Treatment process for improving comprehensive properties by alloying surface of sucker rod

A technology of surface alloying and comprehensive performance, applied in metal material coating process, heat treatment furnace, heat treatment equipment, etc., can solve the problems of sucker rod corrosion and fracture, pile up of scrap rods, shortened service life, etc., and achieve economic benefits Considerable, outstanding innovation, improved thermal hardness and high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

[0018] A high-comprehensive-performance modification treatment process for the surface alloying of sucker rods, the specific steps of which are as follows:

[0019] 1. The surface of the sucker rod workpiece is treated by sandblasting, derusting and pickling, so that the surface is oil-free and rust-free;

[0020] 2. Calculated according to the weight percentage, take 95% chromium powder, 1% ammonium chloride and 4% ferric chloride, make a paste with hydrolyzed ethyl silicate, and coat it on the surface of the workpiece with a coating thickness of 0.25mm; after drying , under argon protection, high-frequency current induction heating to 1200 ° C, heat preservation for 2 minutes;

[0021] 3. Pre-cool the sucker rod to 820°C for quenching and water cooling;

[0022] 4. Heat to 180°C, temper for 2.5 hours, and air cool to room temperature.

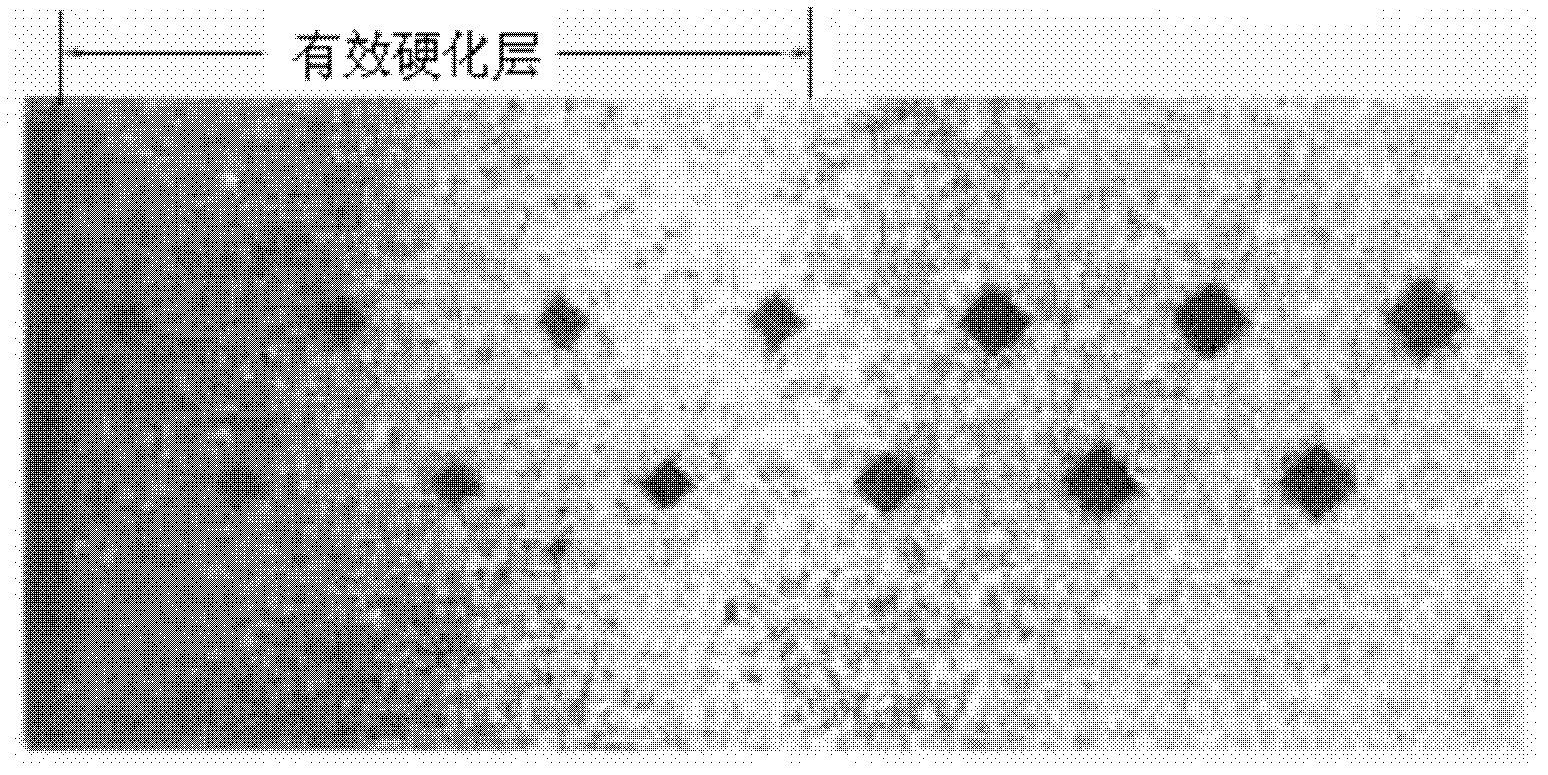

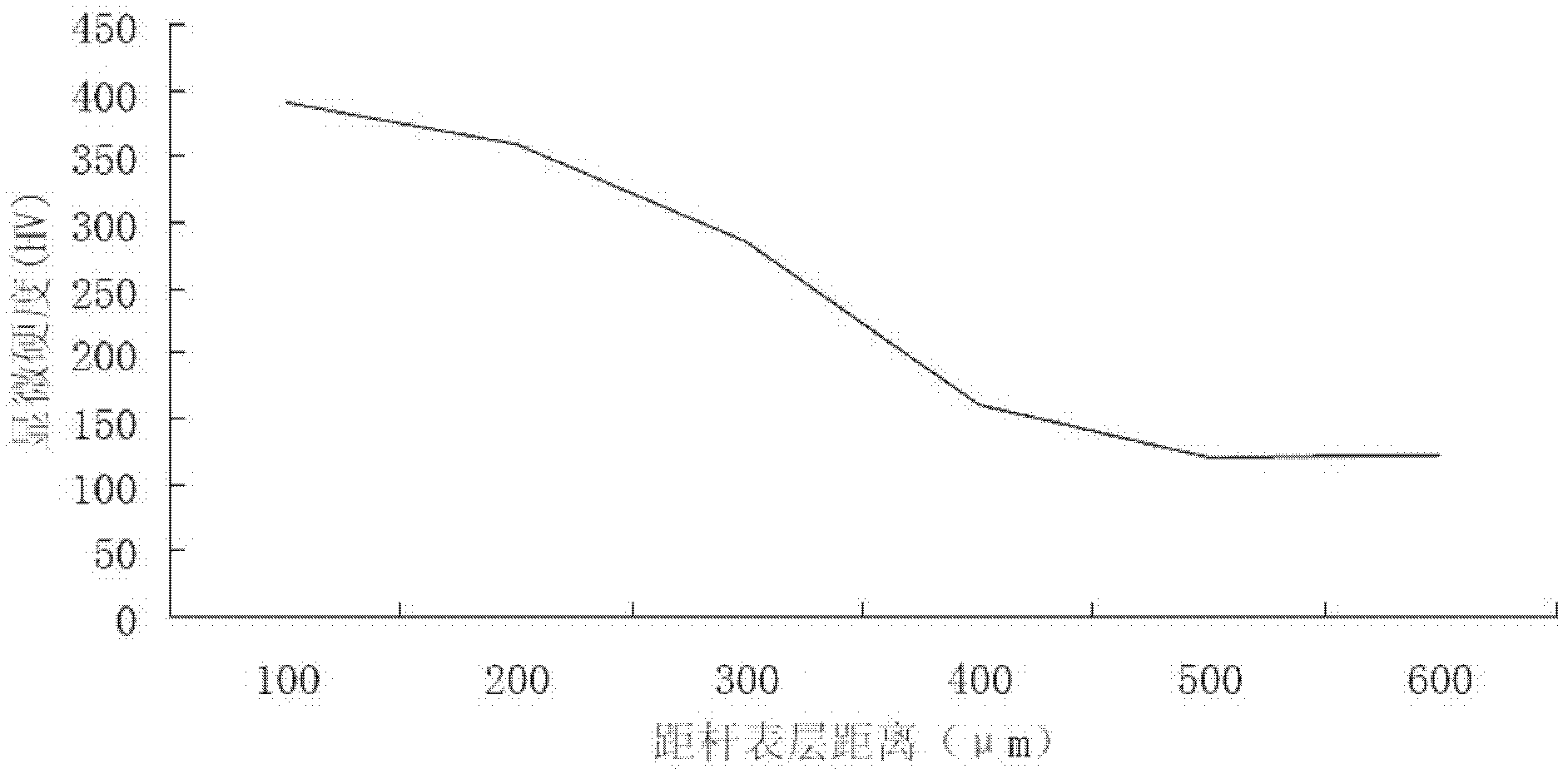

[0023] The structure of the suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com