Environment-friendly garbage smashing device

A garbage crushing and environmental protection technology, applied in the field of environmental science and technology, can solve the problems of poor crushing effect and adverse effects on health, and achieve good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

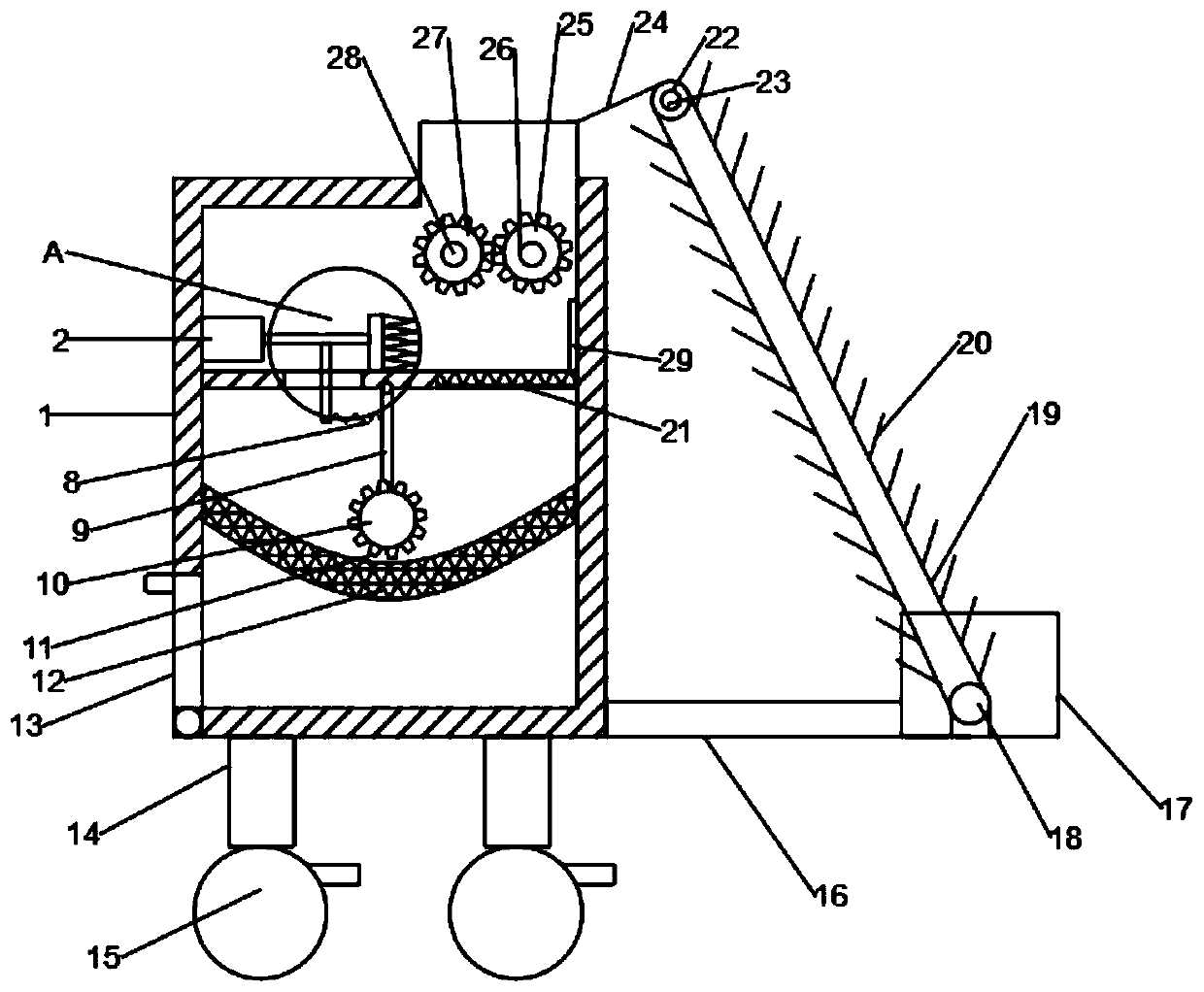

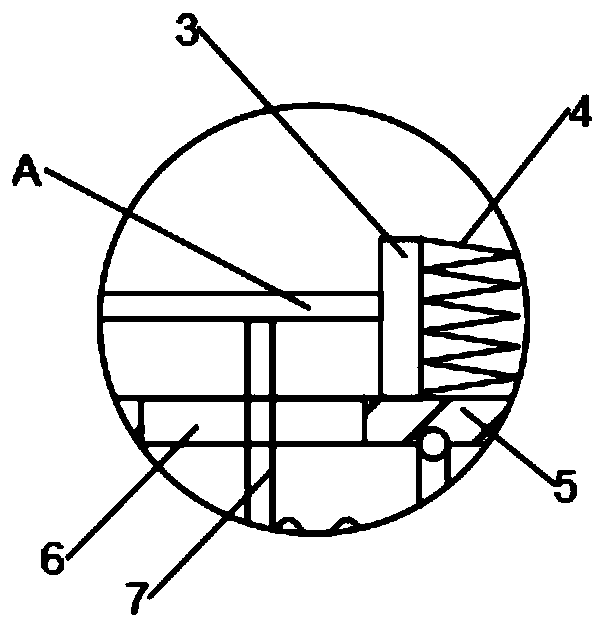

[0021] see Figure 1~2 , in the embodiment of the present invention, a garbage crushing device for environmental protection includes a device main body 1, a hydraulic cylinder 2, a first filter plate 12, a storage box 17, a feeding conveyor belt 19 and a second motor 26, the device main body 1 is provided with a feeding box on the right side of the top, the upper end of the right side of the feeding box is connected with the driving wheel 22 through the slide plate 24, the driving wheel 22 is arranged on the first motor 23, and the driving wheel 22 is connected to the driven wheel 18 through the feeding conveyor belt 19 Link to each other, while the feeding conveyor belt 19 is provided with some feeding plates 20, the value of the included angle between the feeding plate 20 and the vertical direction is 30-45 degrees, the driven wheel 18 is arranged on the bottom of the storage box 17, and is connected with the support rod rotation, The support rod is used to support the drive...

Embodiment 2

[0028]An environment-friendly garbage processing equipment includes the environment-friendly garbage crushing device described in Embodiment 1.

[0029] The working principle of the present invention is: the driven wheel 18 is arranged on the bottom of the storage box 17, and is connected in rotation with the support rod, and the support rod is used to support the driven wheel 18, while the lower end of the support rod is fixed to the bottom inner surface of the storage box 17 Connected, the storage box 17 is fixedly connected with the device main body 1 through the connecting plate 16, the storage box 17 is used to store garbage, and solves the problem that people are easily injured due to excessive garbage, and the second crushing roller 27 is arranged at the front end of the rotating rod 28 , through the mutual cooperation of the second motor 26 and the second crushing roller 27, the crushing of the rubbish is realized. The rotating rod 28 is rotationally connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com