Bottom water plugging agent system and process for horizontal well

A horizontal well and system technology, applied in the direction of sealing/isolation, wellbore/well components, drilling composition, etc., can solve the problems of lack of mature technology, etc., achieve reasonable selection, increase oil well productivity, and strong erosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

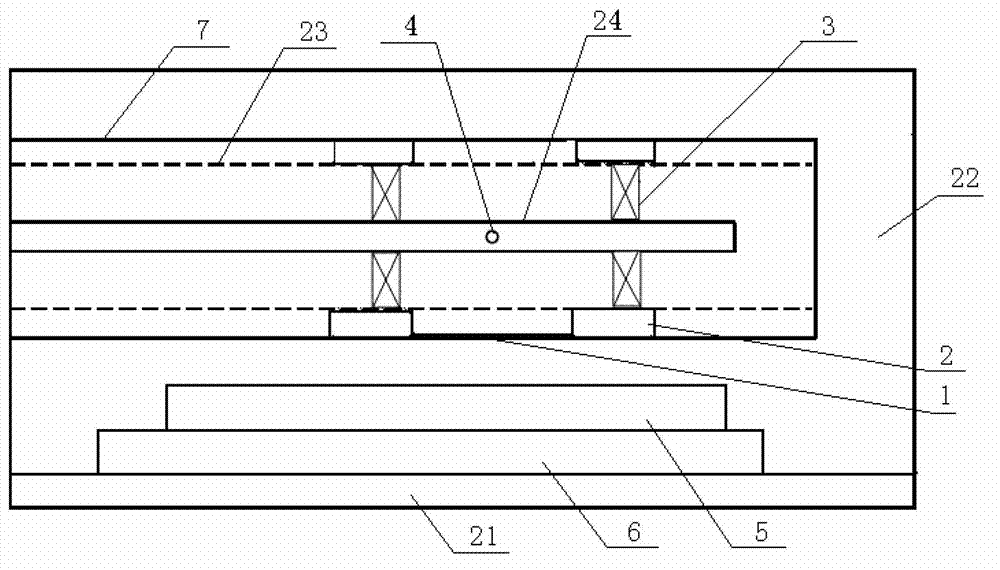

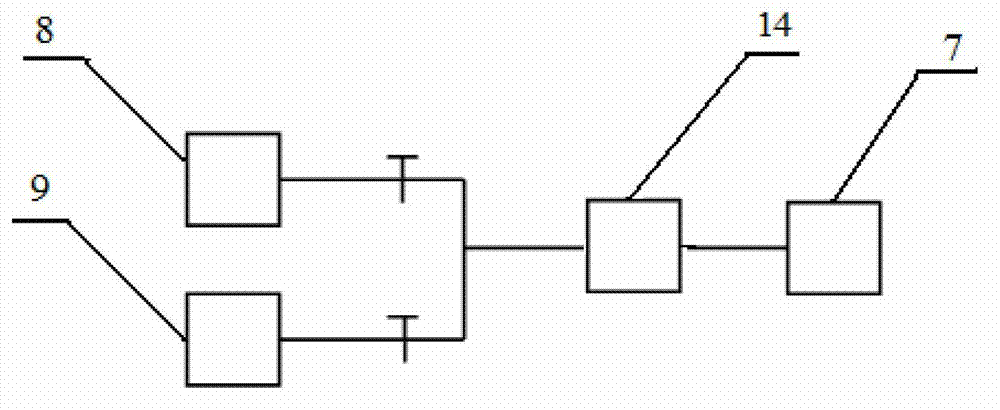

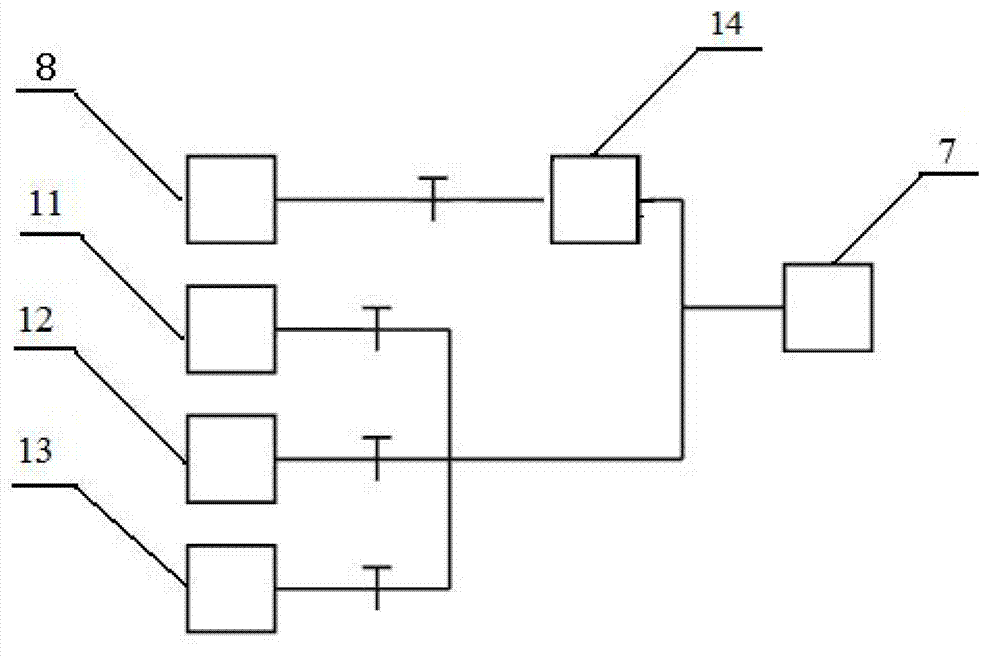

Image

Examples

preparation example Construction

[0058] The preparation method of the inorganic precipitation type system comprises the following steps:

[0059] (1) Put the oil field injection water into the mixing tank first, turn on the mixer in the tank, and the stirring speed is 100-200rpm;

[0060] (2) Add the inorganic precipitation system and slowly pour it in along the vortex stirred in (1);

[0061] (3) After stirring for 30 minutes, reduce the stirring speed to 50-80 rpm, continue stirring for 50 minutes, then stop stirring to obtain an inorganic precipitation type system, and the concentration of the prepared system is 5-35 wt%.

[0062] The preparation method of described polysilicon system or polymer jelly system comprises the following steps:

[0063] (1) Put the oil field injection water into the mixing tank first, turn on the mixer in the tank, and the stirring speed is 1000-2000rpm;

[0064] (2) Add polysilicon system or polymer jelly system and slowly pour in along the vortex stirred in (1);

[0065] (3...

Embodiment 1

[0076] Example 1: Conventional Horizontal Bottomhole Water Plugging Technology of Inorganic Precipitation System and Polymer Jelly System

[0077] A horizontal well bottom water plugging technology mainly includes two slugs, the first slug is an inorganic precipitation system and the second slug is a polymer jelly system with a volume ratio of 1:3.

[0078] The above-mentioned horizontal bottom hole water plugging technology includes the following steps:

[0079] (1) First put a certain amount of oilfield injection water into the mixing tank of the inorganic precipitation system, turn on the mixer in the tank, and the stirring speed is 100-200rpm;

[0080] (2) Add a certain amount of inorganic precipitation system and pour it slowly along the vortex stirred in (1);

[0081] (3) After stirring for 30 minutes, the stirring speed is reduced to 50-80 rpm, and the stirring is stopped after 50 minutes of continuous stirring to obtain a 5-35 wt% inorganic precipitation system;

[0...

Embodiment 2

[0087] Example 2: Conventional Horizontal Bottomhole Water Plugging Technology of Inorganic Precipitation System and Polysilicon System

[0088] A horizontal well bottom water plugging technology mainly includes two slugs, the volume ratio of the first slug inorganic precipitation system and the second slug polysilicon system is 2:1.

[0089] The above-mentioned horizontal bottom hole water plugging technology includes the following steps:

[0090] (1) First put a certain amount of oilfield injection water into the mixing tank of the inorganic precipitation system, turn on the mixer in the tank, and the stirring speed is 100-200rpm;

[0091] (2) Add a certain amount of inorganic precipitation system and pour it slowly along the vortex stirred in (1);

[0092] (3) After stirring for 30 minutes, the stirring speed is reduced to 50-80 rpm, and the stirring is stopped after 50 minutes of continuous stirring to obtain a 5-35 wt% inorganic precipitation system;

[0093] (4) Put a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com