Device and method for ore-crushing with recycling

A technology of ore and equipment, applied in the direction of application, cocoa, grain processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

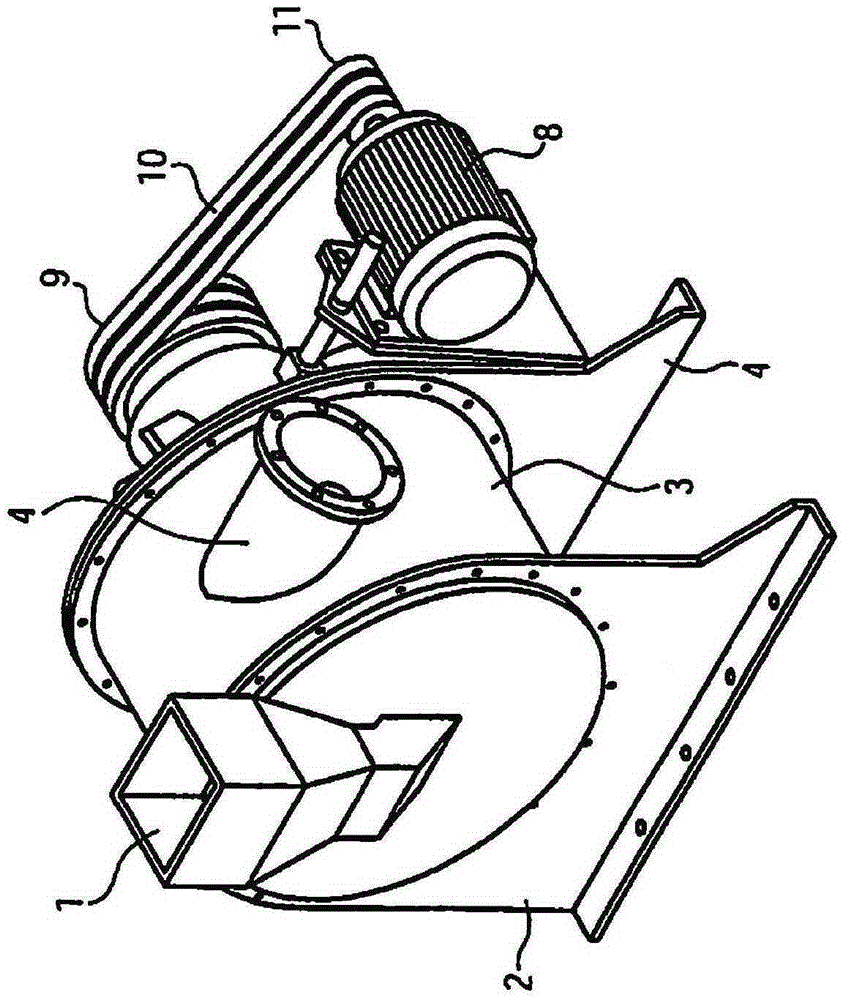

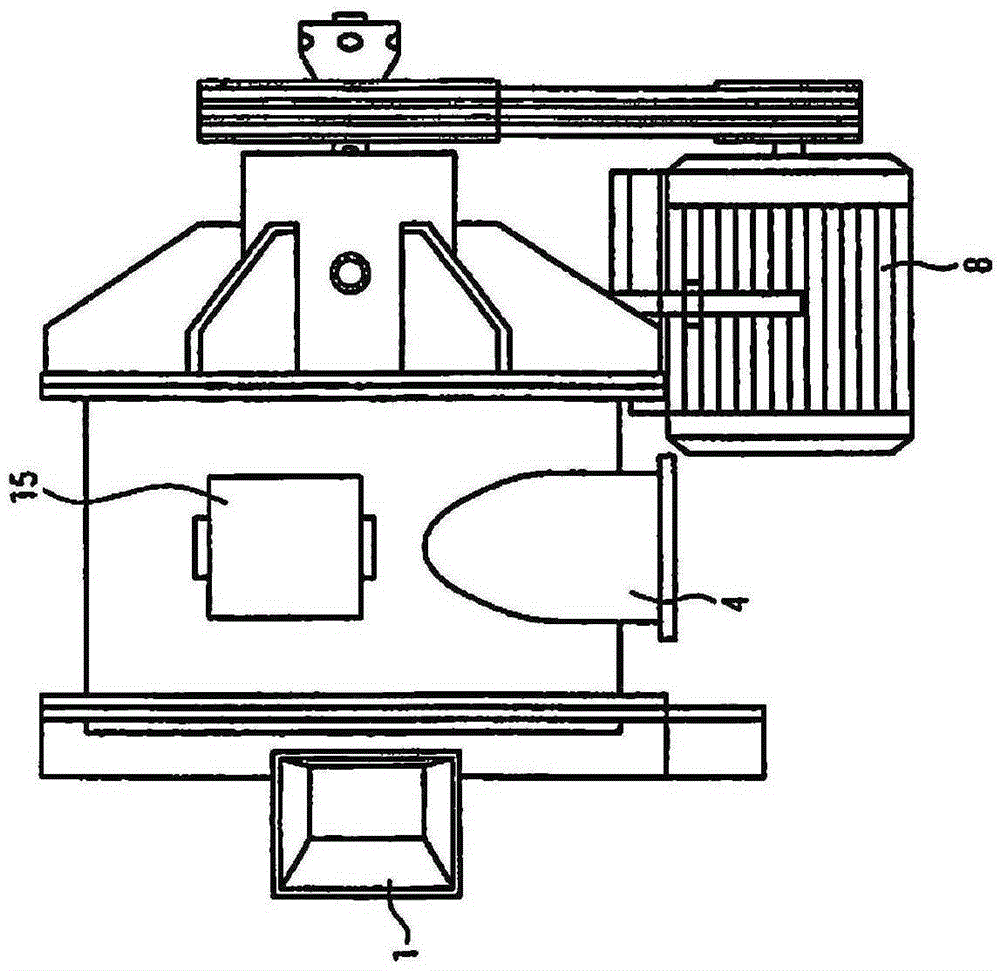

[0099] according to figure 1 , shows the apparatus according to the invention, the ore to be crushed and the slag to be crushed are respectively introduced into a funnel or a supply hopper 1, which constitutes an ore supply unit. Alternatively, instead of the hopper, a screw conveyor can also be provided, which feeds the ore to be crushed under pressure into the first crushing device. Ore is fed through a hopper 1 to a cylindrical housing 3 mounted on one foot 2 and one foot 6 . The grinding of the ore to be crushed takes place in this housing 3 . Here, the motor 8 transmits torque from the motor 8 to the pulverizer via the drive roller 11 and the belt 10 and pulley 9 .

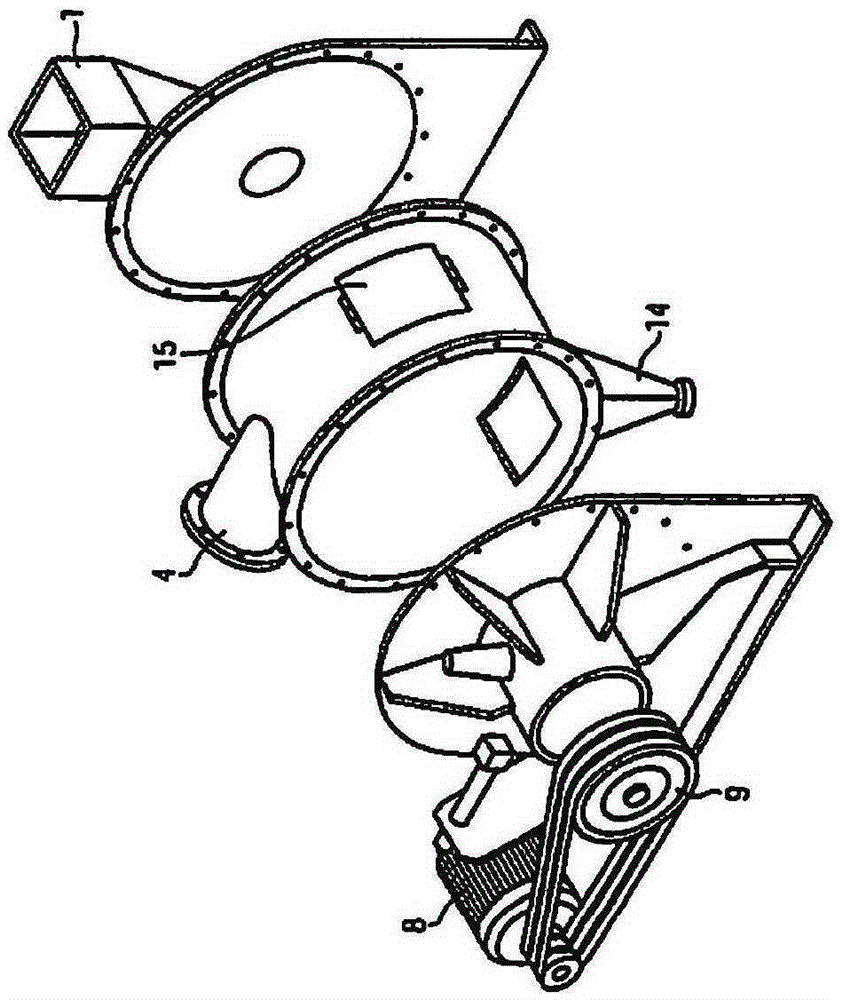

[0100] as specifically available from figure 2 As a consequence, a suction opening 4 is optionally possible, through which the ground ore can be drawn off by means of negative pressure. Alternatively, in particular generally, an outlet funnel 14 is provided in the lower region of the housing 3 , which ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com