Floatable driving plate and grain pulling chain combined roller plate type corncob breaking-off mechanism

A combined, reel chain technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as easy gnawing of corn ears, simplifies the transmission mode, solves corn damage, and is conducive to comprehensive recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the embodiments given by the accompanying drawings.

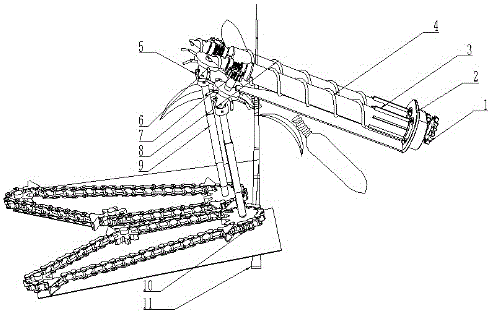

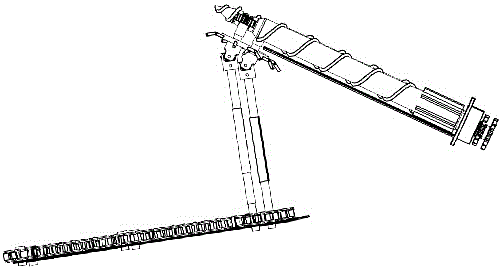

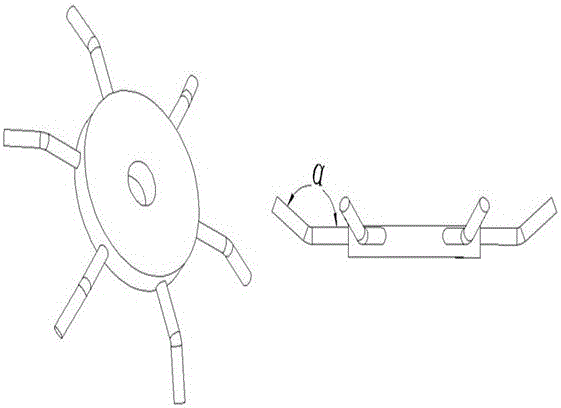

[0014] refer to figure 1 , figure 2 , a floating reel chain combined roller plate corn ear breaking mechanism, including a transmission gear (1), a box (2), an ear retaining plate (3), a short conveying stem roller (4), and a universal joint (5), reel (6), worm gear (7), long conveying stem roller (8), floating rod (9), reel chain (10), it is characterized in that: described a kind of can float The dial chain combined roller plate type corn ear breaking mechanism includes a pair of long conveying stalk pulling rollers (8), short conveying stalk pulling rollers (4) and short conveying stalk pulling rollers (4), long conveying stalk pulling rollers ( 8) A pair of fringe retaining plates (3) and a pair of reels (6) at the bottom are respectively located at the front ends of the long conveying stalk roller (8) and the short conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com