Solid-liquid separation device and method for producing Hopcalite

A technology of solid-liquid separation and gas-liquid separator, which is applied in the direction of separation methods, filtration separation, chemical instruments and methods, etc. It can solve the problems of non-recyclable, large amount of soda ash used, and low production efficiency, so as to avoid waste and improve production efficiency. The effect of high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

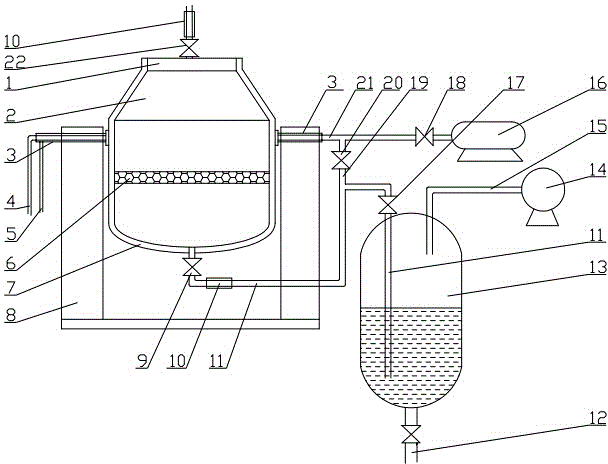

[0044] A solid-liquid separation device, see figure 1Shown, comprise airtight tank 2, air compressor 16, vacuum pump 14 and gas-liquid separator 13; The outer side of the airtight tank 2 is provided with a rotating shaft 3, and the rotating shaft 3 is connected with the power turning device of the airtight tank 2; the rotating shaft 3 is a hollow shaft, and the upper part of the filter layer 6 inside the airtight tank 2 is connected with the air compressor 16 through the rotating shaft 3 and the air pressure pipeline 21; The bottom of the airtight tank 2 is provided with a drain valve 9 and a drain pipeline 11, the other end of the drain pipeline 11 is connected to a gas-liquid separator 13, and the top of the gas-liquid separator 13 is connected to a vacuum pump 14 through a vacuum pipeline 15, and the gas-liquid separator 13 The bottom is provided with a discharge port 12; the air pressure pipeline 21 and the discharge pipeline 11 are connected by a pipeline 19, and the pip...

Embodiment 2

[0067] Solid-liquid separation device is with embodiment 1, and the difference of the method for producing hopcalate agent and embodiment 1 is:

[0068] The applied pressure in step 2) and step 4) is: applied positive pressure 2MPa, applied negative pressure -0.1MPa.

[0069] Step 5): The amount of water added to the airtight tank 2 is 10 times the mass of the solid material in the airtight tank 2 in step 6).

[0070] Step 6): After repeating the washing operation of step 5) once, a damp semi-finished product of hopcalate agent is obtained.

[0071] Step 7): In the water removal step, the heating temperature of the airtight tank 2 is 60°C.

Embodiment 3

[0073] Solid-liquid separation device is with embodiment 1, and the difference of the method for producing hopcalate agent and embodiment 1 is:

[0074] The applied pressure in step 2) and step 4) is: applied positive pressure 0.1MPa, applied negative pressure -0.1MPa.

[0075] Step 5): The amount of water added to the airtight tank 2 is 0.5 times the mass of the solid material in the airtight tank 2 in step 6).

[0076] Step 6): After repeating the step 5) washing operation for 3 times, a damp semi-finished product of hopcalate agent is obtained.

[0077] Step 7): In the water removal step, the heating temperature of the airtight tank 2 is 120°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com