Water chestnut peeling machine

A technology of peeling machine and water chestnut, which is applied in the peeling of vegetables or fruits, food science, application, etc. It can solve the problems of difficulty in peeling water chestnuts, low efficiency, and restrictions on the development of deep-processing products of water chestnuts, and achieve high peeling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

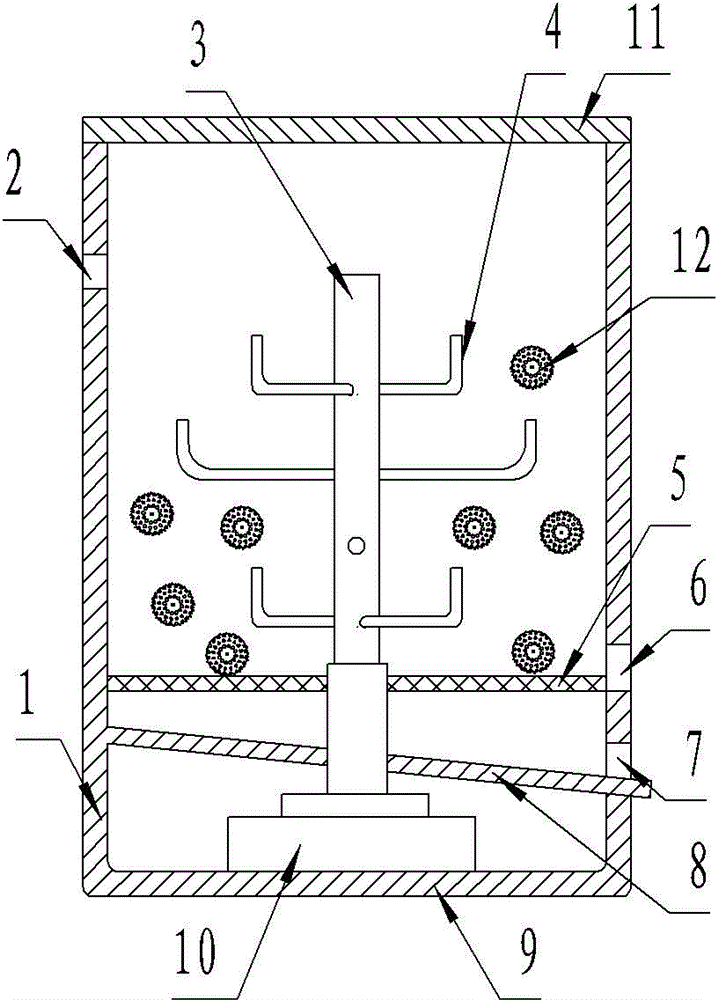

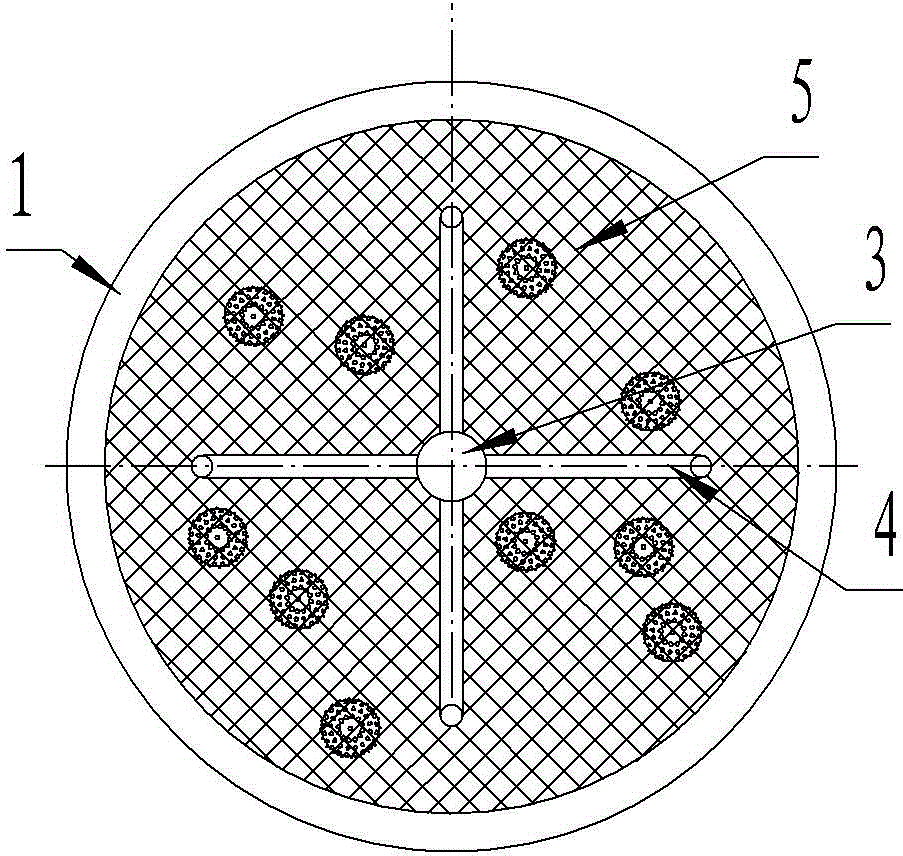

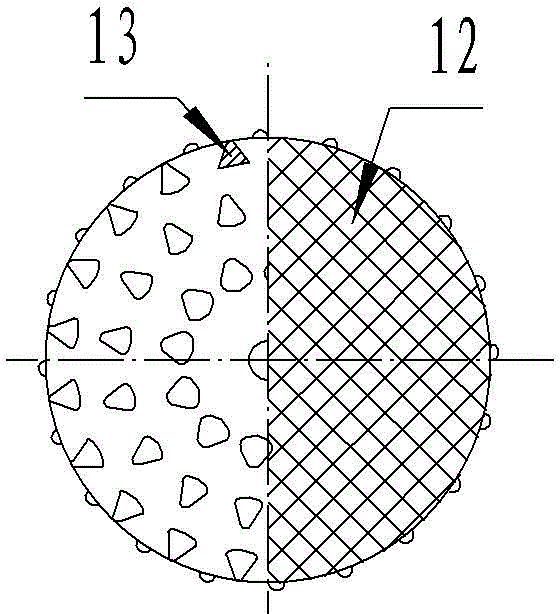

[0013] like figure 1 , figure 2 , image 3 The shown water chestnut peeling machine includes a barrel body 1, the barrel bottom of the barrel body 1 has two layers, and a horizontal motor 10 is provided between the upper layer barrel bottom 8 and the lower layer barrel body 9 in the barrel body. , the power output shaft of the horizontal motor 10 passes through the bottom 8 of the upper layer of the barrel, and is connected to drive a vertical shaft 3. The vertical shaft 3 is evenly provided with multiple rows of stirring rod groups, and each group of stirring rod groups includes at least four diameters. To the stirring rod 4 installed on the vertical shaft 3, the end of the stirring rod 4 is bent upwards to fully stir. The bottom of the lowermost group of stirring rods is provided with a screen 5 on the top of the barrel bottom 8 of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com