Five process methods for reducing precipitation type pores of aluminum alloy die casting parts

A die-casting process and aluminum alloy technology, which is applied in the field of reducing precipitated pores in aluminum alloy die-castings, to achieve the effect of reducing precipitated pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] 1. Process treatment of raw and auxiliary materials: Before using the furnace charge, carry out sand blowing treatment to remove rust, sediment and other dirt on the surface of the furnace charge, and then preheat the furnace charge. Bring in moisture and oil, etc.

[0008] 2. Treatment of smelting equipment: Before using a new crucible or an old crucible with rust and dirt, perform sand blasting to remove the crucible, ingot mold, and smelting tools, and preheat to 220-350°C for 2 hours, and the crucible continues Heat to 680°C-750°C and keep it warm for 1 hour; the newly built furnace must be dried in the oven for more than 3 days before use; the tools used for melting, such as ladles and bell jars for degassing, must be dried before use. Clean the residual metal, scale and other dirt on the surface.

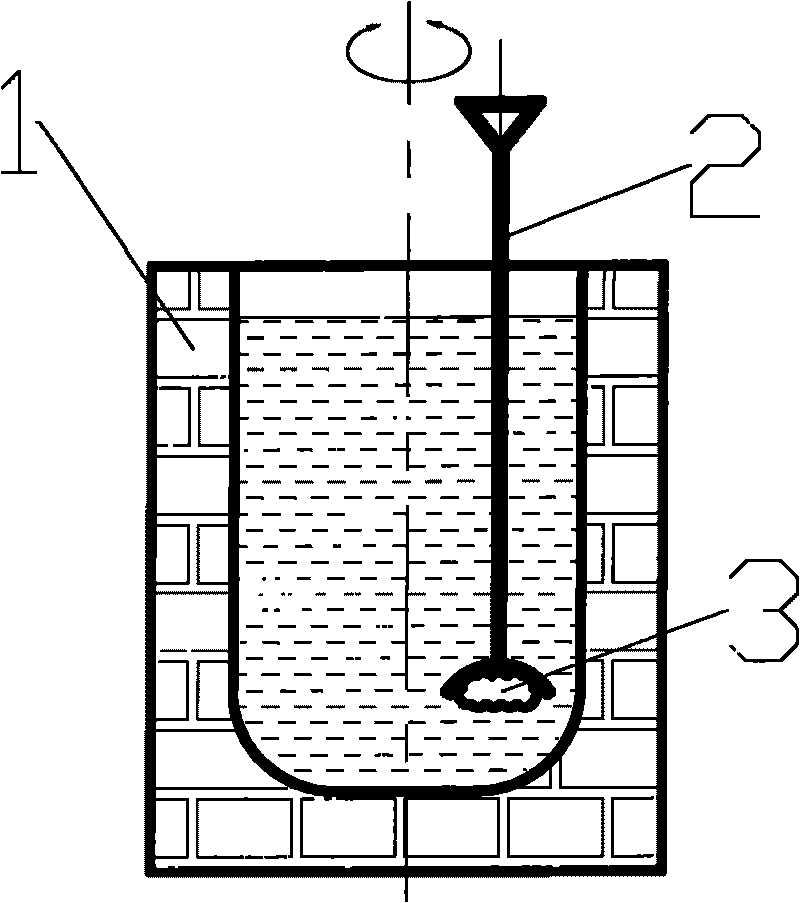

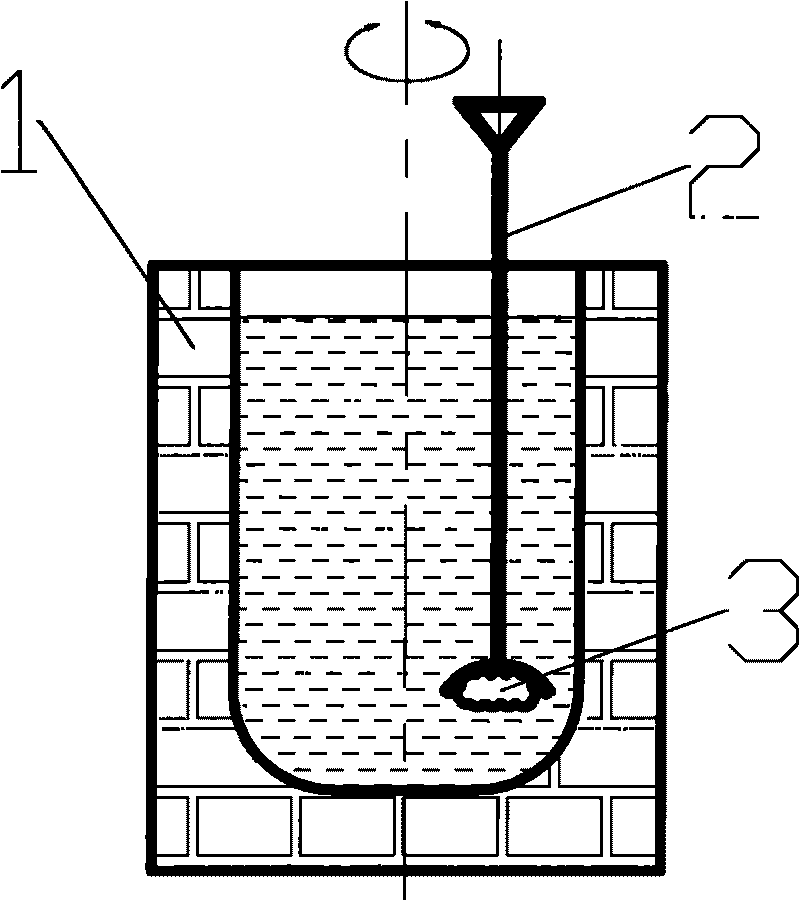

[0009] 3. Refining and degassing treatment: the refining degassing agent 3 is made of chlorine salt, the refining equipment is designed with a quarter spherical bell j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com