Apple processing equipment for food production

A processing equipment and apple technology, which is applied in the field of apple processing equipment for food production, can solve the problems of low work efficiency, low safety of peeling and coring, etc., and achieve the effect of improving work efficiency and facilitating work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

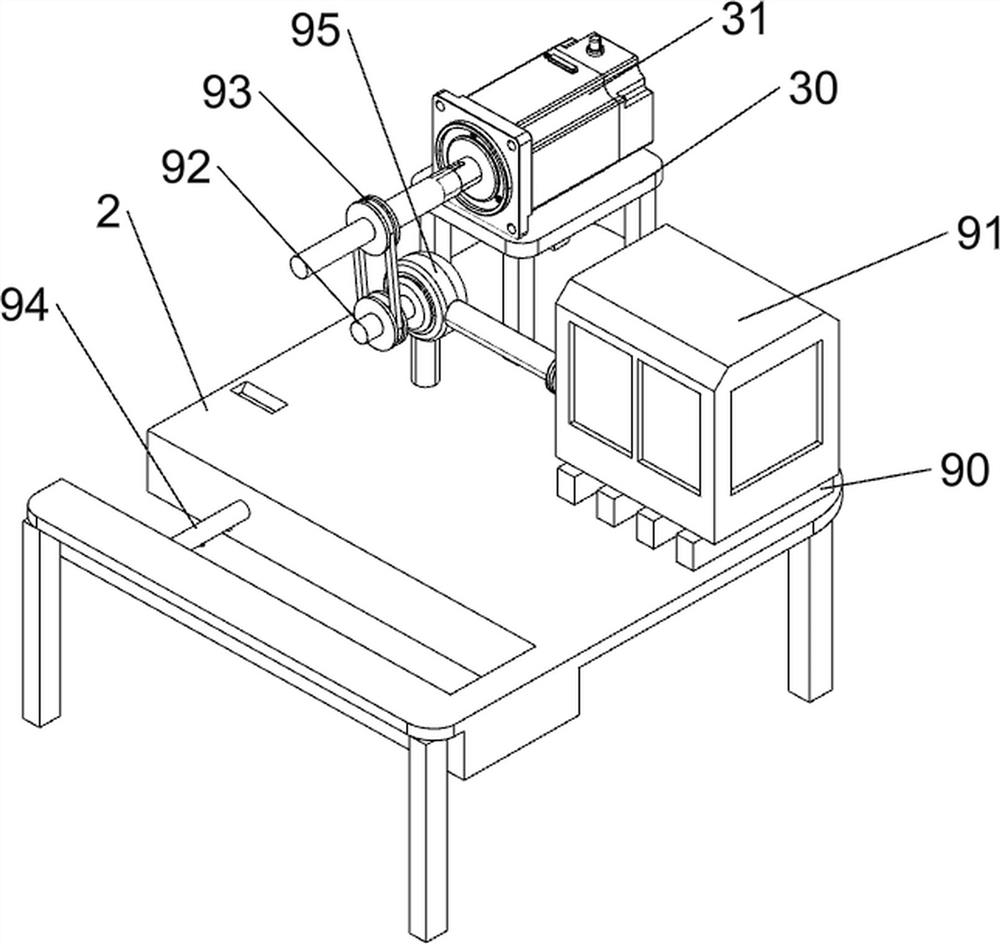

[0089] An apple processing equipment for food production, such as figure 1 As shown, it includes a bottom plate 1, a workbench 2, a turntable mechanism 3, a sliding mechanism 4 and a storage box 5. The top of the bottom plate 1 is provided with a workbench 2, and the upper part of the workbench 2 is provided with a turntable mechanism 3. The upper part of the workbench 2 is connected with the turntable mechanism. A sliding mechanism 4 is arranged between 3, and a storage box 5 is arranged in the middle of the top front side of the bottom plate 1.

[0090] When people need to peel apples, they first put the apples on a certain part of the turntable mechanism 3, then start a certain part of the turntable mechanism 3, the turntable mechanism 3 drives the apples to rotate, and the sliding mechanism 4 peels the apples. Apple peels fall down in the storage box 5, then the peeled apples are taken off, and the device runs repeatedly. After all the apples are peeled, a certain part of ...

Embodiment 2

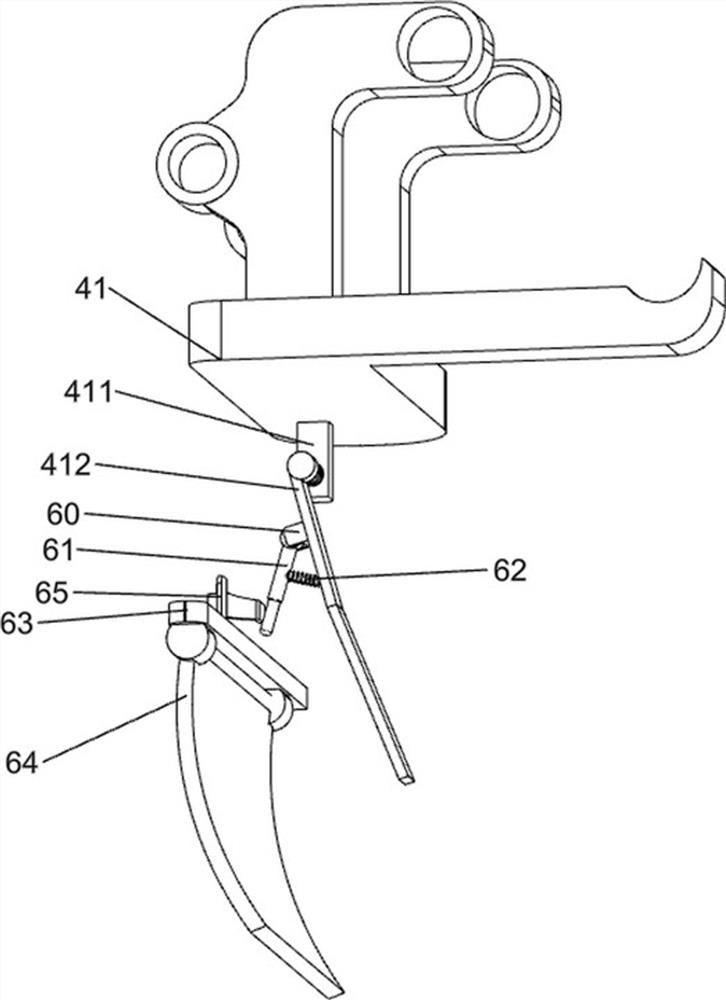

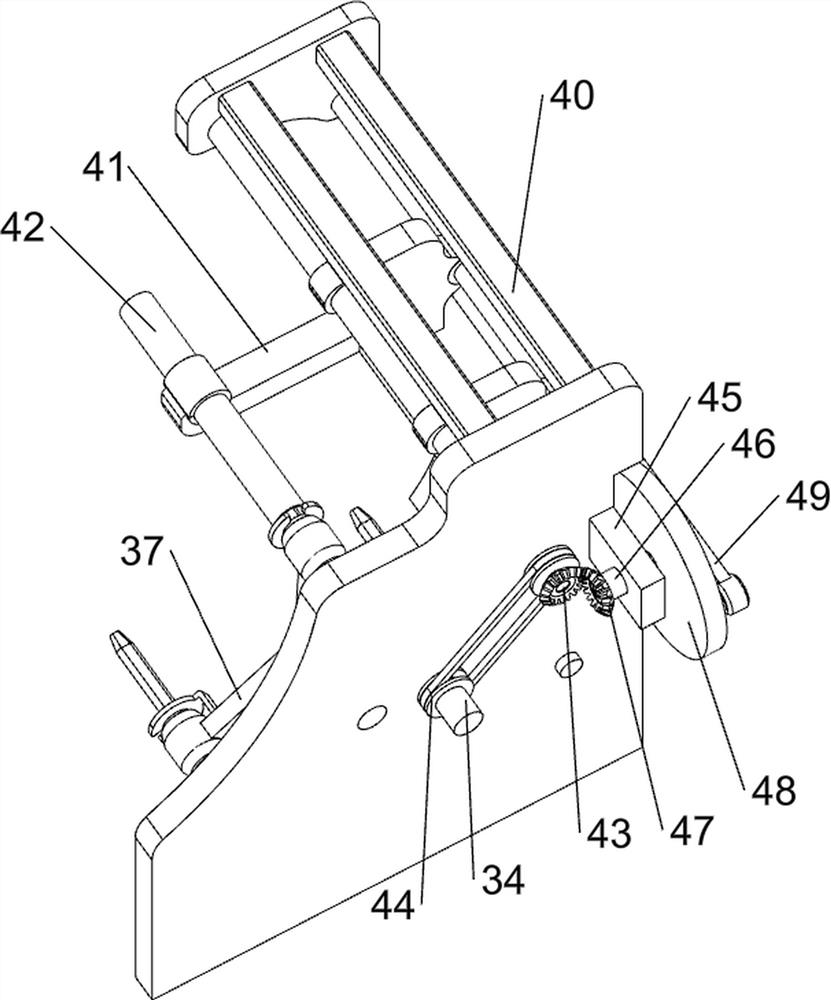

[0092] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the turntable mechanism 3 includes a motor bracket 30, a transmission motor 31, a first rotating shaft 32, a spur gear assembly 33, a second rotating shaft 34, a first pulley assembly 35, a dial 36, a rotating disk 37, and a dial 38 , the first spur gear 39, the insertion rod 310, the fixed block 311 and the second spur gear 312, the left rear part of the top of the workbench 2 is provided with a motor support 30, the top of the motor support 30 is provided with a transmission motor 31, and the transmission motor 31 The front end of the output shaft passes through the left side of the upper part of the workbench 2, and the upper left side of the rear side of the workbench 2 is provided with a first rotating shaft 32, and a spur gear assembly is arranged between the front part of the first rotating shaft 32 and the front part of the output shaft of the transmission motor 31 33....

Embodiment 3

[0099] On the basis of Example 2, such as Image 6 , Figure 7 , Figure 8 and Figure 9 As shown, a slicing assembly 7 is also included, and the slicing assembly 7 includes a cutter 70, a fixed frame 71 and a second baffle plate 72, the hollow rod 42 rear portion is evenly provided with a cutter 70, and the middle of the upper part of the front side of the workbench 2 is left-right symmetrical. A fixing frame 71 is provided, and a second baffle 72 is arranged between the front ends of the fixing frame 71 , and the second baffle 72 is slidably connected with the hollow rod 42 and the cutter 70 .

[0100] When the hollow rod 42 moves backwards to remove the core of the apple, the hollow rod 42 drives the cutter 70 to move backwards, and the cutter 70 slices the apple. When the hollow rod 42 moves forward, it drives the cutter 70 to move forward. Under the effect of the second baffle plate 72, the apple is separated from the cutter 70, and the sliced apples fall down.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com