Method for recovering lithium from lithium iron phosphate

A lithium iron phosphate and lithium recovery technology is applied in the field of lithium recovery to achieve good industrial application prospects, thorough impurity removal, and improved purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

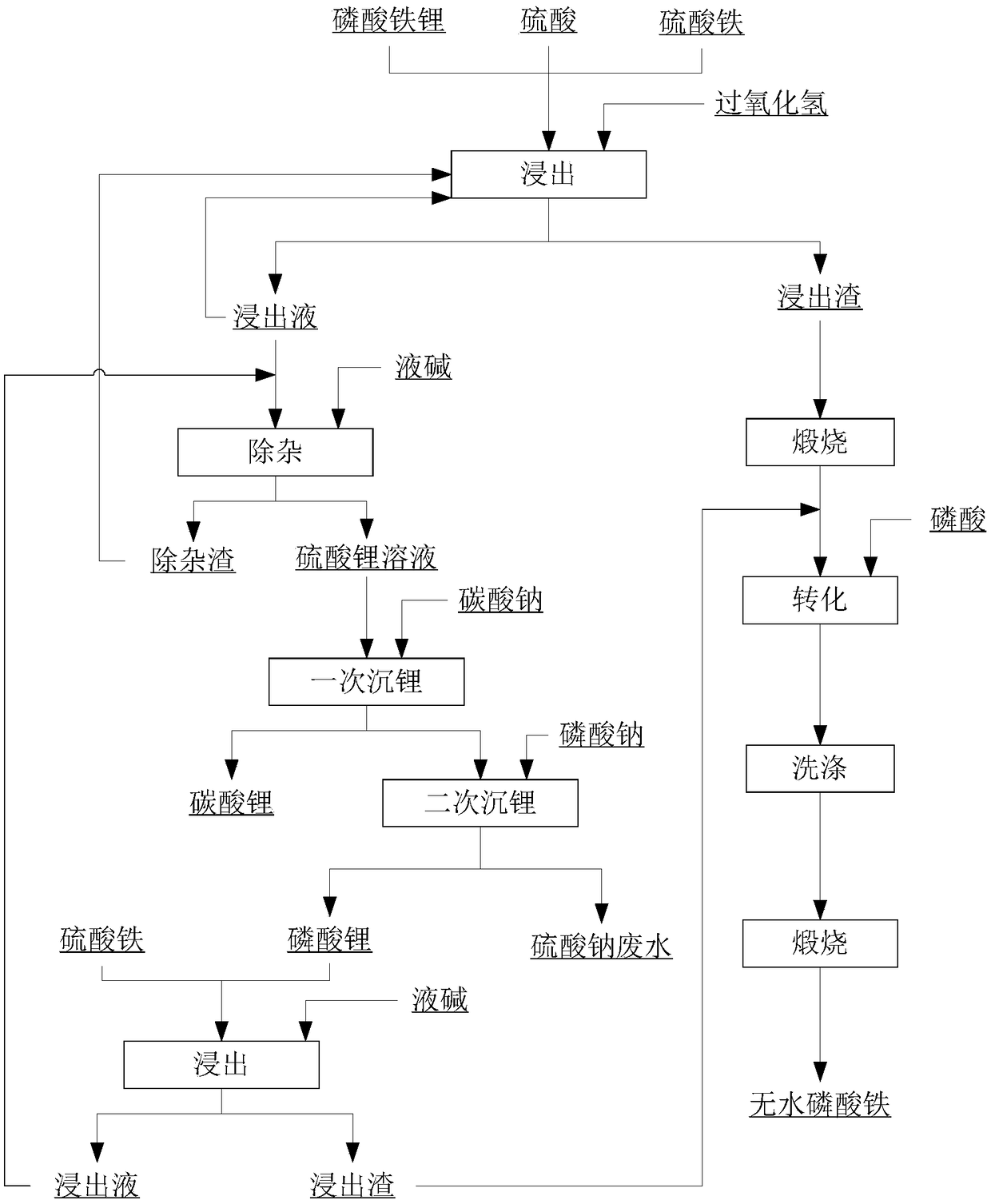

Image

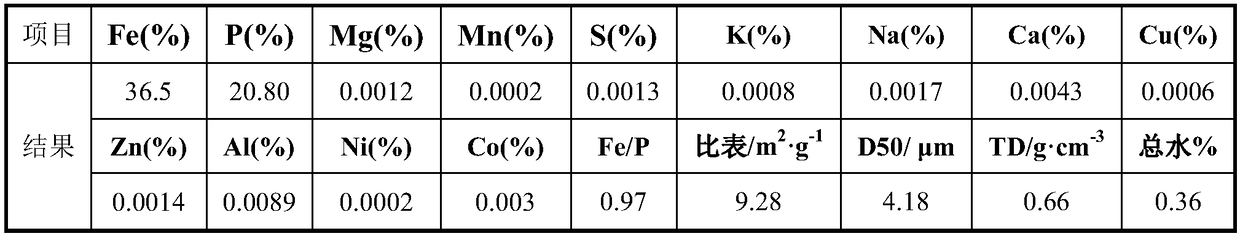

Examples

Embodiment

[0038] A part of the embodiments of the present invention, but not all the embodiments, based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without innovative work, all belong to the protection scope of the present invention.

[0039] 1) Make a slurry of lithium iron phosphate slag with a liquid-solid ratio of 7:1, add sulfuric acid and iron sulfate to the lithium iron phosphate slag made into the slurry and react for 2 hours to dissolve it into Li + , Fe 2+ 、PO 4 3- solution;

[0040] 2) in Li + , Fe 2+ 、PO 4 3- Add hydrogen peroxide in the solution, react 60min, the Fe in the slurry 2+ Oxidized to Fe 3+ , with PO in the slurry 4 3- Generate ferric phosphate precipitation and a small amount of ferric hydroxide precipitation, filter to obtain a lithium sulfate solution containing a small amount of iron;

[0041] 3) The iron-containing lithium sulfate solution is enriched repeatedly, and the lithium metal conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com