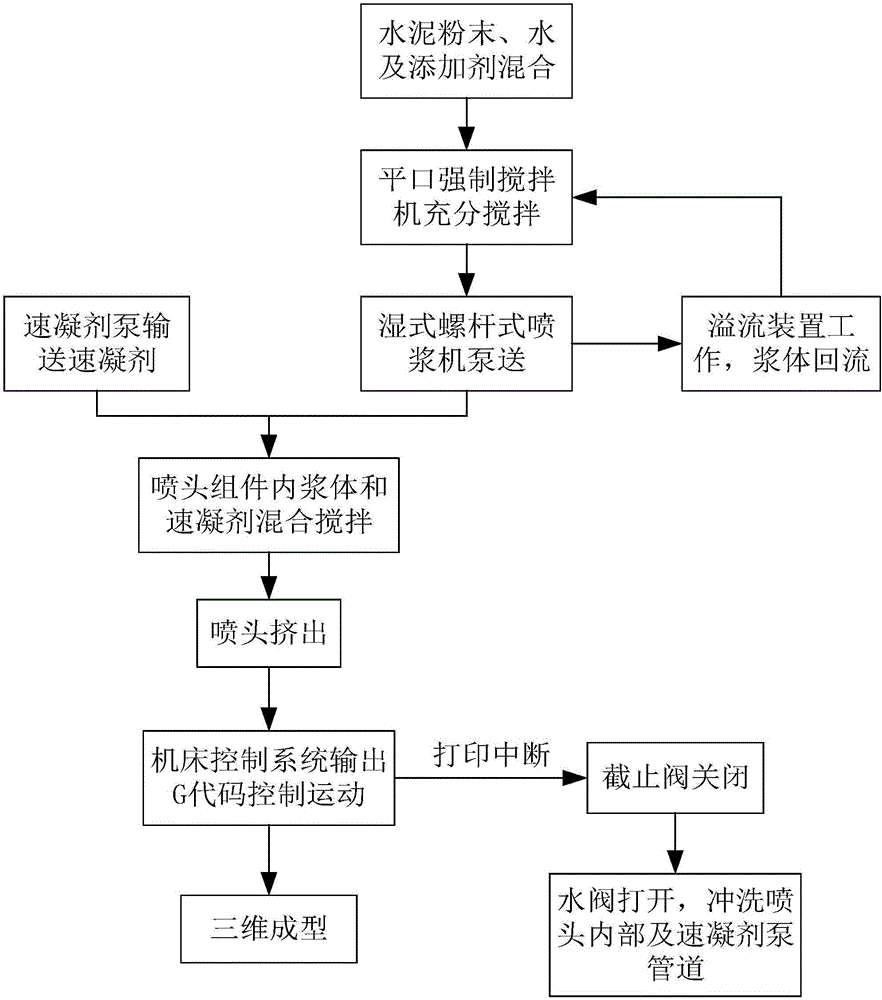

Concrete 3D printing process

A 3D printing and concrete technology, applied in the field of 3D printing technology, can solve problems such as equipment that does not have 3D printing building materials, and achieve the effect of avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

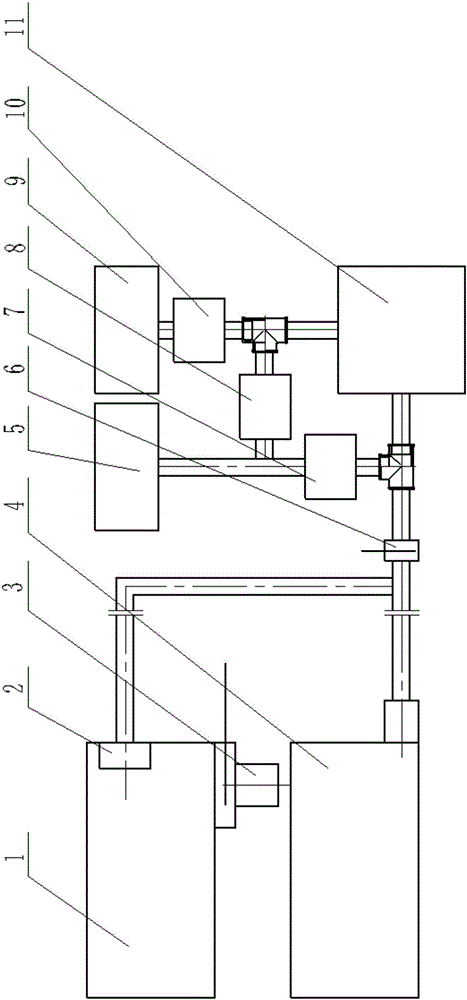

[0026] Further illustrate below in conjunction with accompanying drawing:

[0027] see figure 1 with figure 2 As shown, the present invention includes a concrete 3D printing process, which mainly includes stirring and conveying of concrete slurry, addition of liquid quick-setting agent, addition and mixing of quick-setting agent, cleaning in the nozzle assembly during intermittent printing, and concrete slurry recycling, and the process of molding after extrusion; wherein the stirring of the concrete slurry is realized by using a flat concrete forced mixer 1, and the transportation is pumped out and conveyed by a wet screw spraying machine 4, and the quick-setting The addition and agitation of the agent are realized through the screw rod in the quick-setting agent pump 9 and the nozzle assembly 11, and the cleaning in the nozzle assembly during the intermittent printing is through the high-pressure water pump 5, the first shut-off valve 3, the second shut-off valve 6, The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com