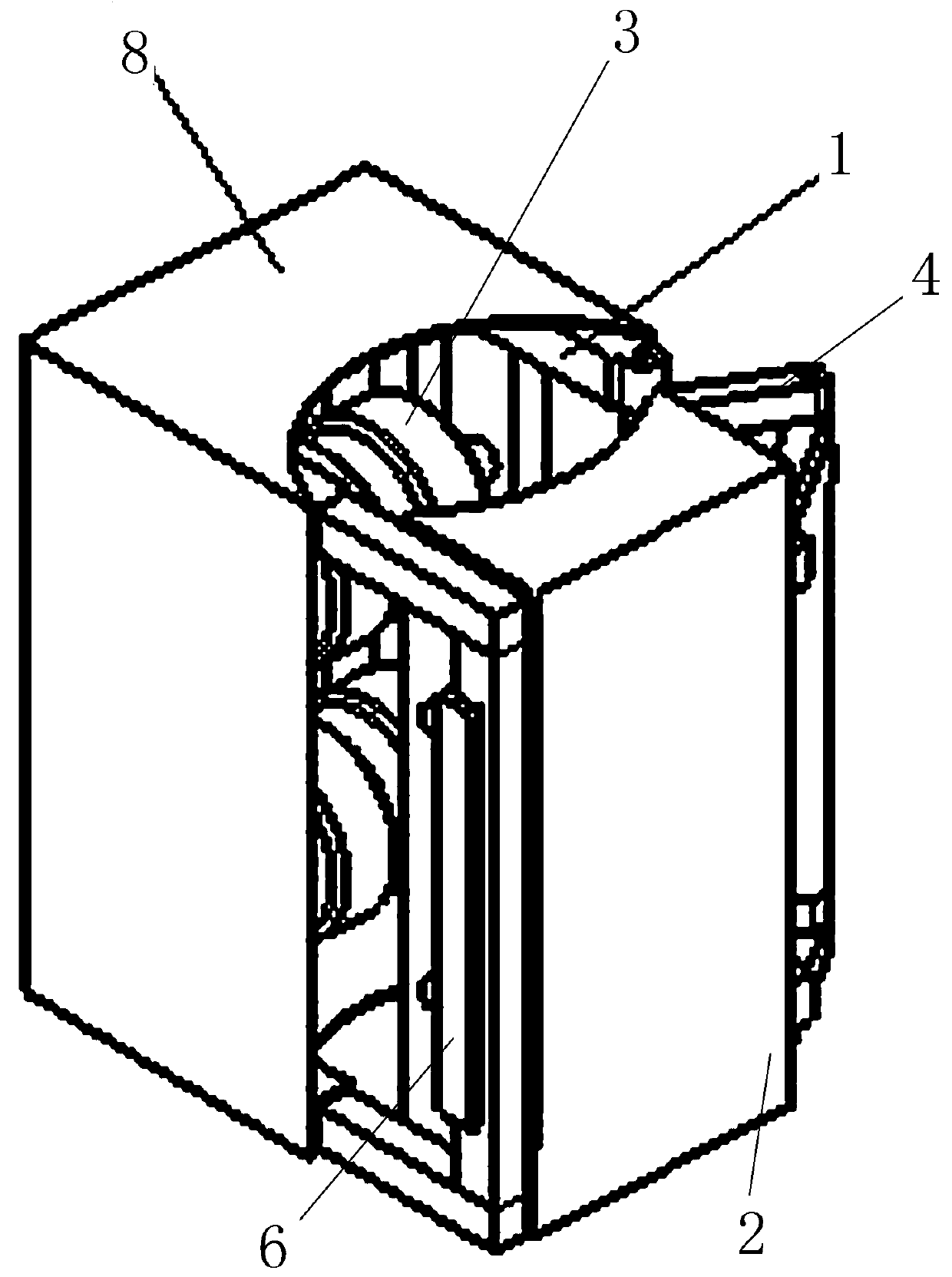

Pole-climbing robot

A robot and pole-climbing technology, which is applied in the field of pole-climbing robots, can solve problems such as potential safety hazards, inability to use for a long time, robot falling, etc., and achieve the effect of simple and convenient adjustment process, safe and reliable power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0048] Embodiment 2: The arrangement of the upper and lower rows of the traveling wheel mechanism in this embodiment, each row having two rubber-coated wheels arranged at intervals, is the same as that of the traveling wheel mechanism in Embodiment 1, the difference is that: The structural form of the frame, the structure and arrangement of the telescopic mechanism, and the structure and arrangement of other auxiliary components are all different, and may be common forms in the prior art.

Embodiment 3

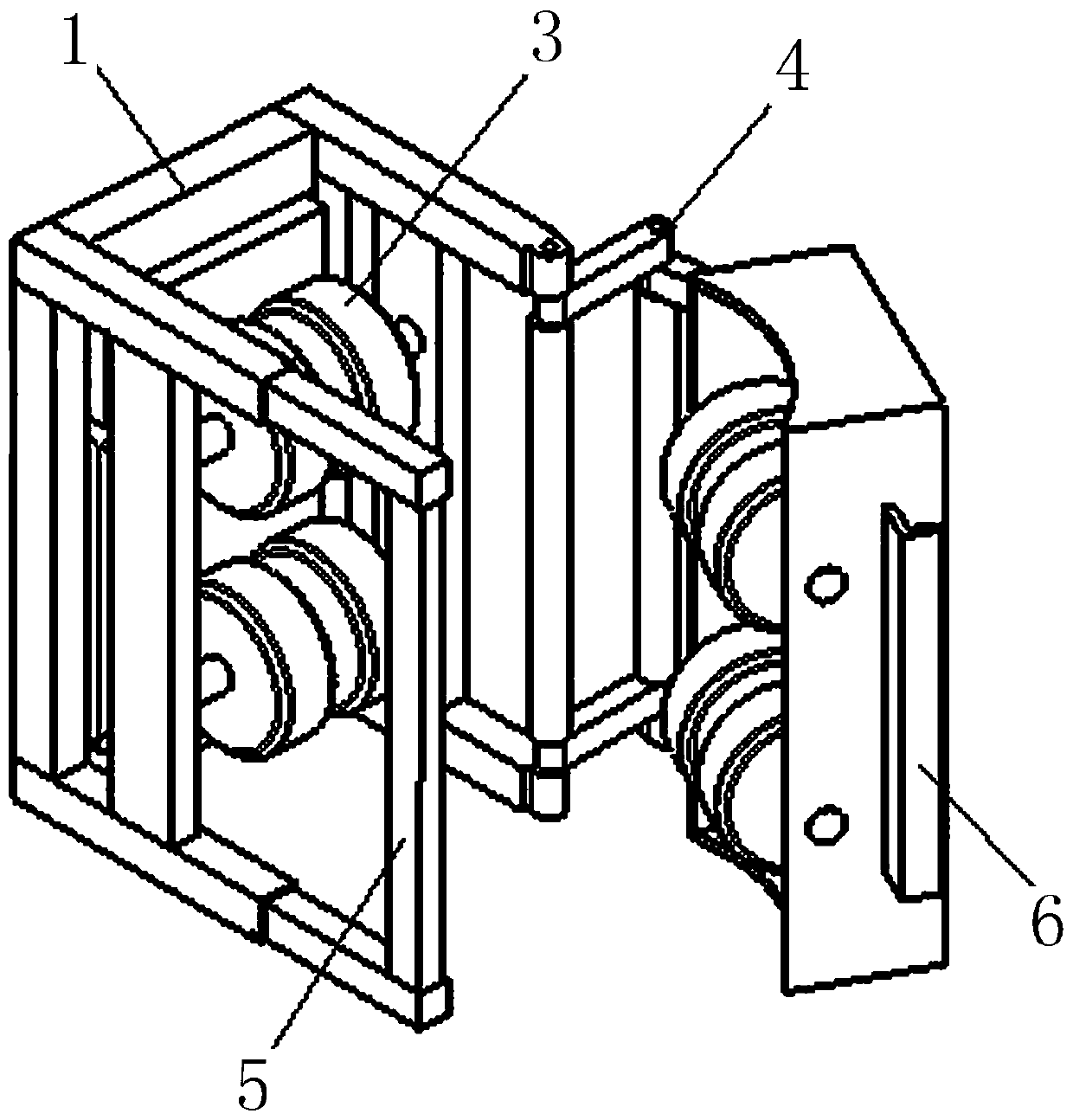

[0049] Embodiment 3: as Figure 6-8 As shown, the difference from Embodiment 1 is that both sides of the structure of the two frames are provided with telescopic mechanisms, and one end of the telescopic mechanism on one side is rigidly connected to the second frame, and the other end is passed through the hinge 30 (ie, the hinge). Flexible connection with the first frame; one end of the telescopic mechanism on the other side is rigidly connected with the first frame, and the other end is connected with the buckle structure of the second frame through an openable buckle structure, that is, U-shaped movable hook 5 and fixed hook 6 , the two telescopic mechanisms are respectively rigidly connected with the first frame and the second frame to form an L-shaped frame, and the two L-shaped frames face each other to form a rectangular frame, and a joint of the two L-shaped frames is connected by the hinge 30 The other connection is a detachable connection formed by the movable hook 5...

Embodiment 4

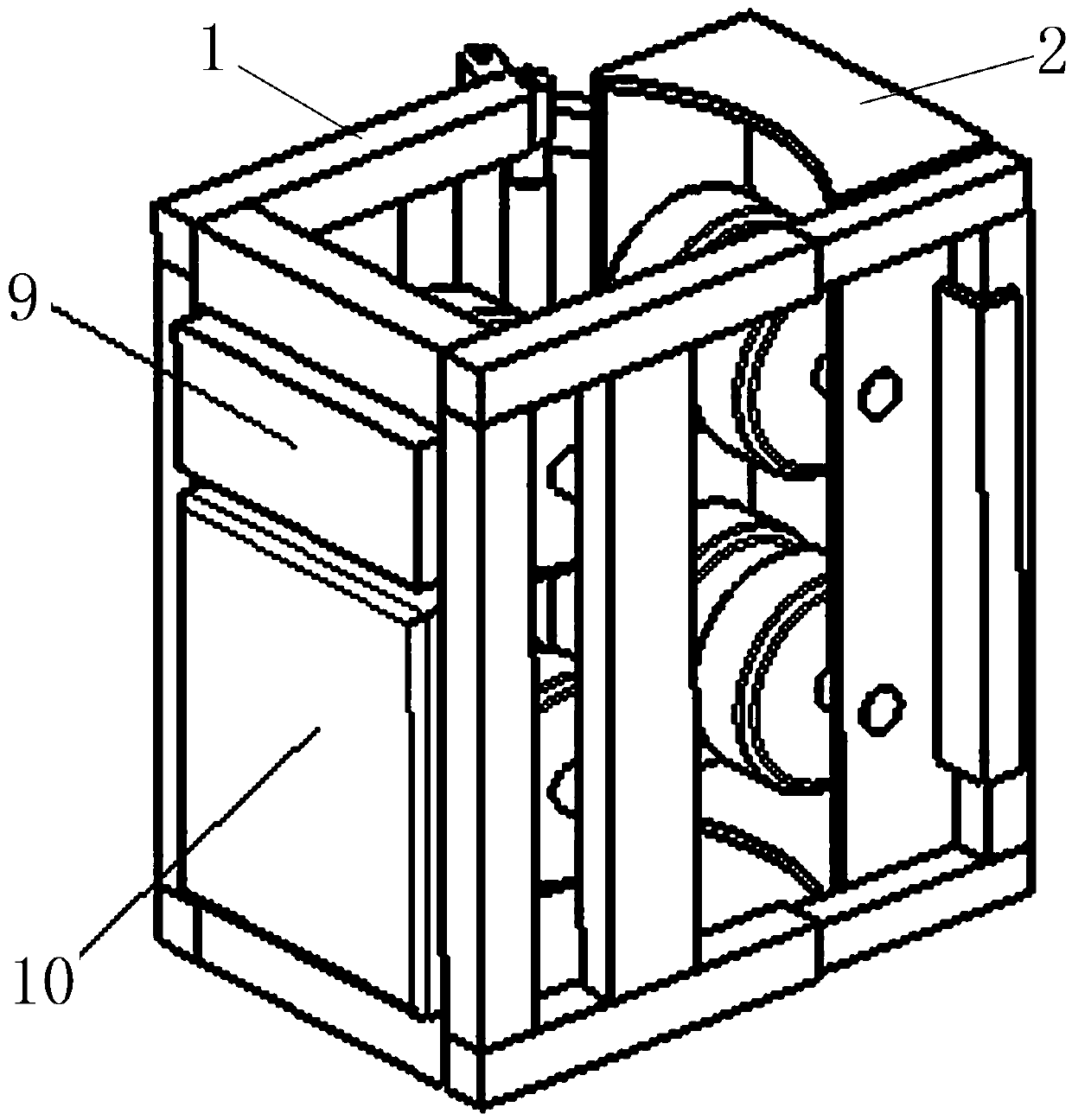

[0050] Embodiment 4: as Figure 9-11 As shown, the difference from Embodiment 3 is that one side of the two frames is respectively rigidly connected to the two ends of a telescopic rod 31 to form a C-shaped frame, and then a hinge 30 is hinged at the opening of the C-shaped frame. Telescopic rod 31, the other end of telescopic rod 31 realizes detachable connection through the hooking cooperation of T-shaped movable hook 5 and fixed hook 6 with a gap for T-shaped hook to hang in the middle on the C-shaped frame. 31 forms an I-shaped structure, and the C-shaped structure and the I-shaped structure are assembled into a rectangular structure, and the approach and separation between the walking wheel mechanisms are realized through the expansion and contraction of the two telescopic rods 31. This embodiment is a C+I-shaped structure. Of course, the T-shaped movable hook 5 in this embodiment can also be replaced by a rectangular hook or a 7-shaped hook.

[0051] In other embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com