Sugar-free radix puerariae clear juice drink and production method thereof

A production method and technology of kudzu root, applied in sugar-free kudzu root juice beverage and its production field, can solve problems such as low dissolution rate of flavonoids, turbidity or precipitation of beverage products, affecting product sensory quality, etc., so as to improve juice yield and extend shelf life , to avoid the effect of precipitation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

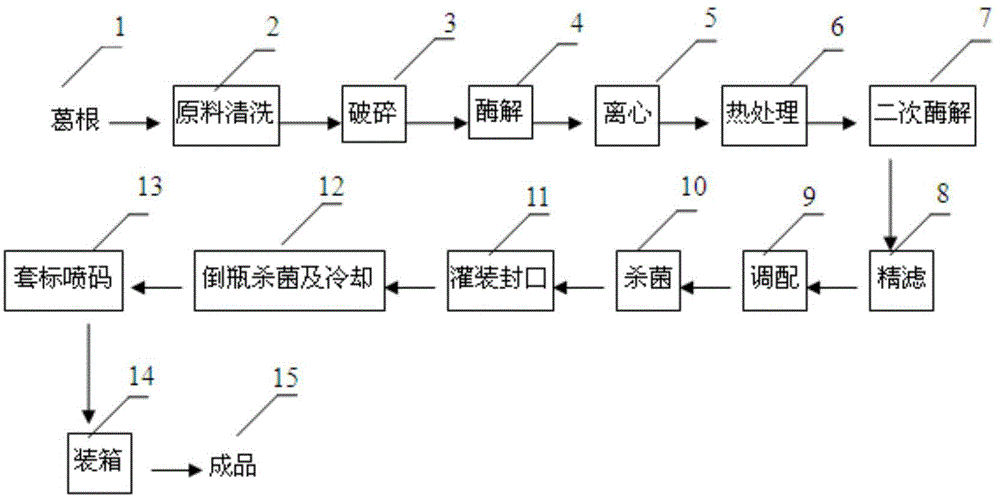

Method used

Image

Examples

Embodiment 1

[0058]Clean the fresh pueraria root and send it to the crusher, add an aqueous solution containing 0.03% sodium erythorbate twice as much as the pueraria root for crushing; pump the pueraria root paste into a stainless steel enzymatic insulation tank; add 0.3 parts of pectinase and 0.05 parts of amylase Among the 1000 parts of kudzu root paste obtained from the above crushing, react at a temperature of 50° C. for 1.5 h at a rotational speed of 10 rpm; pump the kudzu root paste after enzymolysis into a centrifuge for centrifugation, and then filter the kudzu root juice with a filter to obtain kudzu root juice Pueraria root juice is pumped into a heat exchanger, heat-treated at 90°C for 20s, cooled to 50°C, and pumped into a stainless steel enzymolysis insulation tank; React at a temperature of 50°C for 3 hours at a rotating speed; add 2 parts of bentonite, stir evenly and let it stand for 4 hours; filter the kudzu root juice after enzymolysis with a diatomaceous earth filter to ...

Embodiment 2

[0060] Clean the fresh kudzu root and send it to the crusher, add an aqueous solution containing 0.1% citric acid twice the amount of kudzu root for crushing; pump the kudzu root paste into a stainless steel enzymolysis insulation tank; add 0.5 parts of pectinase and 0.1 part of amylase to the above In 1000 parts of kudzu root paste obtained by crushing, react at a temperature of 45° C. for 1 h at a speed of 30 rpm; pump the kudzu root paste after enzymolysis into a centrifuge for centrifugation, and then filter the kudzu root juice with a filter to obtain kudzu root juice; The juice is pumped into a heat exchanger, heat-treated at a temperature of 90°C for 15s, cooled to 45°C, and pumped into a stainless steel enzymolysis insulation tank; in parts by weight: add 0.2 parts of pectinase and 0.05 parts of amylase to 1000 parts of kudzu root juice, Under the rotation speed of 20rpm, react at a temperature of 45°C for 2h; add 3 parts of bentonite, stir evenly and let it stand for 3...

Embodiment 3

[0062] Clean the fresh pueraria root and send it to the crusher, add an aqueous solution containing 0.01% sodium erythorbate and 0.05% citric acid twice the amount of pueraria root for crushing; pump the pueraria root paste into a stainless steel enzymolysis insulation tank; mix 0.4 parts of pectinase with Add 0.05 parts of amylase to 1000 parts of kudzu root paste obtained from the above crushing, and react at a temperature of 48°C for 1.5 h at a speed of 20 rpm; the kudzu root paste after enzymolysis is pumped into a centrifuge for centrifugation, and the kudzu root liquid is then filtered. Filtrate to obtain kudzu root juice; pump the kudzu root juice into a heat exchanger, heat-treat at a temperature of 90°C for 17s, cool to 48°C, and pump it into a stainless steel enzymatic hydrolysis insulation tank; add 0.15 parts of pectinase and 0.03 parts of amylase to 1,000 parts of kudzu root juice 2.5 hours at a temperature of 48°C at a rotational speed of 15 rpm; then add 2.5 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com