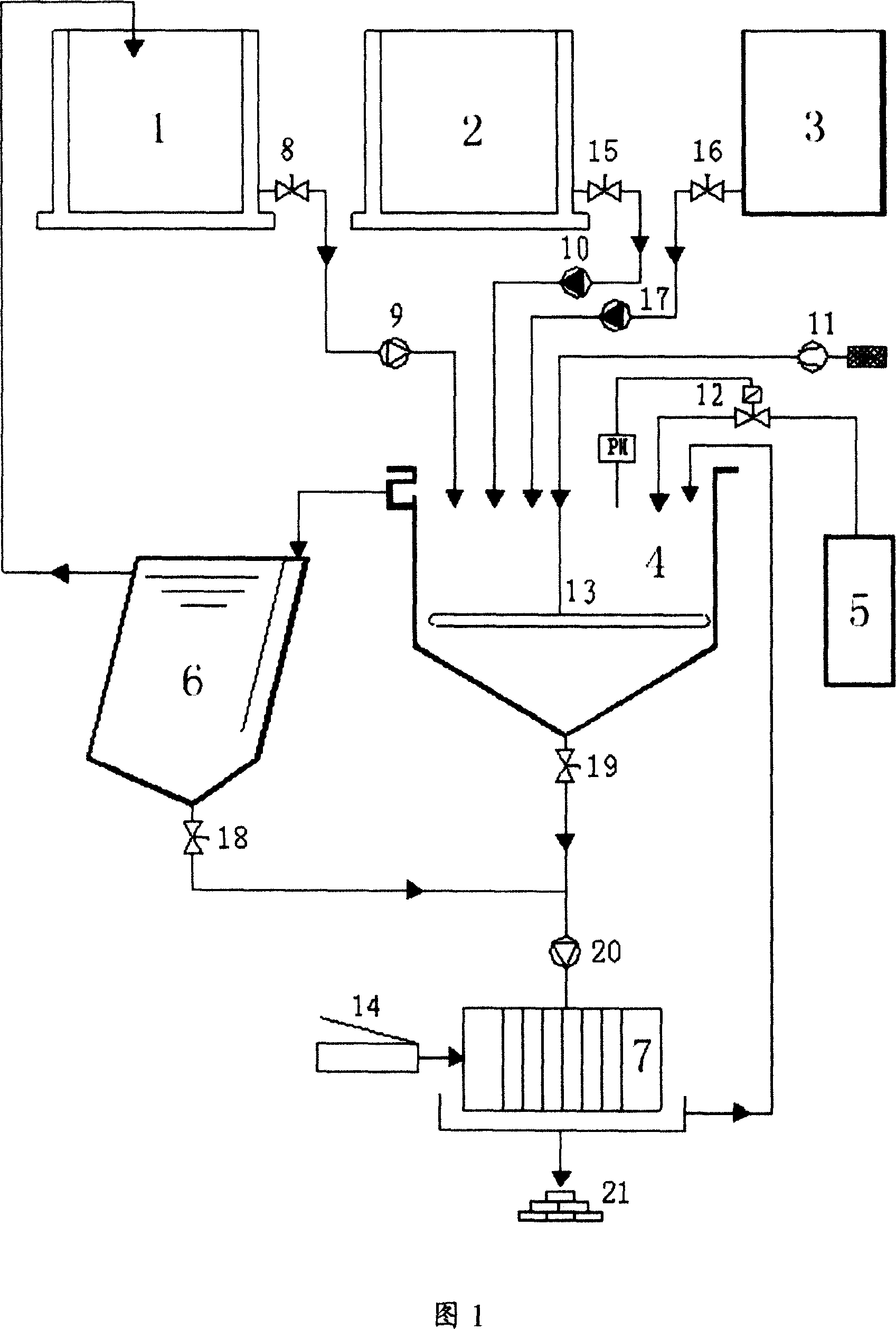

[0029] In Fig. 1: 1. Plating flux tank, 2. Dezincification tank, 3. Galvanized dust tank, 4. Treatment tank, 5. Ammonia water tank, 6. Inclined plate precipitator, 7. Plate and frame filter press, 8 , 15, 16, 18, 19. Valve, 9, 20. Pump, 10, 17. Metering pump, 11. Fan, 12. pH automatic measurement and control system, 13. Ring air duct, 14. Air compressor, 21. Dry mud.

[0030]In Fig. 1, the plating flux tank 1, valve 8, and pump 9 are connected with the treatment tank 4 through pipelines, and when the valve 8 was opened, the plating flux can be continuously pumped into the process tank 4; dezincification tank 2, valve 15, Metering pump 10 is connected with treatment tank 4 through pipeline, and when valve 15 is opened, the dezincification solution containing zinc chloride can be metered and flowed in treatment tank 4 as required; The treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com