A method for improving the yield of ogs touch screen produced by large-scale production line

A large-size, touch-screen technology, applied in the direction of layered products, chemical instruments and methods, and data processing input/output processes, can solve the problems of low yield of OGS touch-screen production lines, loss of production enterprises, and easy damage to edges, etc. , to achieve good solid fluidity, improve yield, and solve the effect of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A method for improving the yield rate of touch screens produced by OGS on a large-scale production line, comprising the following steps:

[0015] 1) Use the large-size OGS touch screen production line to coat the surface of large-size ultra-thin glass with IT0 circuit film to form a large-size OGS touch glass substrate;

[0016] 2) Cut the large size OGS touch glass substrate into the required small size OGS touch glass;

[0017] 3) Pre-laminate the small-sized OGS touch glass with the six-sided tempered glass by using solid ultraviolet flexible glue, the thickness of the solid ultraviolet flexible glue is 100-120 μm;

[0018] 4) Put the pre-laminated small-sized OGS touch glass and six-sided tempered glass prepared in step 3 into the autoclave for degassing for 10-250 minutes, control the pressure in the autoclave to 0.5kg-3kg, and the temperature to 30-40°C , forming a transparent glue;

[0019] 5) Use a high-power UV lamp to irradiate the transparent glued body wit...

Embodiment 2-3

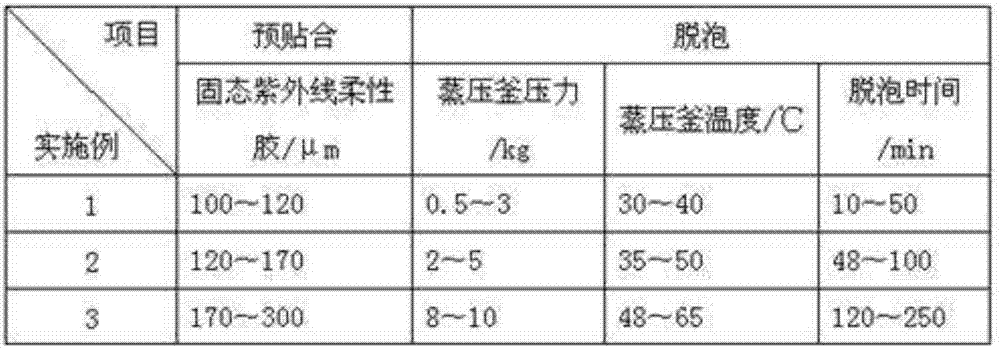

[0021] The same preparation method as in Example 1 was adopted, except that the thickness, pressure and temperature listed in Table 1 in the pre-lamination and defoaming steps were used instead of the corresponding values used in Example 1.

[0022] Table 1

[0023]

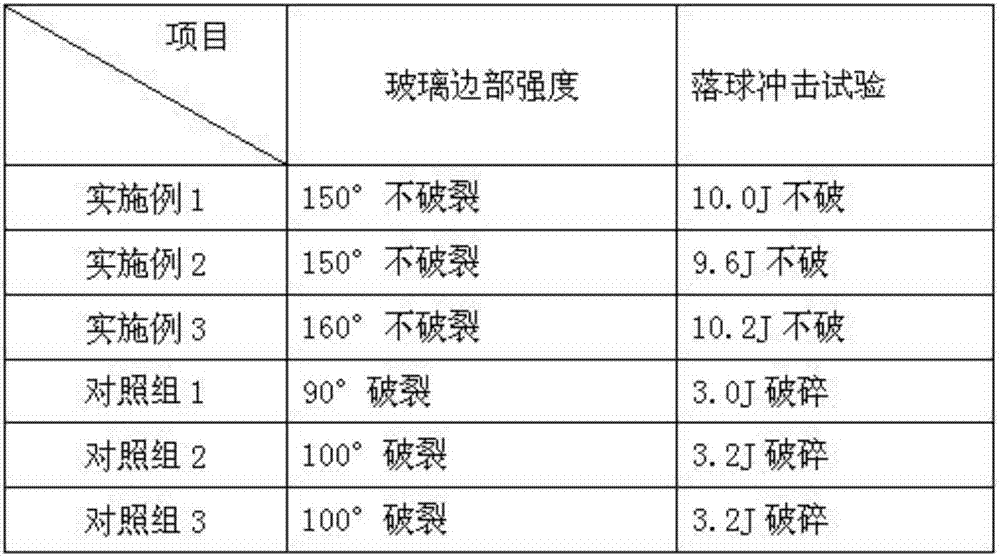

[0024] The finished product obtained by the embodiment of the present invention 1-3, each group of physical detection data is as shown in Table 2 (wherein, the control group 1-3 in Table 2 is the finished product obtained by adopting the original OGS glass production process):

[0025] Table 2

[0026]

[0027] It can be seen from Table 2 that the edge strength of the glass of the finished product obtained in Examples 1-3 of the present invention is stronger than that of the control group, and the result of the falling ball impact test is also better than that of the control group. The new OGS touch screen produced by the technical solution of the present invention utilizes an impact-resistant transparen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com