Semi-automatic peeling and slicing device for luffa acutangula roxb

A semi-automatic technology for peeling and slicing, applied in the fields of vegetable or fruit peeling, metal processing, food science, etc., it can solve the problems of unclean peeling, time-consuming, affecting taste, etc., and achieves easy cooking, convenient operation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now do further detailed explanation in conjunction with accompanying drawing.

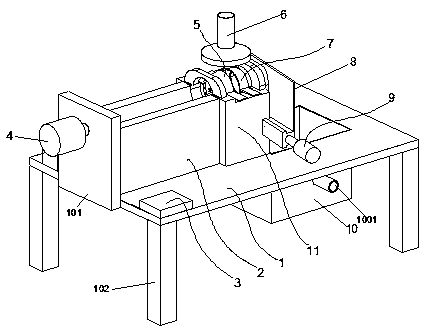

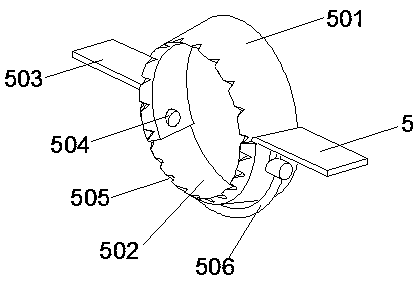

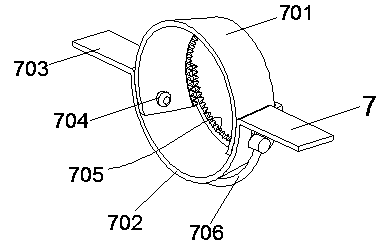

[0023] Such as Figures 1 to 5 As shown, a semi-automatic peeling and slicing device for ribbed loofahs, including a machine frame 1, a feeding seat 2, a control panel 3, a hydraulic cylinder 4, an edge removal ring 5, water sprinkling 6, a skin scraping ring 7, and a slicer 8. B hydraulic cylinder 9, material box 10, base 11.

[0024] Such as Figure 1-5 As shown, the setting frame 1 is provided with a mounting plate and 4 feet 102. The feeding mechanism includes a discharge seat 2 and a hydraulic cylinder 4. The discharge seat 1 is a square body, and an arc-shaped discharge trough is opened on the upper end. The center of the A hydraulic cylinder 4 is consistent with the center of the discharge trough. The peeling mechanism and slicer are installed on the right end. mechanism.

[0025] The peeling mechanism is set to include edge removal ring 5, water sprinkling 6, scraping ring 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com