High-performance electromagnetic shielding composite paper-based material as well as preparation method and application thereof

An electromagnetic shielding and composite paper technology, applied in the fields of magnetic field/electric field shielding, synthetic cellulose/non-cellulose material pulp/paper, papermaking, etc. Market prospects and economic value, the effect of improving interface properties and mechanical properties, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

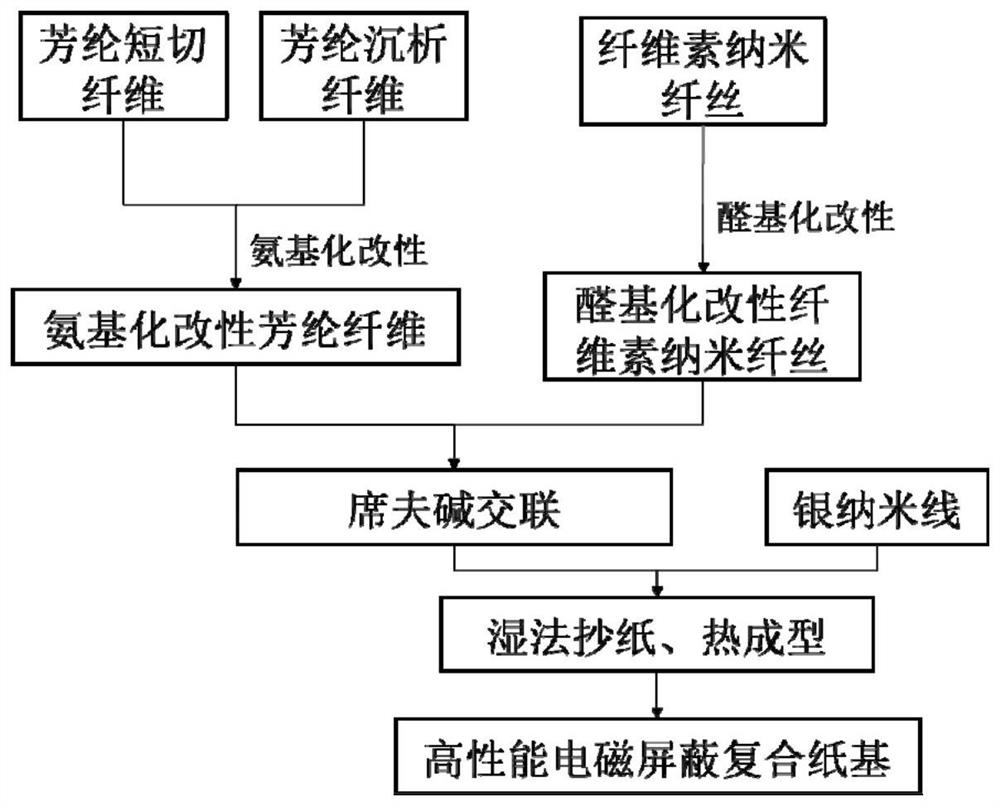

Method used

Image

Examples

Embodiment 1

[0031] A high-performance electromagnetic shielding composite paper-based material, the preparation method of which is as follows:

[0032](1) Surface modification of aramid fibers: aramid precipitated fibers and aramid chopped fibers (purchased from a domestic fiber material technology Co., Ltd.) are mixed evenly according to the mass ratio of 9:1, and then put into a solution with a pH of 8.5. Tris-hydrochloric acid buffer solution (Tris-HCl buffer solution), wherein, the ratio mass of aramid fiber (that is, the total mass of aramid precipitated fiber and aramid chopped fiber) to Tris-HCl buffer solution ( g): volume (ml) = 1:50, add dopamine as an amino modifier, and its final concentration is 0.01g / L; the temperature of the modification reaction is 20°C, and the nitrogen protection with a flow rate of 30ml / min, the processing time After 48 hours, filter with suction to collect the modified aminated aramid fiber (aminated aramid fiber) for later use.

[0033] (2) Surface m...

Embodiment 2

[0037] A high-performance electromagnetic shielding composite paper-based material, the preparation method of which is as follows:

[0038] (1) Surface modification of aramid fiber: aramid precipitated fiber and aramid chopped fiber (purchased from a domestic fiber material technology Co., Ltd.) are mixed evenly according to the mass ratio of 3:7, and then put into the pH of 8.5 Tris-hydrochloric acid buffer solution (Tris-HCl buffer solution), wherein, the ratio mass of aramid fiber (that is, the total mass of aramid precipitated fiber and aramid chopped fiber) to Tris-HCl buffer solution ( g): volume (ml) = 1:50; dopamine is added as an amino modifier, and its final concentration is 0.01g / L; the temperature of the modification reaction is 50°C, and the nitrogen protection with a flow rate of 30ml / min is used. After 8 hours, filter with suction to collect the modified aminated aramid fiber (aminated aramid fiber) for later use.

[0039] (2) Surface modification of cellulose ...

Embodiment 3

[0043] A high-performance electromagnetic shielding composite paper-based material, the preparation method of which is as follows:

[0044] (1) Surface modification of aramid fiber: aramid precipitated fiber and aramid chopped fiber (purchased from a domestic fiber material technology Co., Ltd.) are mixed evenly according to the mass ratio of 6:4, and then put into the pH of 8.5 Tris-hydrochloric acid buffer solution (Tris-HCl buffer solution), wherein, the ratio mass of aramid fiber (that is, the total mass of aramid precipitated fiber and aramid chopped fiber) to Tris-HCl buffer solution ( g): volume (ml) = 1:50; add L-3,4-dihydroxyphenylalanine as an amino modifier, and its final concentration is 0.01g / L; the temperature of the modification reaction is 50°C, use Nitrogen protection at a flow rate of 30ml / min, the treatment time is 12h, suction filtration, and the modified aminated aramid fiber (aminated aramid fiber) is collected for future use.

[0045] (2) Surface modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com