Carbide precipitation type rare earth carburizing steel

A carbide and precipitation-type technology, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of reduced mechanical properties of workpieces, coarse carbides and angular carbides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

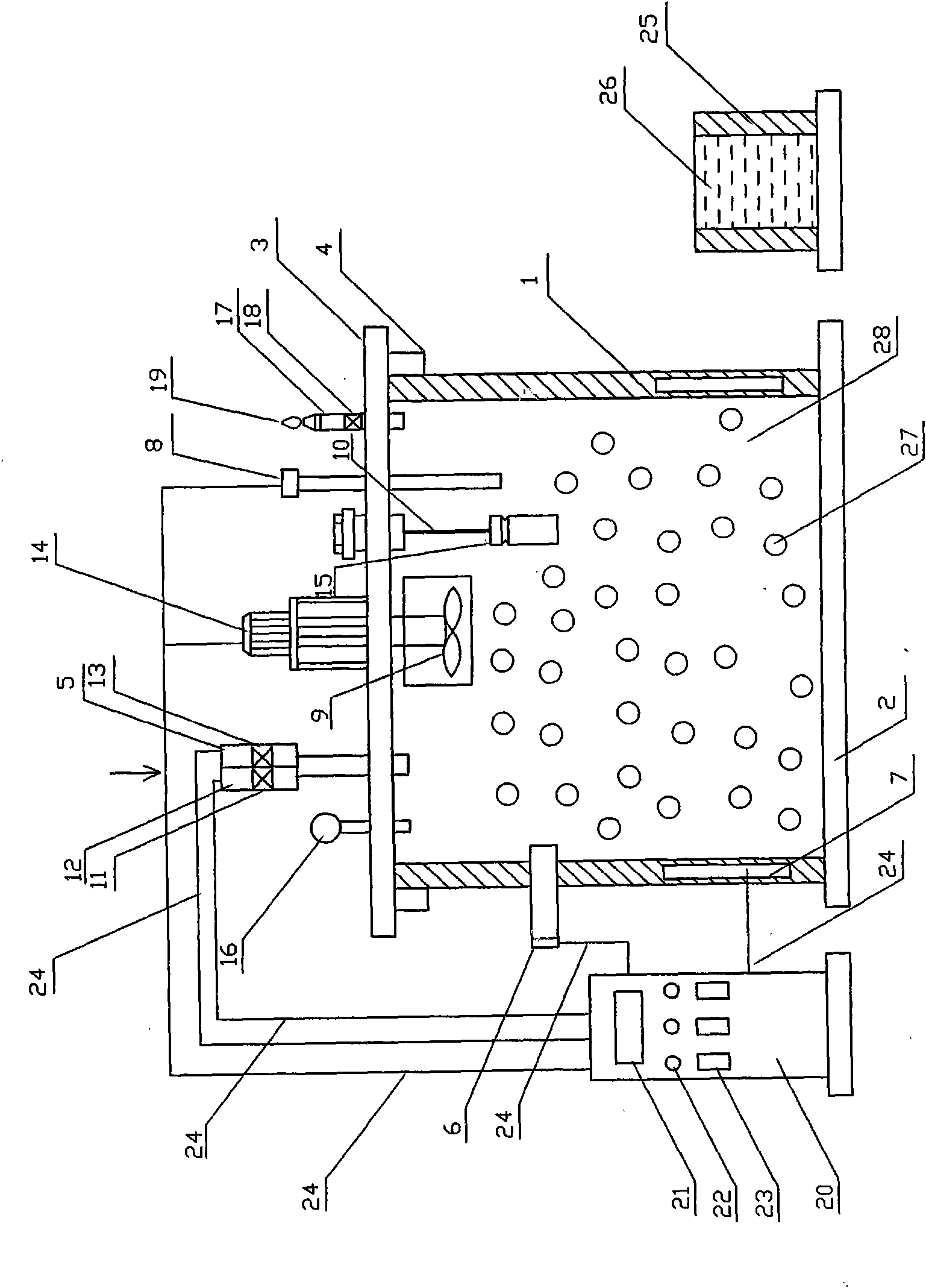

[0083] Carburizing is carried out in the carburizing furnace, and all parts of the carburizing furnace are in the quasi-working state;

[0084] Hoist the carbide precipitation type rare earth carburizing steel-30Cr4SiMoRE steel cooling drawn steel pipe mold in the carburizing furnace, close the carburizing furnace, open the exhaust hole, open the resistance heater, and the temperature in the carburizing furnace rises to 600℃~650℃ , turn on the fan in the carburizing furnace, continue to heat up to 750°C~760°C, turn on the methanol dropper, add methanol dropwise at a rate of 20~30ml / min, the gas expands after the methanol is cracked at high temperature, and the exhaust gas in the furnace is released from the exhaust hole Exhaust, then ignite the exhaust gas from the exhaust nozzle, continue to heat up to 920°C ± 5°C, keep warm for 30 minutes and fully exhaust the exhaust gas, the drop rate of methanol drops to 10-15ml / min, at the same time add isopropanol dropwise, and the oxyge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com