Slitting and bamboo joint removing integrated machine for bamboo billet cylinder

An external cylinder, solid technology, applied in mechanical equipment, sugarcane machining, bark, etc., can solve the problems of backwardness and low work efficiency, and achieve the effect of simple operation, high production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

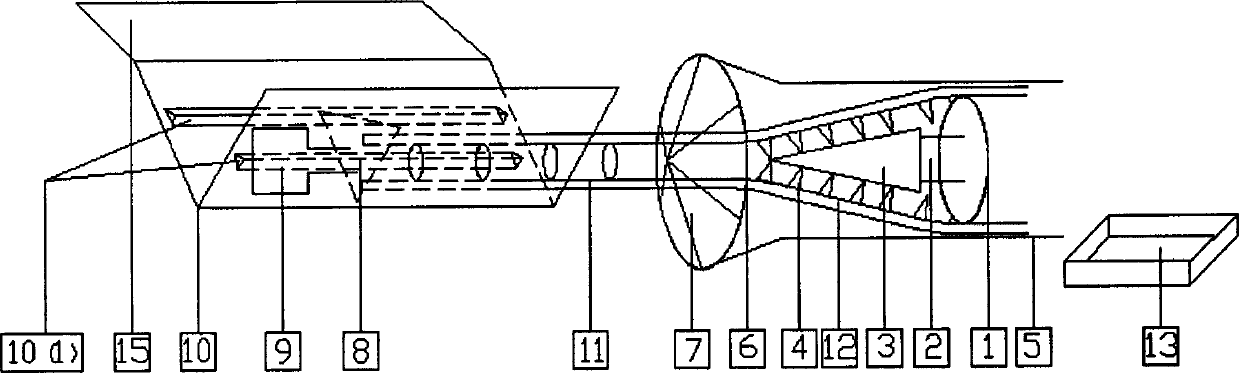

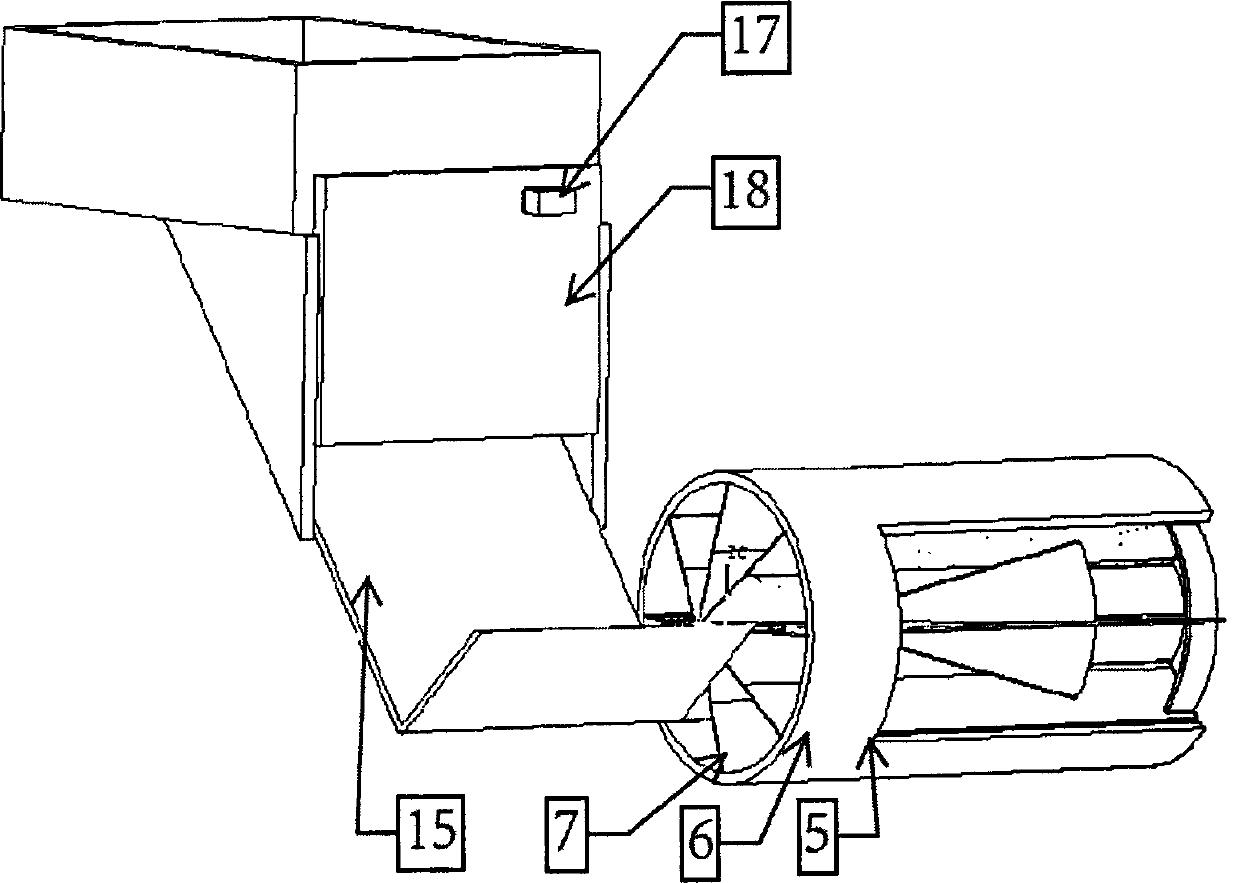

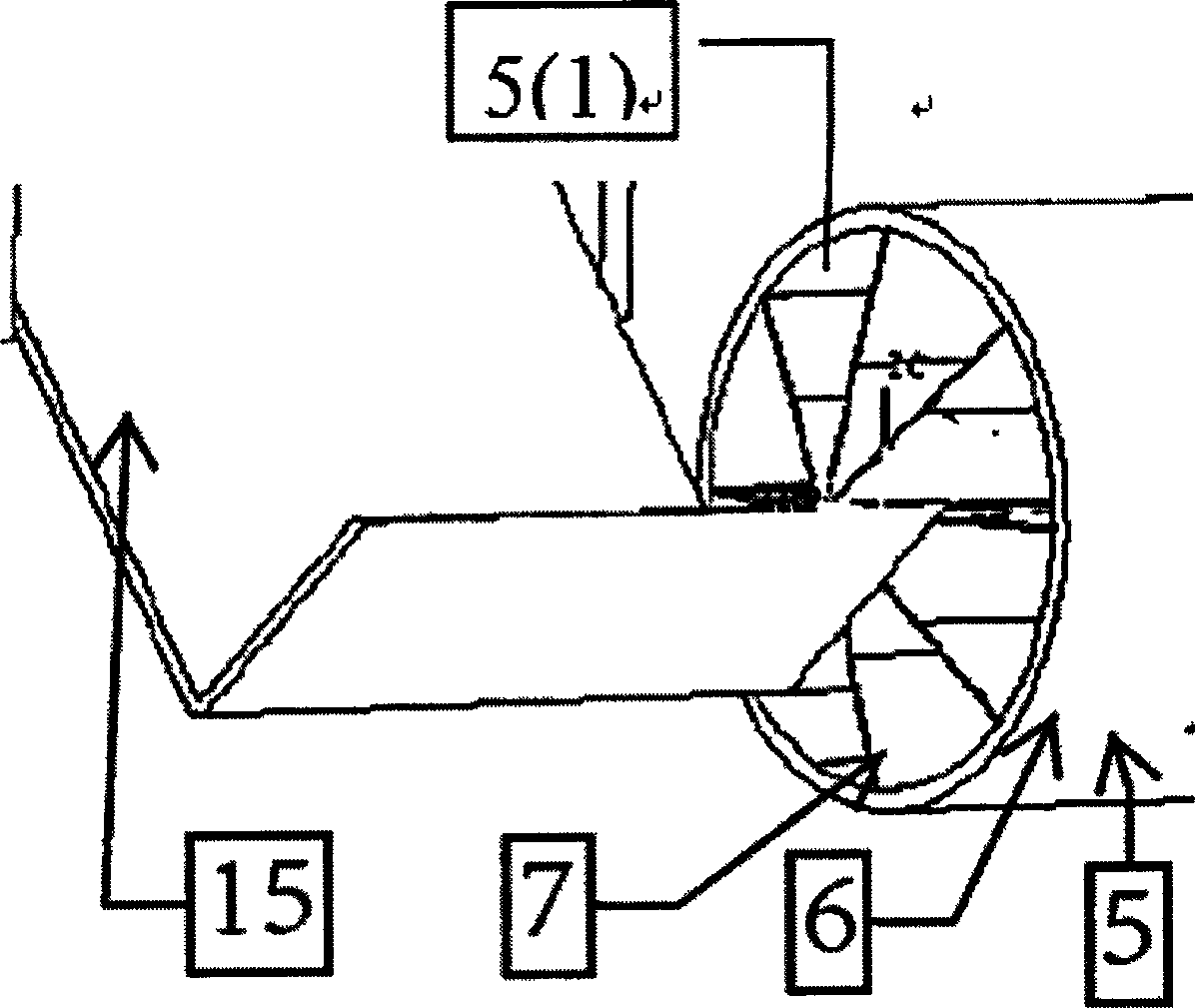

[0014] as attached figure 1 As shown, the bamboo blank tube knuckle removing machine described in the patent of the present invention includes a feeding device, a fixing device, a propulsion device, a strip opening device, a knuckle removing device and a receiving device.

[0015] as attached figure 1 , attached figure 2 And attached image 3 As shown, the movable baffle 8 is reciprocated on the fixture 10 by the fixed guide rail 10 (1), the power unit 9 is connected with the right end of the movable baffle 8, and the left end of the movable baffle 8 is in contact with the right end of the bamboo tube 11 to be processed. , the cutting knife 7 is connected with the annular cutterhead 6, and is evenly distributed on the annular cutterhead 6 in a conical shape, the annular cutterhead 6 is connected with the outer cylinder 5, the outer cylinder 5 and the solid cone 3 are connected through the inner sheet 14 of the outer cylinder, and the solid The cone 3 is connected to the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com