Side hydraulic loading system for simulation test bed

A simulated test bench, hydraulic loading technology, applied in the testing of machine/structural components, fluid pressure control in electric mode, using stable tension/pressure to test the strength of materials, etc., can solve the problem of not being able to truly simulate soil conditions, Problems such as low loading pressure and easy damage of the pouch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

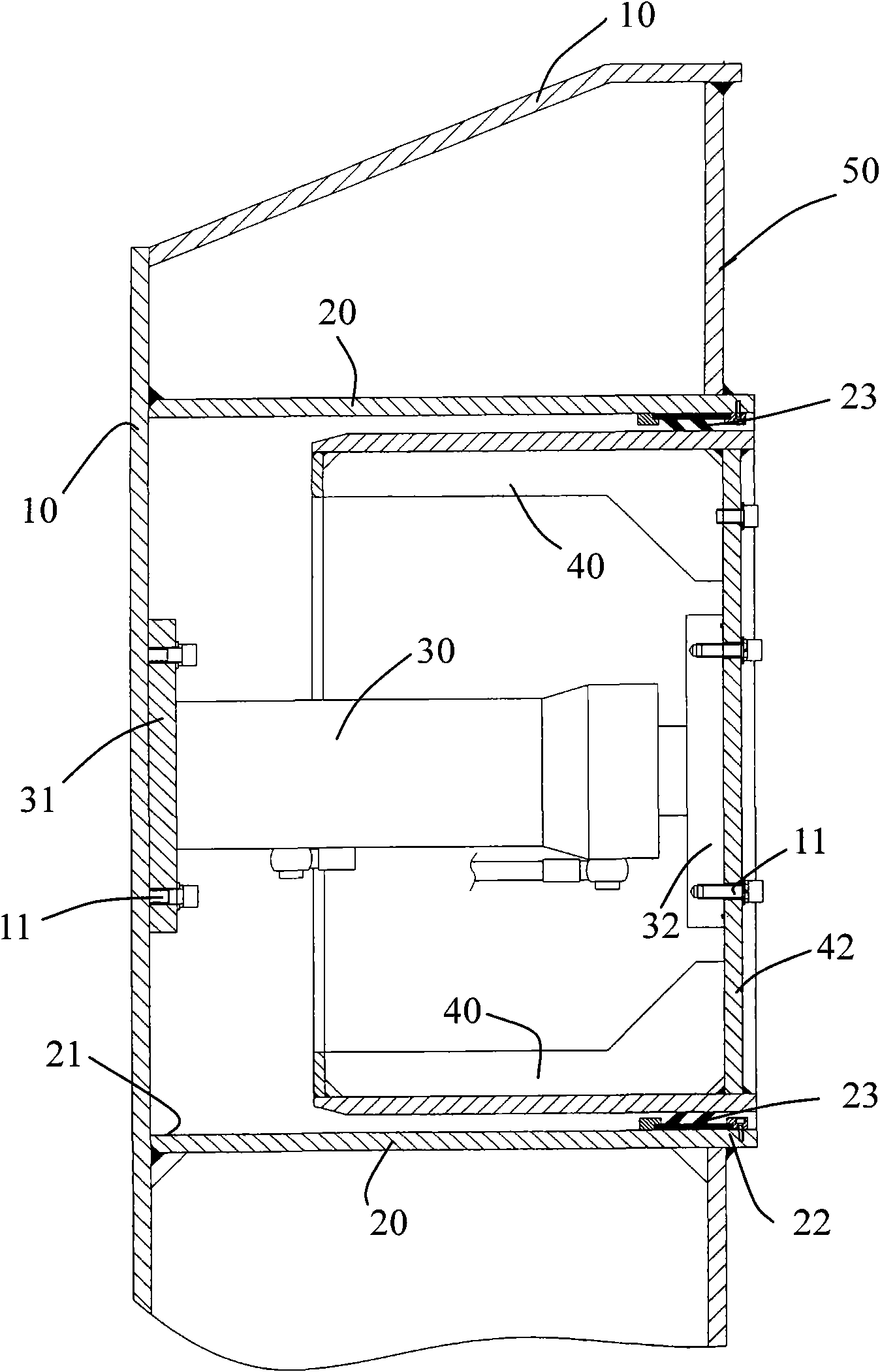

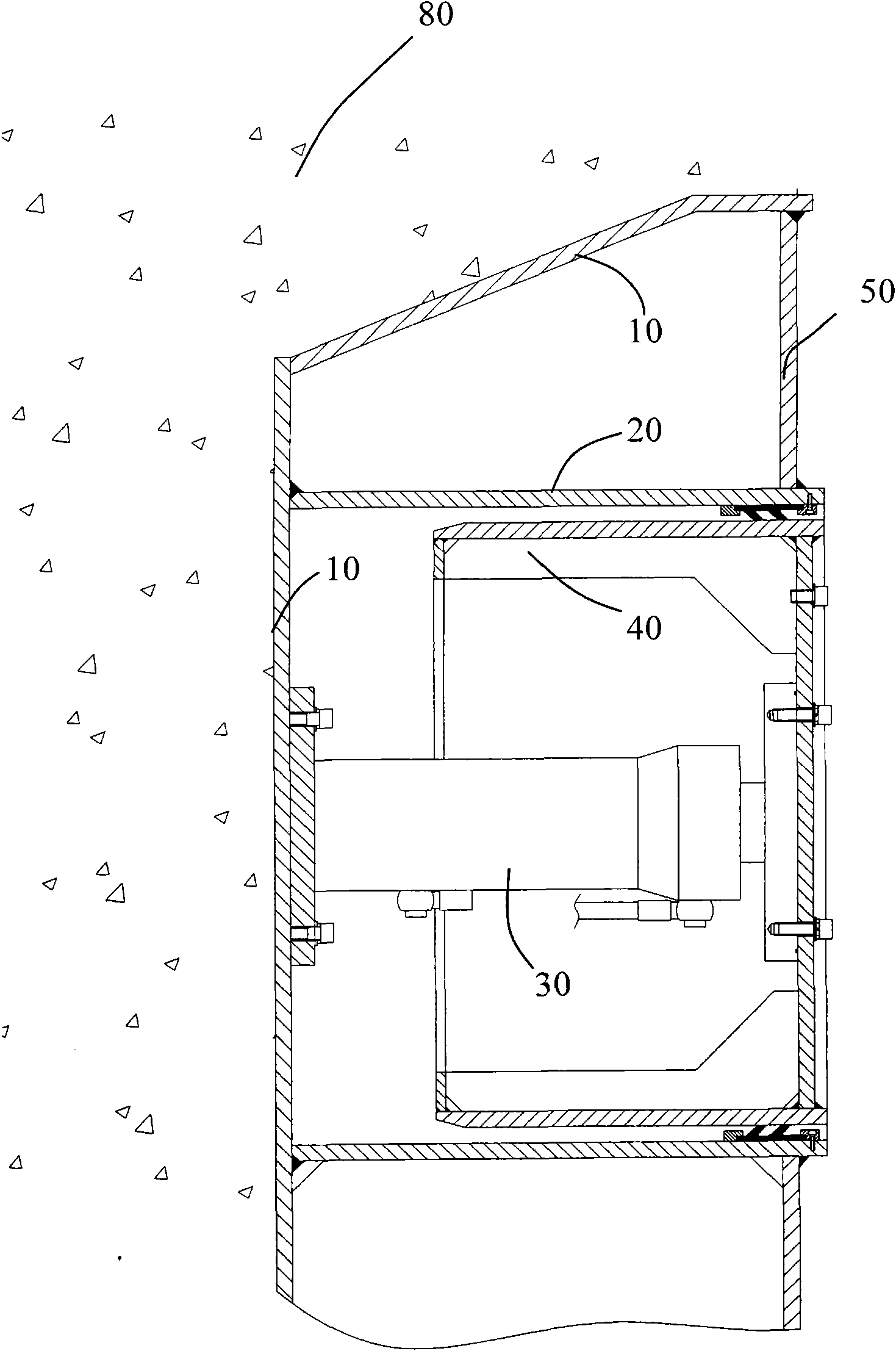

[0019] Such as Figure 1~2 , is a schematic structural diagram of the lateral hydraulic loading device of the present invention, the lateral hydraulic loading device of the present invention includes:

[0020] The pre-embedded steel plate 10 on the side wall is a basic structure;

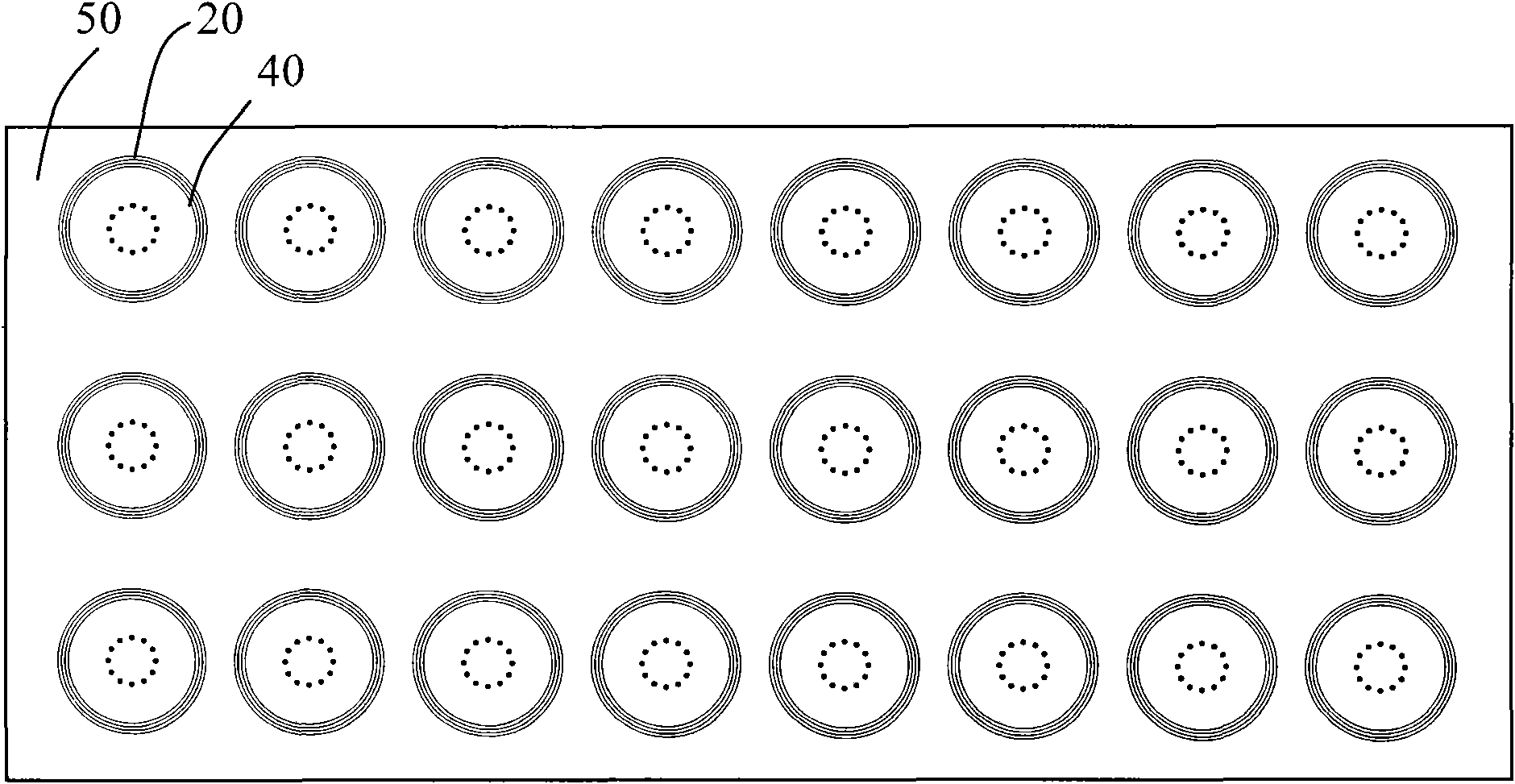

[0021] Some fixed barrels 20, such as figure 2 The present embodiment shown is 24, parallel and evenly arranged, with an inner end 21 and an outer end 22, the inner end 21 of the fixed barrel 20 is fixed on the side wall pre-embedded steel plate 10;

[0022] A number of hydraulic cylinders 30, such as 24 in the present embodiment, are respectively arranged in corresponding fixed barrels 20, and are coaxial with the fixed barrels 20, and can be telescopically operated in the fixed barrels 20. The hydraulic cylinders 30 have an inner end 31 and An outer end 32, the inner end 31 of the hydraulic cylinder 30 is fixedly connected with the lateral pre-embedded steel plate 10 through the bolt 11;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com