Tree barking device

A technology for peeling skins and trees, which is applied in the field of agricultural machinery, and can solve problems such as inability to meet production requirements, slow device updates, and singleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

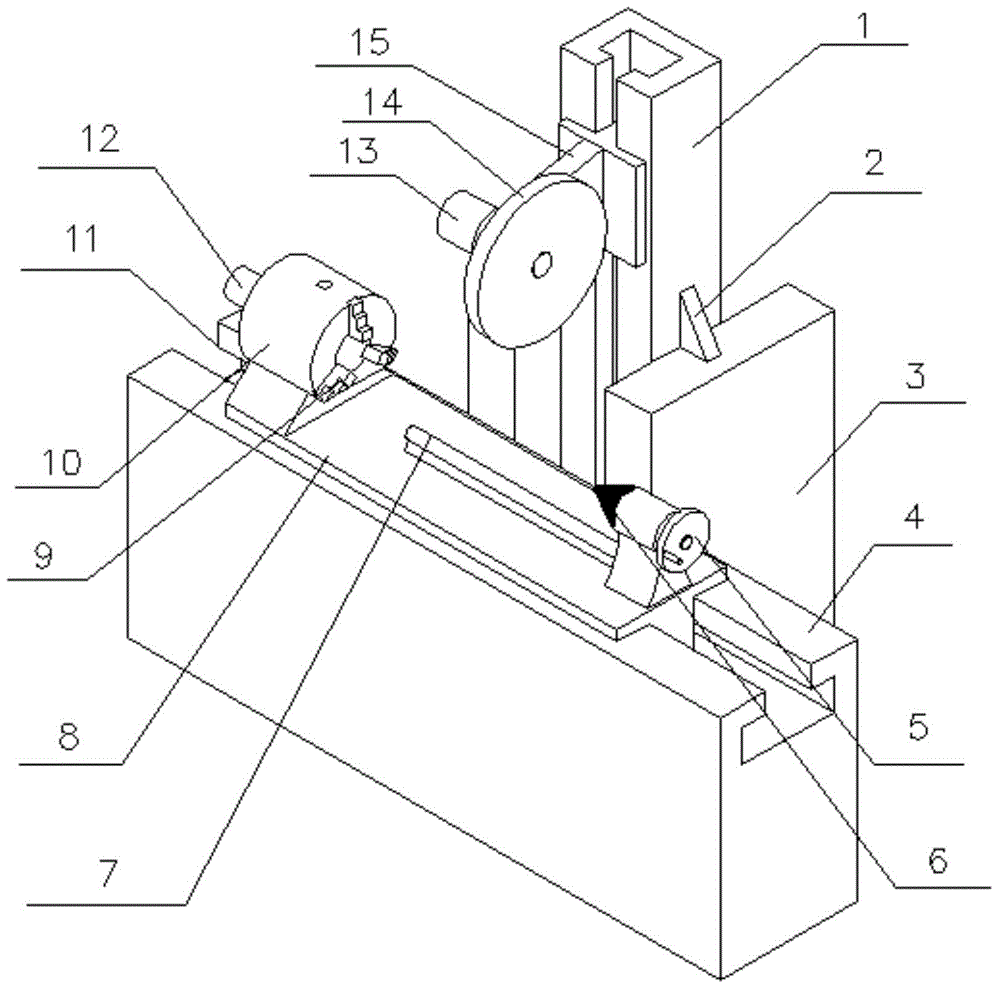

[0008] A tree barking device is composed of a grinding wheel guide rail 1, a reinforcing rib 2, a grinding wheel guide rail support seat 3, a mechanism main body 4, a turntable 5, a top 6, a tailstock guide rail 7, a workbench 8, an angle iron clamp 9, and a chuck 10 , Workbench guide rail 11, spindle motor 12, grinding wheel motor 13, grinding wheel 14, grinding wheel frame 15, grinding wheel guide rail 1 and grinding wheel guide rail support seat 3 are fixedly connected together, and reinforcing ribs 2 are located at grinding wheel guide rail 1 and grinding wheel guide rail support seat 3 Between them, distributed on both sides of the grinding wheel guide rail 1, the grinding wheel guide rail support seat 3 is fixedly connected with the mechanism main body 4, the workbench guide rail 11 is installed on the mechanism main body 4, the workbench 8 is installed on the workbench guide rail 11, and the tailstock guide rail 7 is fixed on the workbench 8, the top 6 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com