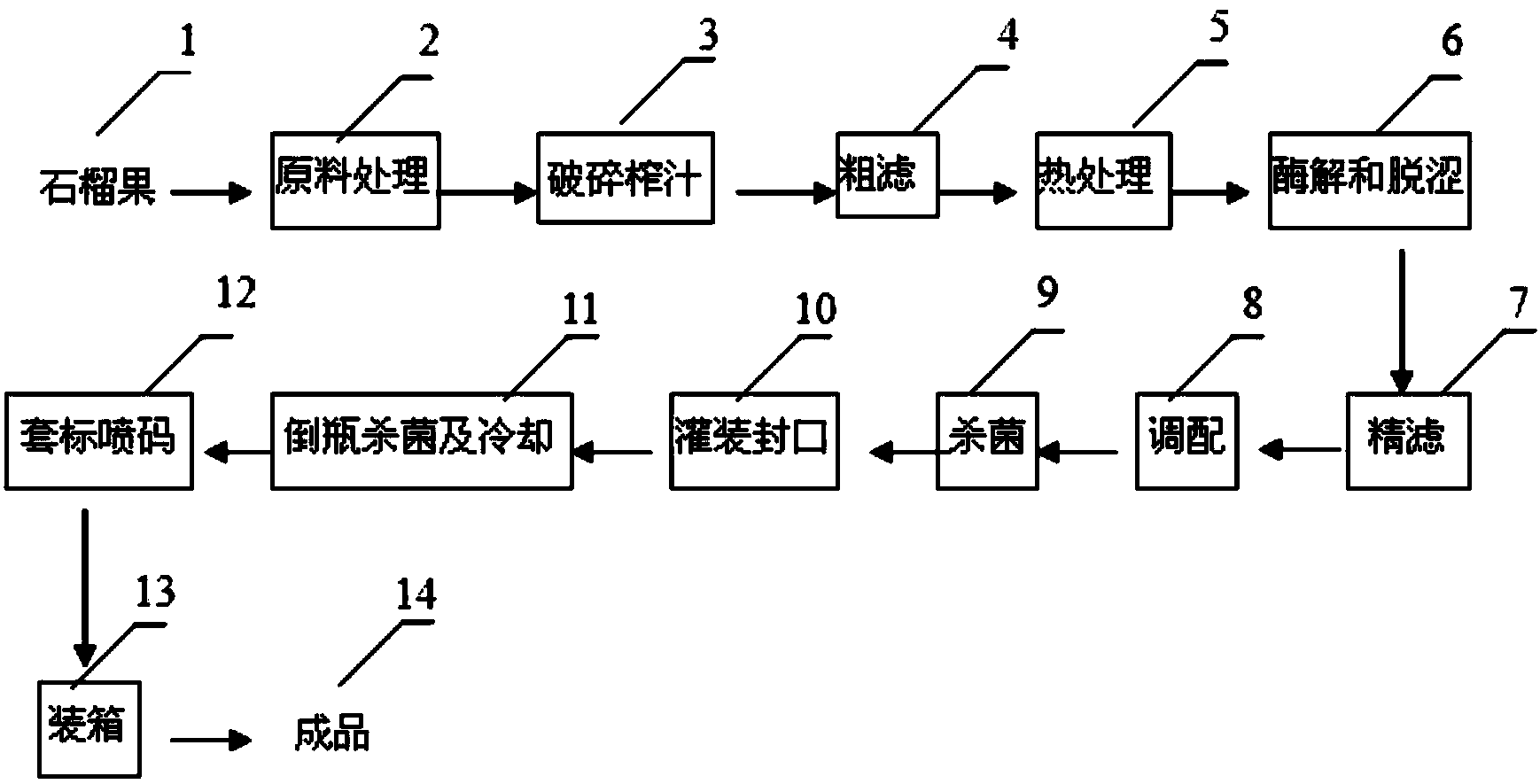

Pomegranate juice drink and production method thereof

A production method and technology for pomegranate juice, which are applied in the directions of food heat treatment, food ingredients as taste improvers, food science, etc., can solve problems such as troubled production enterprises, escape of aromatic substances, easy browning of pomegranate juice, etc. Reduce sedimentation problems and preserve flavor and character

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

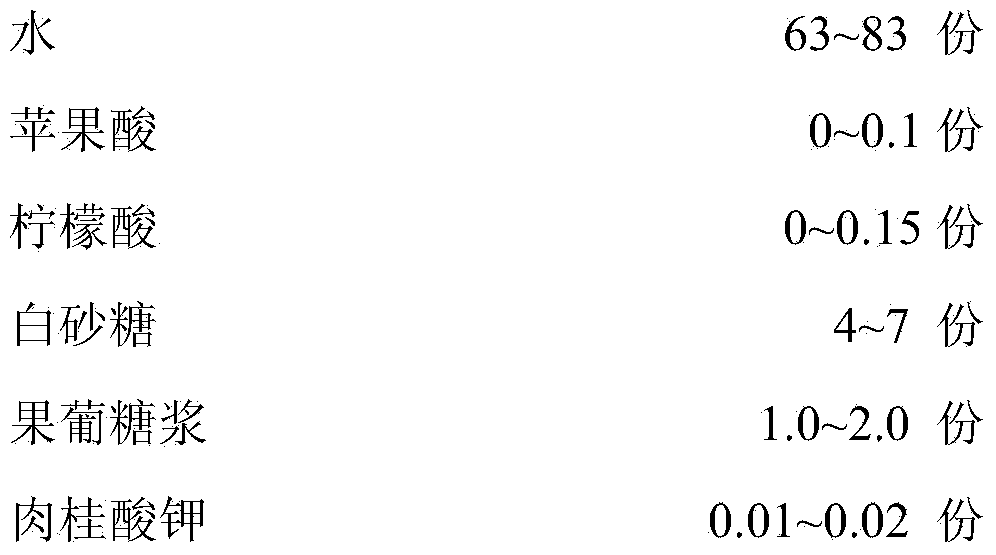

[0051] Select fresh pomegranate fruit, after manual selection, bubbling and cleaning, and remove the outer skin, the pomegranate seeds obtained are sent to a continuous screw press for crushing and squeezing; the obtained juice is filtered through a double filter with a pore size of 300 mesh; the filtrate Pump into the heat exchanger, heat-treat at 90°C for 10s, cool to 45°C, pump into the enzymolysis insulation tank; add 0.05 parts of pectinase and 20 parts of gelatin solution with a concentration of 1% to 1000 parts of heat-treated pomegranate slurry , at a speed of 20rpm, react at a temperature of 45°C for 1h; first filter the enzymatically hydrolyzed pomegranate juice with a bag filter with a pore size of 0.8μm, and then filter it with a hollow fiber membrane of 0.15μm; mix 4 parts of white sugar, fruit Add 2 parts of glucose syrup to 35 parts of treated purified water to dissolve, filter through a diatomaceous earth filter and pump into the batching tank; add 0.15 parts of...

Embodiment 2

[0053]Select fresh pomegranate fruit, after manual selection, bubbling cleaning, and removing the outer skin, the pomegranate seeds obtained are sent to a continuous screw press for crushing and squeezing; the obtained juice is filtered through a double filter with a pore size of 200 mesh; the filtrate Pump into the heat exchanger, heat-treat at 90°C for 20s, cool to 42°C, pump into the enzymolysis insulation tank; add 0.2 parts of pectinase and 30 parts of gelatin solution with a concentration of 1% to 1000 parts of heat-treated pomegranate slurry , at a speed of 10rpm, reacted at a temperature of 42°C for 3h; the enzymatically hydrolyzed pomegranate juice was first filtered through a bag filter with a pore size of 5μm, and then finely filtered with a hollow fiber membrane of 0.45μm; 7 parts of white sugar, fruit grape 1 part of syrup, dissolved in 35 parts of treated purified water, filtered through diatomaceous earth filter and pumped into the batching tank; 0.1 part of mali...

Embodiment 3

[0055] Select fresh pomegranate fruit, after manual selection, bubbling and cleaning, and removing the outer skin, the pomegranate seeds obtained are sent to a continuous screw press for crushing and squeezing; the obtained juice is filtered through a double filter with a pore size of 250 mesh; the filtrate Pump into the heat exchanger, heat-treat at 90°C for 15s, cool to 47°C, pump into the enzymolysis insulation tank; add 0.1 part of pectinase and 25 parts of gelatin solution with a concentration of 1% to 1000 parts of heat-treated pomegranate slurry , at a speed of 15rpm, react at a temperature of 47°C for 2h; first filter the enzymatically hydrolyzed pomegranate juice with a bag filter with a pore size of 2μm, and then filter it with a hollow fiber membrane of 0.22μm; mix 5 parts of white sugar, fruit grape 2 parts of syrup, dissolved in 30 parts of treated purified water, filtered through diatomaceous earth filter and pumped into the batching tank; 0.1 parts of citric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com