Pure walnut fermented milk and a production method thereof

A production method and technology for fermented milk, which are applied in the field of pure walnut fermented milk and its production, can solve the problems such as inability to taste pure walnut fermented milk, unstable taste of fermented product batches, change of pure walnut fermentation, etc. The fermentation process is unstable, the carbon source and nitrogen source ratio is suitable, and the taste is stable and uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

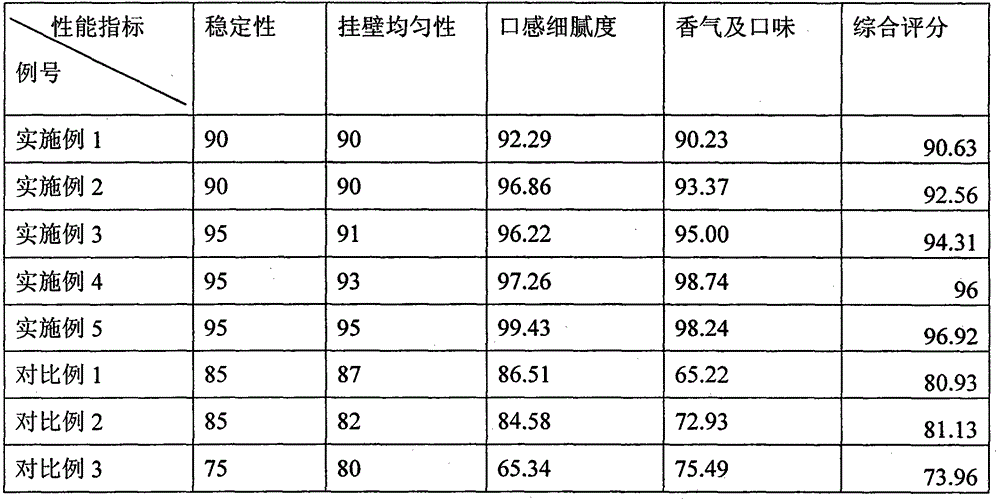

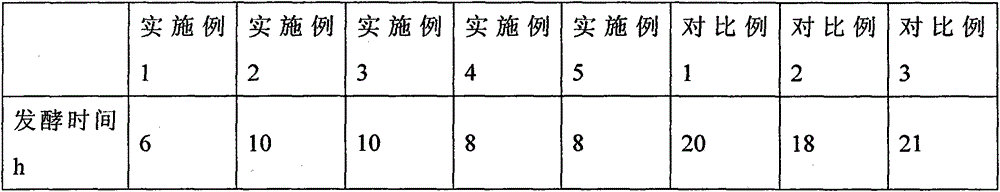

Examples

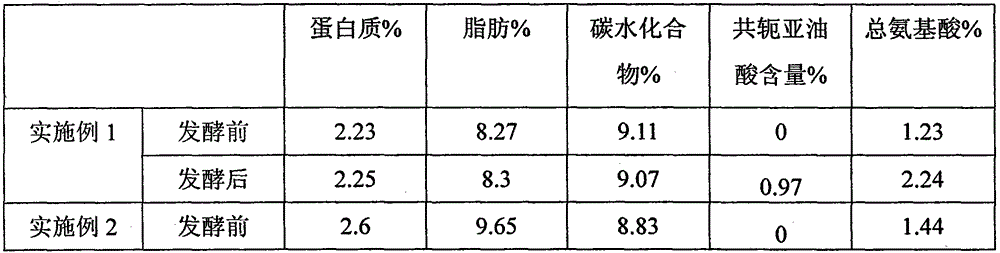

Embodiment 1

[0050] Step 1, peeling: According to the mass ratio of material to liquid: 1:4, quickly add 150kg of walnut kernels into 600kg of caustic soda aqueous solution with a mass fraction of 4% at 95°C, heat and stir at 90-95°C for 4 minutes, and then quickly discharge the Caustic soda solution, wash the skin with pure water, remove the walnut skin;

[0051] Step 2. Refining: add 450L of demineralized water at 70-90°C to the walnut kernels that have been peeled off in step 1 according to the mass-volume ratio of feed to liquid 1kg:3L, and use multiple colloid mills in series at 70-90°C Carry out step-by-step refining and refining, then add demineralized water at 70-90°C with 10% of the slurry volume, cut at a high speed of 1400r / min for 15min, further refine and reduce the particle size, and obtain walnut slurry;

[0052] Step 3, sugar melting: Weigh 30kg of sucrose and 50kg of glucose for a total of 80kg, according to the mass ratio of material to liquid 1:1, add 80kg of demineraliz...

Embodiment 2

[0061] Step 1, peeling: According to the mass ratio of material to liquid: 1:3, quickly add 175kg of walnut kernels into 525kg of 95°C aqueous caustic soda solution with a mass fraction of 5%, heat and stir at 90-95°C for 6 minutes, and quickly discharge the Caustic soda solution, wash the skin with pure water, remove the walnut skin;

[0062] Step 2. Refining: add demineralized water at 70-90°C to the walnut kernels that have been peeled in step 1 according to the mass-to-volume ratio of material to liquid: 1kg: 2.8L, and use multiple colloid mills in series at 70-90°C Carry out step-by-step refining and refining, then add demineralized water at 70-90°C with 5% of the slurry volume, and further refine and reduce the particle size by shearing at a high speed of 1400r / min for 20min to obtain walnut slurry;

[0063] Step 3, sugar melting: Weigh 25kg of sucrose and 50kg of glucose, 75kg in total, according to the mass ratio of material to liquid 1:0.8, add 60kg of demineralized w...

Embodiment 3

[0072] Step 1, peeling: According to the mass ratio of material to liquid 1:3, quickly add 200kg of walnut kernels into 600kg of 95°C caustic soda aqueous solution with a mass fraction of 3%, heat and stir at 90-95°C for 5 minutes, and then quickly discharge the Caustic soda solution, wash the skin with pure water, remove the walnut skin;

[0073] Step 2. Refining: add demineralized water at 70-90°C to the walnut kernels that have been peeled off in step 1 according to the mass-volume ratio of material to liquid: 1kg: 2.0L, and use multiple colloid mills in series at 70-90°C Carry out step-by-step refining and refining, then add demineralized water at 70-90°C with 10% of the slurry volume, and further refine and reduce the particle size by shearing at a high speed of 1600r / min for 10min to obtain walnut slurry;

[0074] Step 3, sugar: Weigh 30kg of sucrose and 30kg of glucose, 60kg in total, according to the mass ratio of material to liquid 1:1.5, add 90kg of demineralized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com