Fully-sealed touch control integrated liquid crystal screen and manufacturing process thereof

A fully sealed, liquid crystal screen technology, applied in optics, instruments, electrical and digital data processing, etc., can solve the problems of moiré, low yield, and poor thickness due to differences in display screens, achieve good solid-state fluidity, and save production. The effect of low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

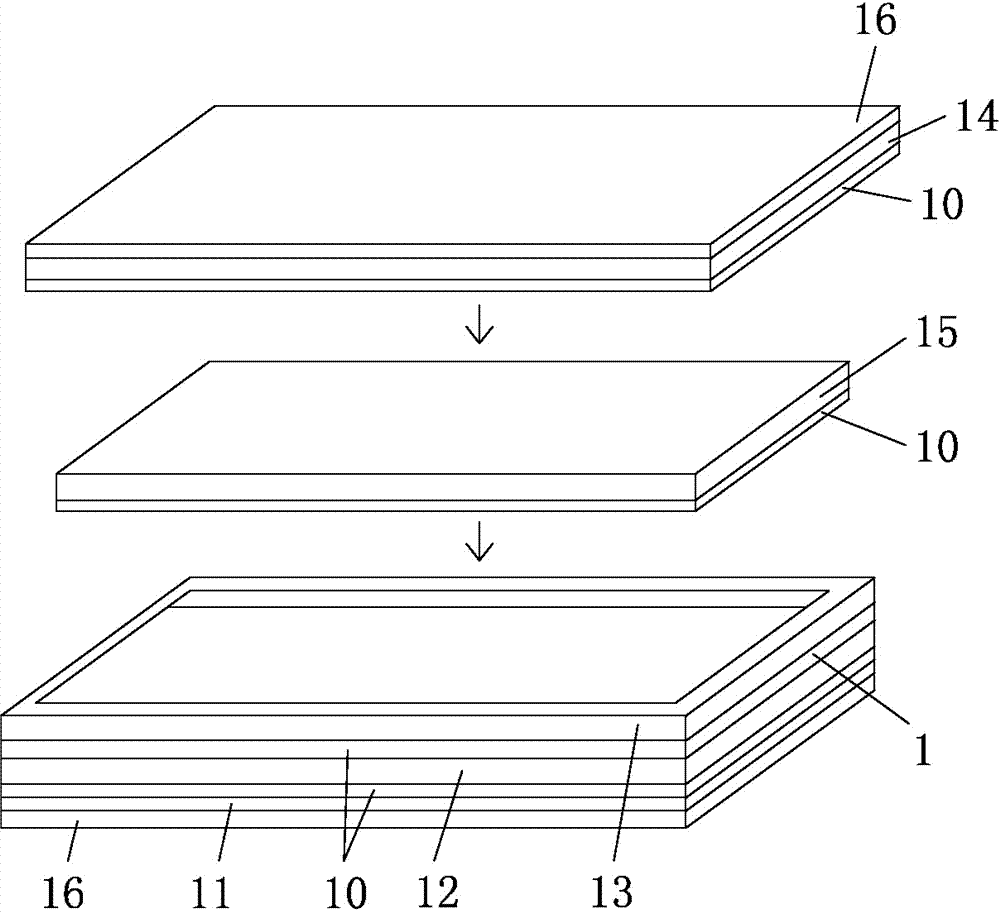

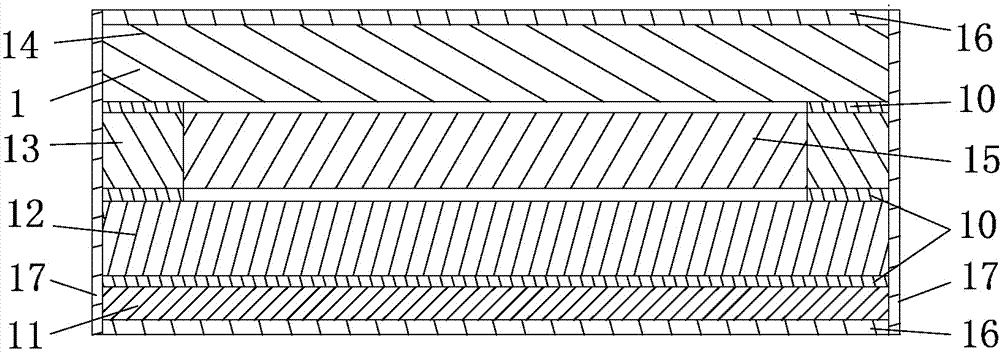

[0026] A manufacturing process for a fully sealed touch-screen liquid crystal integrated screen, which uses solid ultraviolet flexible glue to bond sequentially arranged components to each other to form a whole. The components include a touch screen group, a liquid crystal screen group, a plexiglass frame and a glass cover. A backlight module is embedded between the liquid crystal screen group, the plexiglass frame and the glass cover; the process includes:

[0027] 1) Attach a piece of solid ultraviolet flexible glue with a thickness of 50-100 μm between any two adjacent components, and the backlight module is directly embedded between the LCD screen group, the plexiglass frame and the glass cover;

[0028] 2) Degassing: Put the components attached with solid ultraviolet flexible glue into the autoclave for 10-50 minutes for degassing, control the pressure in the autoclave to 0.5kg-3kg, and the temperature to 30-40℃;

[0029] 3) Curing: Use a high-power UV lamp to irradiate t...

Embodiment 2-3

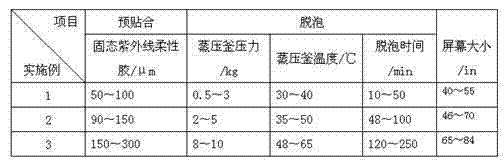

[0035] Table 1

[0036]

[0037] In the embodiment, if the thickness of the solid ultraviolet flexible adhesive is less than 50 μm, the fluidity is not enough, and thickness difference is likely to occur. If the thickness is higher than 300 μm, the fluidity is too full and overflowing glue is likely to occur. If the temperature and pressure are lower than the limit value, the solid ultraviolet flexible adhesive will not be easily bonded to each component; during the defoaming process, the temperature is 30-65°C, the pressure is 0.5-10kg, and the defoaming time is 10-250 minutes. If the value is higher than the limit value, the The resin is easy to soften and cause glue overflow, and it will also produce thickness differences and dullness. In the actual production process, appropriate parameters can be selected within the above numerical range according to the different screen sizes for production.

[0038] The pre-lamination in the technological process of the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com