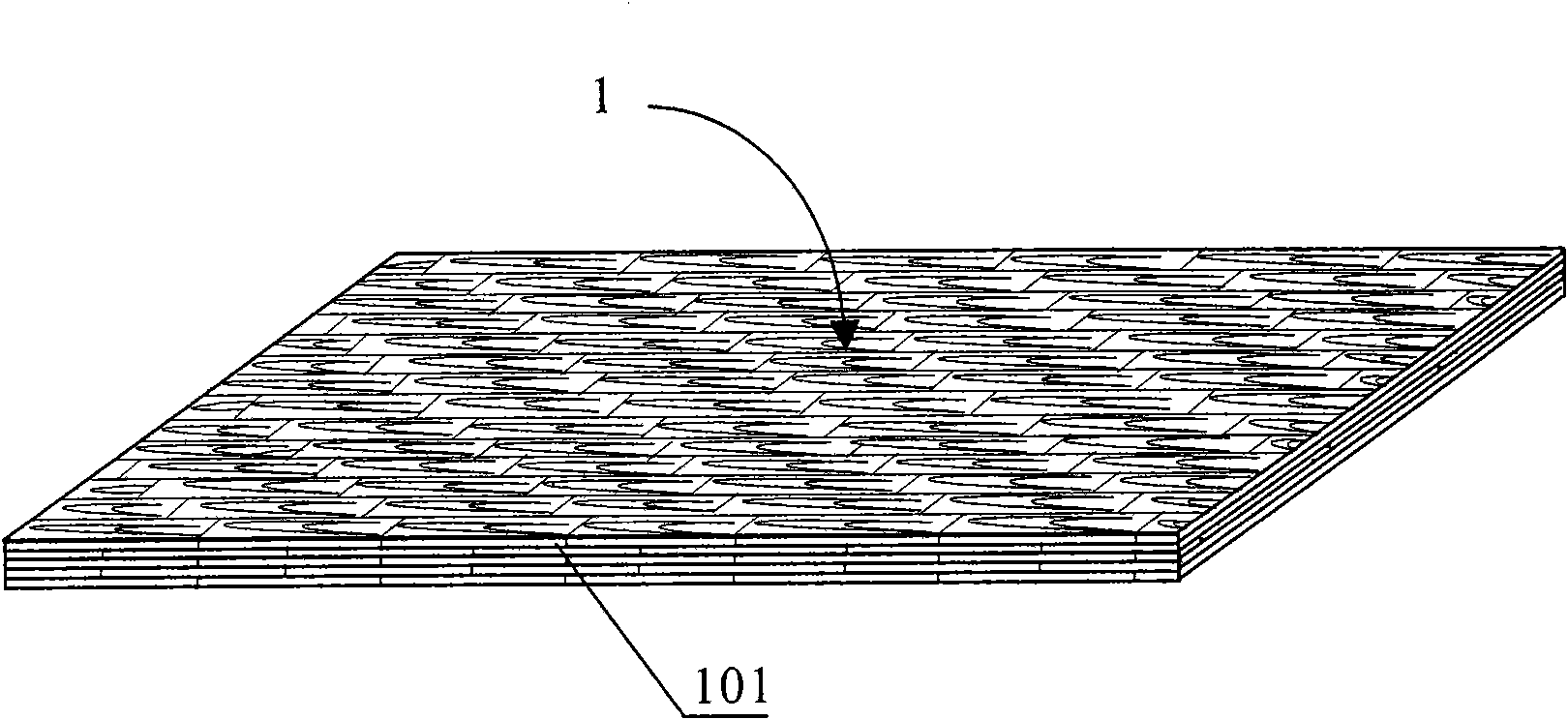

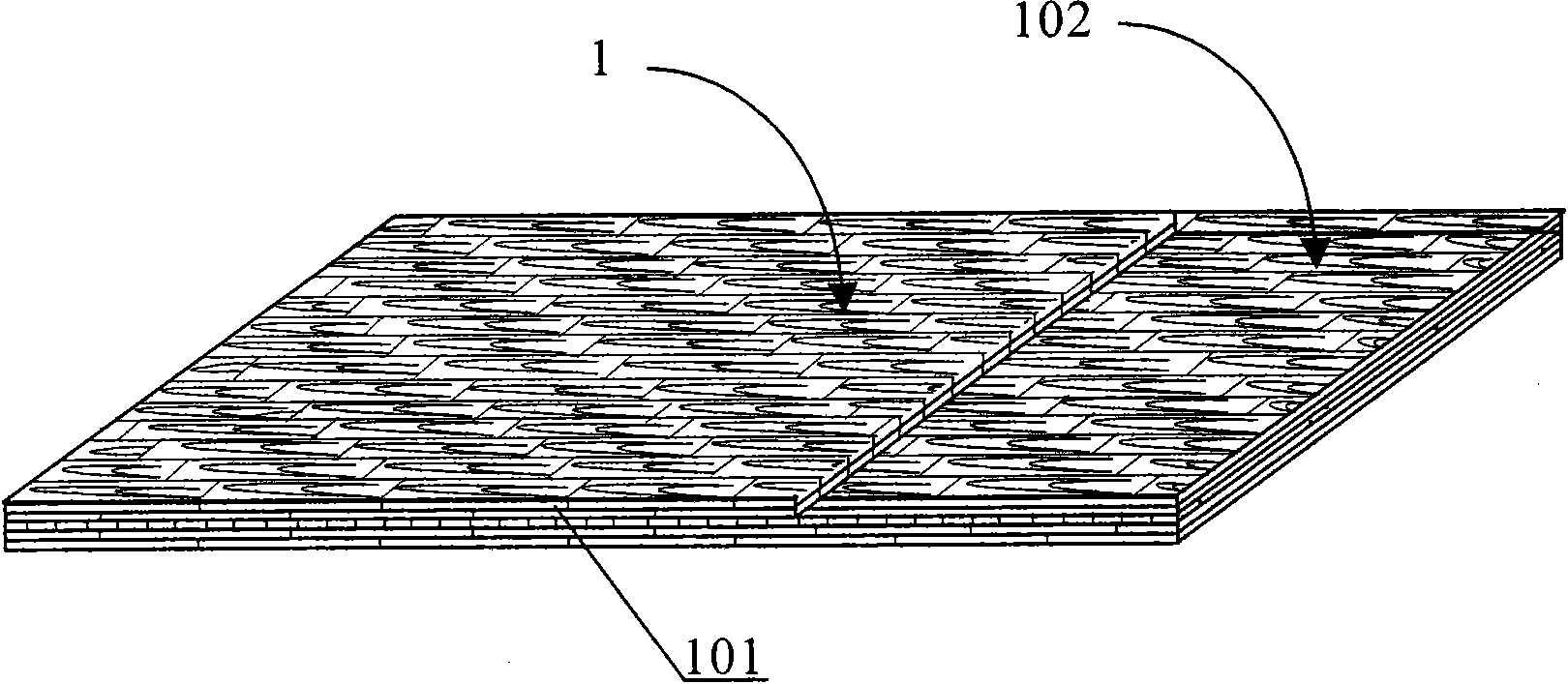

High-performance wood restructuring laminated wood and manufacturing method thereof

A manufacturing method and high-performance technology, applied in the field of wood processing, can solve the problems of complicated processing technology, damaged wood structure, and reduced product performance, and achieve the effect of good decorative performance, strong wood feeling and product quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

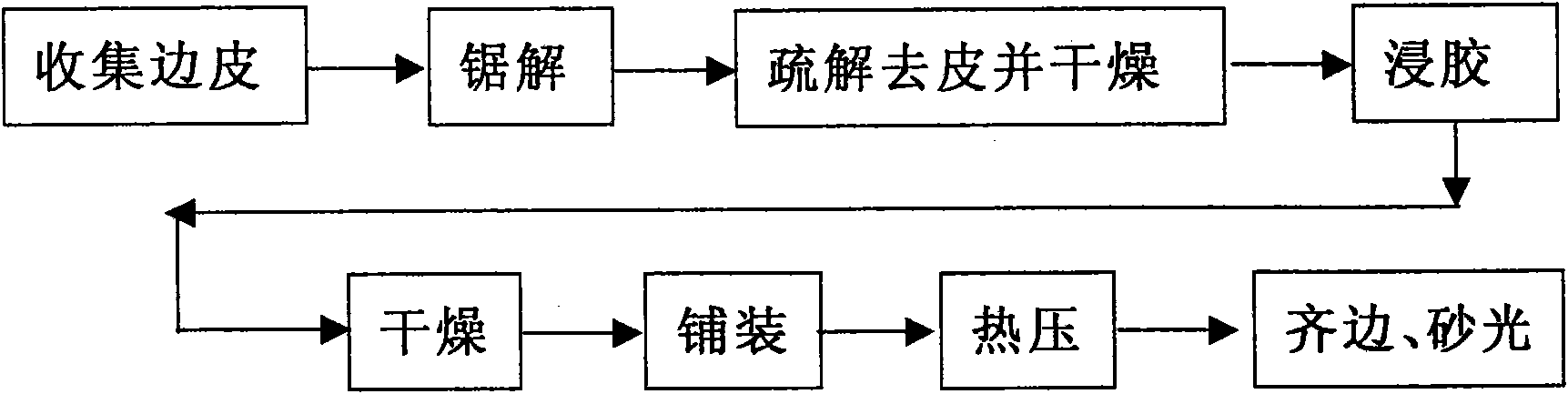

Embodiment 1

[0050] First select the residue in the sawing process of Chinese fir wood - fir bark as a raw material, and saw it into side strips with a width of 5-20mm and a length of 10-50cm. Then, the fir edge strips with bark are rolled and loosened to separate the bark from the wood edge strips, and put into a drying oven to dry the edge strips to a moisture content of 6%-12%. The third step is to immerse the dried wood edge strips in the modified phenolic resin glue with a solid content of 20%. %the following. The fourth step is to evenly spread the dipped and dried wood edge strips in a concave groove to form a slab, and then push the blank into a mold placed on a hot press for hot pressing, and press according to the following hot pressing process parameters : Hot-pressing temperature 120-160°C; hot-pressing pressure 2-7MPa (adjusted according to the density of the product); hot-pressing time, 1-3 minutes per mm plate thickness, that is, 1-3min / mm, to form a square material. After...

Embodiment 2

[0052] Select the discarded broken veneers produced in the production of plywood, remove the broken veneers with a length less than 5cm, and cut the veneer strips with a length greater than 50cm and a width greater than 20mm into side strips with a width of 5-20mm and a length of 10-50cm. Then, according to the production conditions of Example 1, the selected edge strips are dipped, dried, paved, hot-pressed and finished to form a finished board and square material. If the density is 0.8g / cm 3 1. For a plate with a thickness of 20mm, the elastic modulus is 24730MPa, the static bending strength is 121MPa, and the boiling internal bonding strength is 0.35MPa.

Embodiment 3

[0054] The sawed slats produced in the production of finger-jointed integrated boards are selected without other treatment, and the finished boards and squares are formed by dipping, drying, paving, hot pressing and post-finishing directly according to the production conditions of Example 1 . If the density is 1.0g / cm 3 1. A plate with a thickness of 25mm has an elastic modulus of 28650MPa and a static bending strength of 167MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com