Combined type separation device for scrap iron in grinding fluid

A separation device and grinding fluid technology, applied in the field of mechanical devices, to achieve good separation effect, speed up the precipitation process, and low iron filings content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

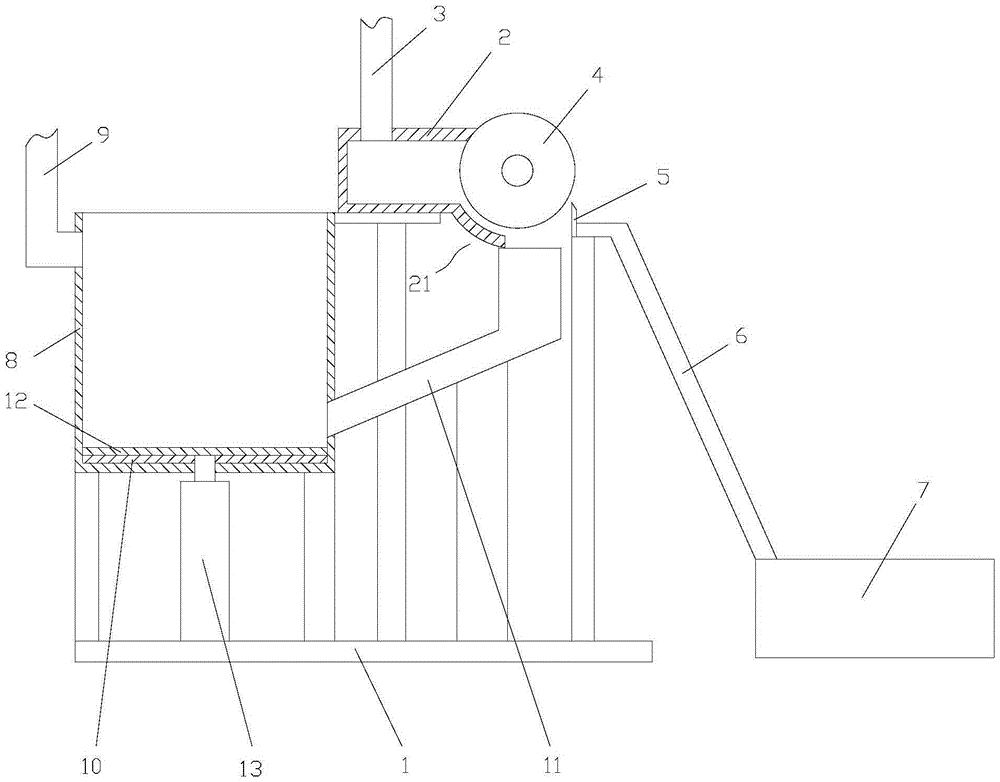

[0013] As shown in the figure, the combined grinding fluid iron filings separation device of this embodiment includes a frame 1, a magnetic roller separation device and a sedimentation separation device.

[0014] The magnetic roller separation device comprises a grinding liquid tank 2 arranged on the frame, an infusion tube 3 for sending the grinding liquid into the grinding liquid tank, and a magnet roller 4 arranged on the wall of the grinding liquid tank outlet end , the motor (not shown) that drives the rotation of the magnet roller, the scraper knife 5 that is arranged on the bottom of the magnet roller and fixed on the grinding fluid storage tank, the iron chip conveying groove 6 that is positioned at the bottom of the scraper knife, and is arranged on the The chip receiving box 7 at the end of the iron filings conveying chute;

[0015] The sedim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com