Kieselguhr modified adsorption material and preparation method and application thereof

An adsorption material, diatomite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem of low adsorption capacity, achieve simple preparation process, uniform loading, and improve adsorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

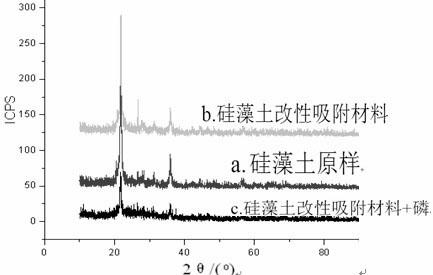

[0032] (1) Pretreat the surface of the diatomite carrier: soak the diatomite carrier in a mixed solution of hydrochloric acid and nitric acid with pH=0.01 at a ratio of solid-to-liquid mass ratio of 1:2, pickle for 2 hours under low-speed stirring, and pump Filter and rinse with distilled water until neutral, then dry at 110°C for 2 h, cool and put into sealed bags for later use;

[0033] (2) configure ferric chloride solution: take by weighing the ferric chloride of 16.25g, be dissolved in the water of 500ml and be configured into the ferric chloride solution that solubility is 0.2mol / L;

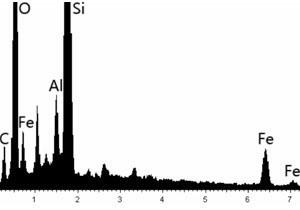

[0034](3) Prepare diatomite modified adsorption material by iron salt method: impregnate the diatomite carrier treated in step (1) into the ferric chloride solution in step (2), stir at a low speed to make it fully mixed, and control it at 70 ℃~80℃ for 24 hours, take it out and cool it to room temperature and wash off the unsupported iron oxyhydroxide particles with distilled water, then pu...

Embodiment 2

[0037] (1) Surface pretreatment of the diatomite carrier: operate according to the method in Example 1; wherein the surface of the diatomite carrier is pretreated: the diatomite carrier is soaked in the solid-liquid mass ratio of 1:5 In the mixed solution of hydrochloric acid and nitric acid with pH=0.5;

[0038] (2) configure ferric chloride solution: configure by the method in embodiment 1, FeCl 3 The concentration is 0.2mol / L;

[0039] (3) diatomite modified adsorption material prepared by iron salt method: operate according to the method in Example 1;

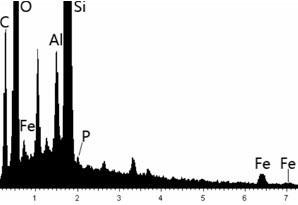

[0040] (4) Performance evaluation of diatomite modified adsorption material: Weigh 0.05g of the adsorption material in 7 times, place in 7 100mL Erlenmeyer flasks, add a solution with an initial phosphorus concentration of 2mg / L, and use HCl and KOH solutions in sequence Adjust the pH value of the phosphorus-containing solution to 3-9, put it into a constant temperature shaker, the rotation speed is 120r / min, the temperat...

Embodiment 3

[0042] (1) Surface pretreatment of the diatomite carrier: operate according to the method in Example 1, wherein the surface of the diatomite carrier is pretreated: the diatomite carrier is soaked in the solid-liquid mass ratio of 1:3 In the mixed solution of hydrochloric acid and nitric acid with pH=0.3;

[0043] (2) configure ferric chloride solution: configure by the method in embodiment 1, FeCl 3 The concentration is 0.2mol / L;

[0044] (3) diatomite modified adsorption material prepared by iron salt method: operate according to the method in Example 1;

[0045] (4) Performance evaluation of diatomite modified adsorption material: Weigh 0.05g of the adsorption material in 5 times, put it in five 100mL Erlenmeyer flasks, add a solution with an initial phosphorus concentration of 2mg / L, and adjust the pH value to about 6 , placed in 5 different constant temperature shakers, the temperature was set at 15°C, 20°C, 25°C, 30°C and 35°C in turn, the rotation speed was 120r / min, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com