Rotating cylinder type ginger fire process peeling device

A drum and ginger technology, applied in the peeling of vegetables or fruits, food science, applications, etc., can solve the problems of environmental protection, affect the taste, and pollute the environment with waste liquid, achieve good industrialization and facilitate continuous mechanical operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

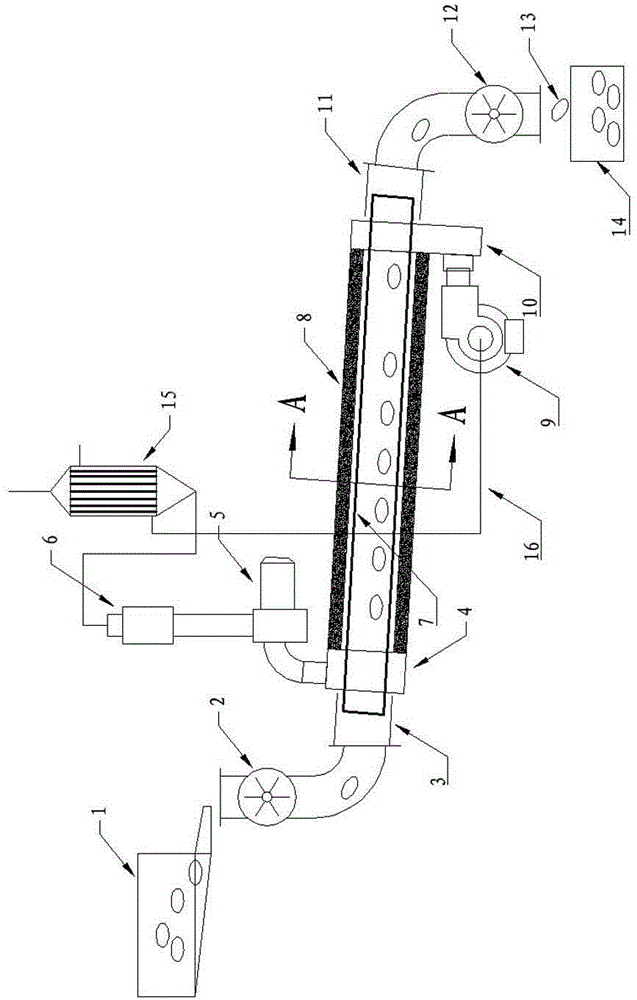

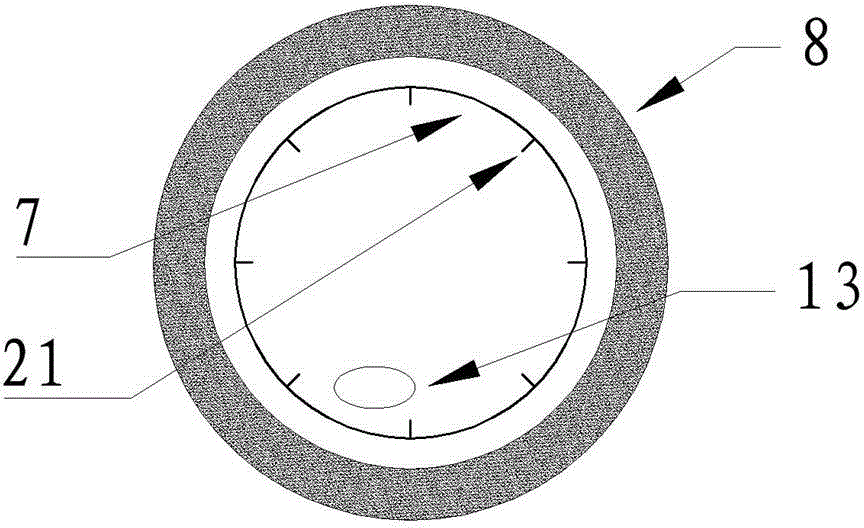

[0021] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0022] like figure 1 and figure 2 The drum-type ginger fire peeling device shown includes a drum 7 and a burner 9. The flame outlet of the burner is connected to the drum 7 through a gas distribution hood 10. The drum 7 is arranged obliquely, and the flame and the ginger 13 form a reverse motion. Rotating cylinder 7 is provided with tail gas hood 4, and tail gas hood is connected fan exhaust port 6 through suction fan 5, and fan exhaust port 6 is connected to the tube side of tube heat exchanger 15 and is emptied, and the upper tube of tube heat exchanger 15 is emptied. The shell side is connected to the atmosphere, and the lower shell side is connected to the burner 9; the discharge end of the drum is provided with a joint 11 connected to the drum discharge valve 12, and the lower end of the drum discharge valve 12 is provided with a water tank 14; the feed end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com