Power lead peeling device

A lead wire and electric power technology, which is applied in the field of power lead wire stripping device, can solve the problems of processing cable damage, operator hand injury, internal copper core protection is not in place, etc., to achieve complete peeling, high reliability, and increase yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the drawings:

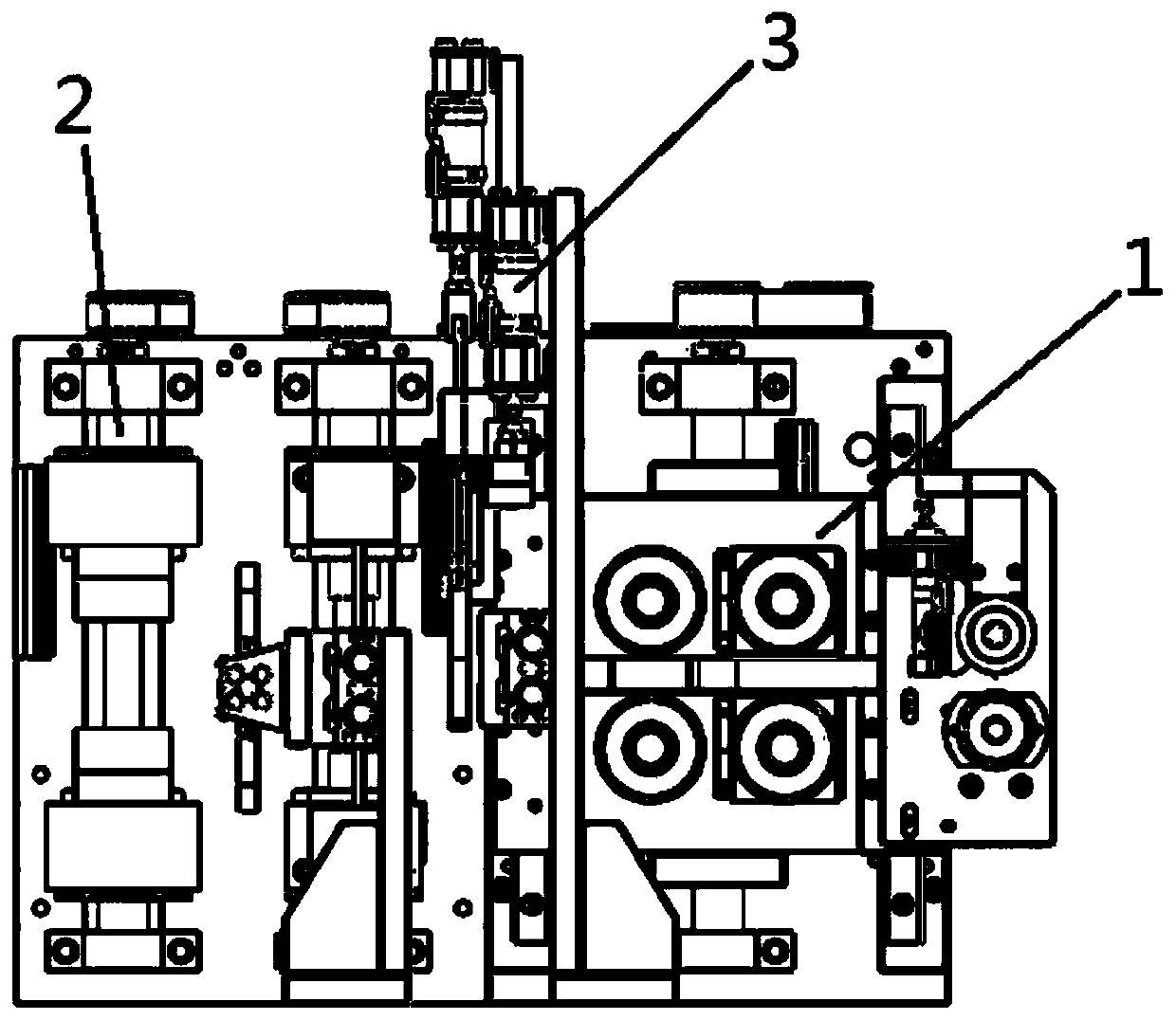

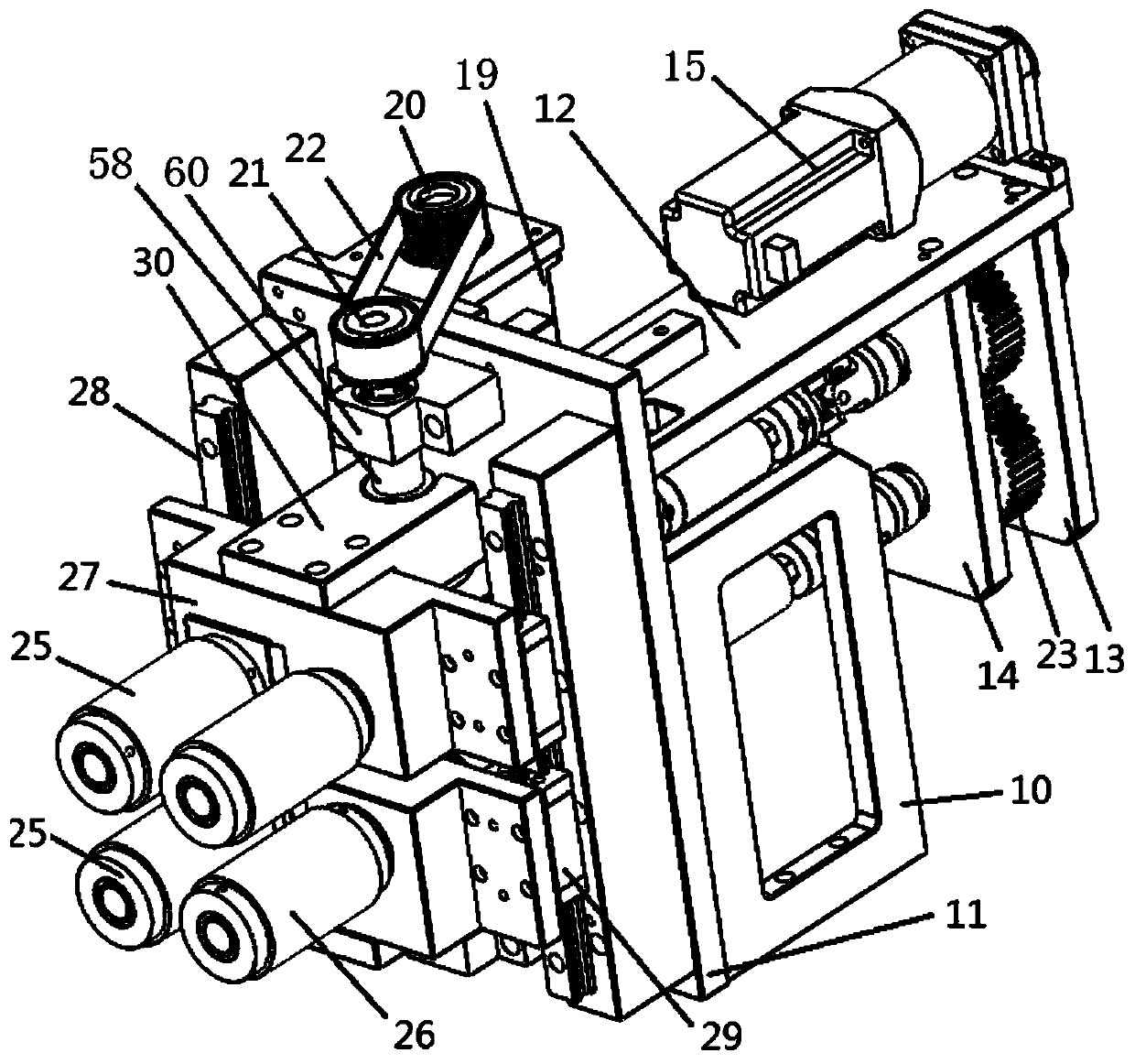

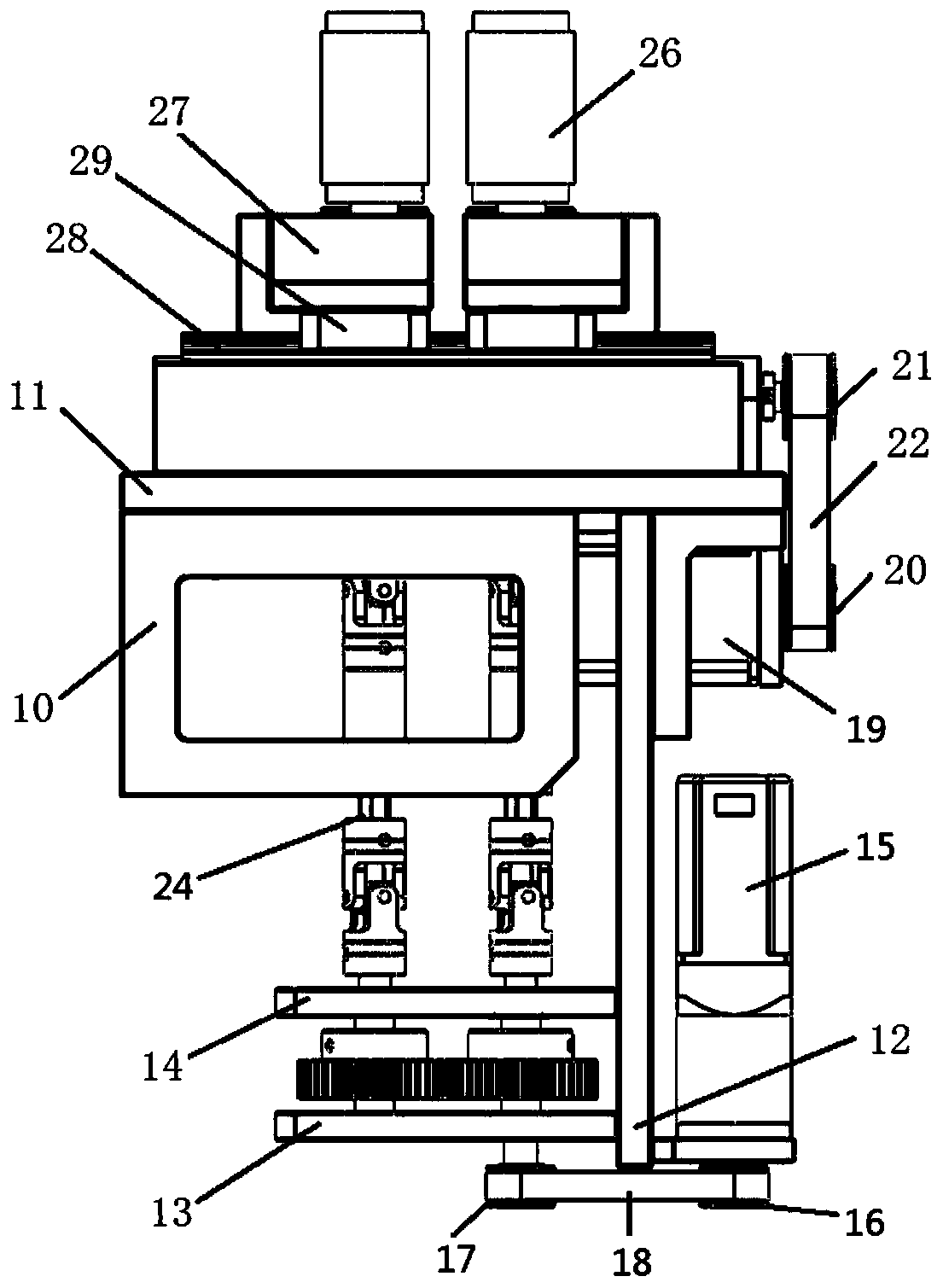

[0029] Such as Figure 1~8 As shown, a power lead wire stripping device includes a wire feeding device 1, a wire cutting device 2, and a wire stripping device 3 arranged in order from left to right. The wire cutting device 2 is arranged in the middle of the wire feeding device 1 and the wire stripping device 3.

[0030] The line transmission device 1 includes a line support plate 11, a line motor mounting plate 12, a first isolation plate 13, a second isolation plate 14, a line drive motor 15, a line ball screw 58, and a first driving pulley 16. , The first passive pulley 17, the first timing belt 18, the line ball screw 19, the second drive pulley 20, the second passive pulley 21, the second timing belt 18, the gear 23, the drive shaft 24, the drive roller 25, The fixed roller 26, the roller supporting seat 27, the vertical sliding groove seat 28, the sliding block 29, the screw nut s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com