Adjustable fabric winding drum

An adjustable cloth reel technology, applied in the field of adjustable cloth reels, can solve the problems of high labor intensity and low cloth rewinding efficiency, and achieve the effect of improving rewinding efficiency and avoiding frequent replacement of cloth reels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

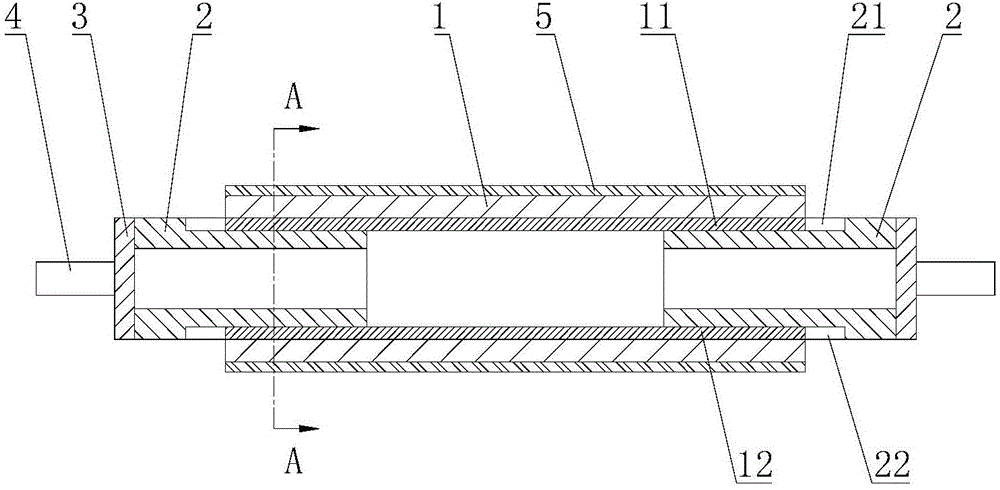

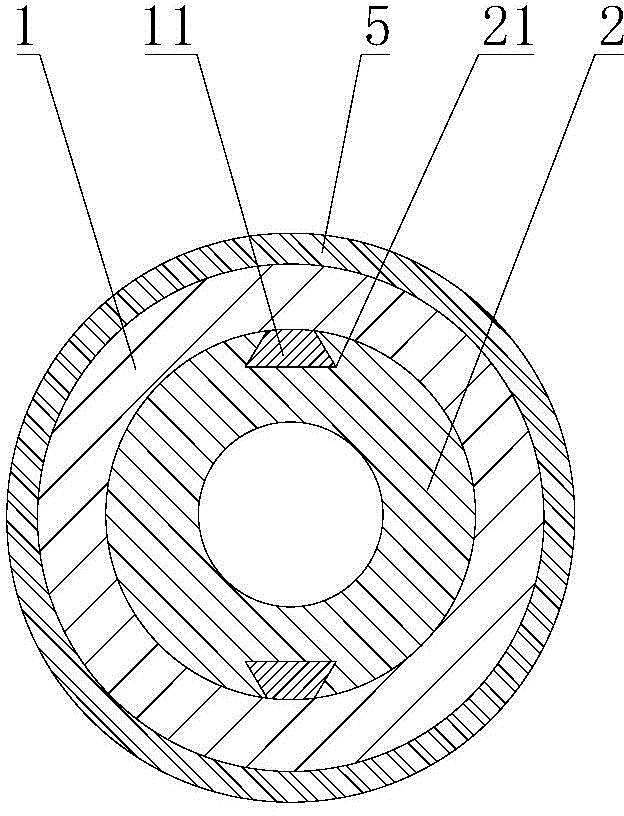

[0016] Combine below Figure 1 to Figure 2 And further illustrate the technical solution of the present invention through specific examples.

[0017] An adjustable cloth roll, comprising a hollow cylinder body 1, telescopic cylinder bodies 2 are respectively sleeved in the inner cavities at both ends of the cylinder body 1, and end caps 3 are arranged on the outer ends of the telescopic cylinder body 2, and the end caps 3 are fixed Connected with a rotating shaft 4, the outer peripheral wall of the telescopic cylinder 2 is provided with a chute group along the length direction of the telescopic cylinder 2. The chute group includes a first chute 21 and a second chute 22 opposite to each other. The inner wall of the cylinder 1 Along the length direction of the cylinder body 1 is provided a slide block set matched with the chute set, and the slide block set includes a first slide block 11 and a second slide block 12 opposite to each other. The combination of the chute group and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com