Improved skip weight-fixed loading equipment

A loading equipment, improved technology, applied in the field of weighing, can solve the problems of low economy, low loading accuracy, inaccurate weighing, etc., to avoid the replacement of load cells, reduce maintenance costs, and increase service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

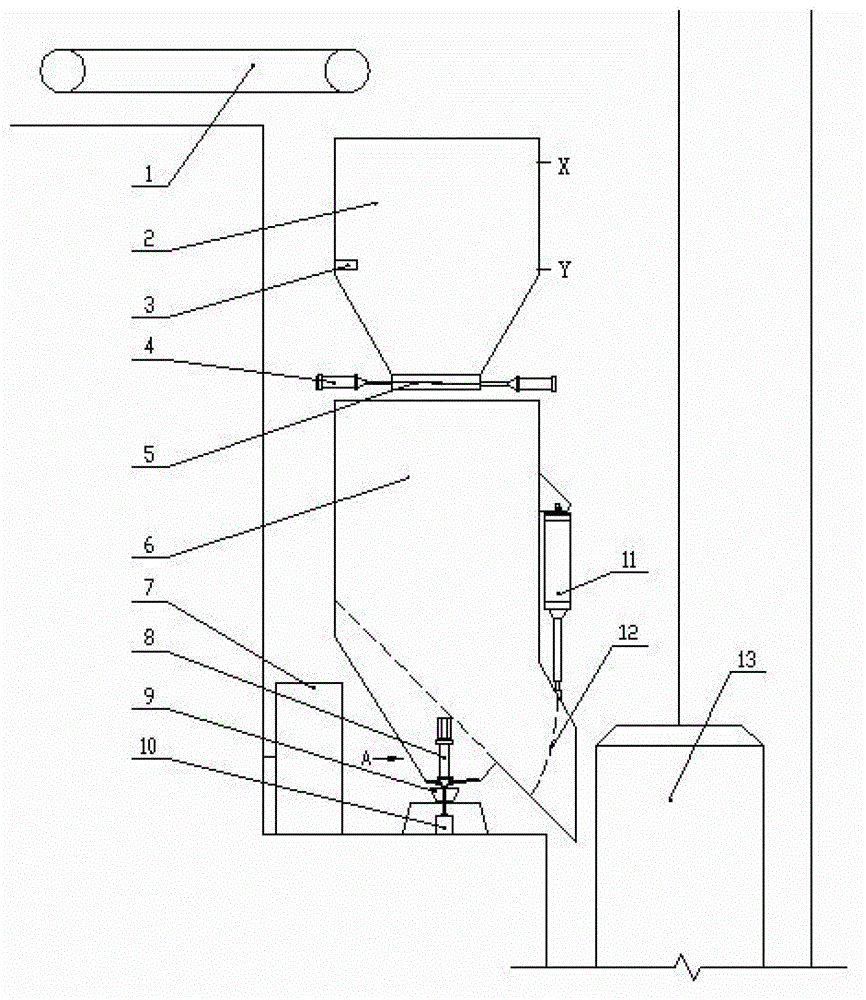

[0013] The present invention will be further described below in conjunction with accompanying drawing.

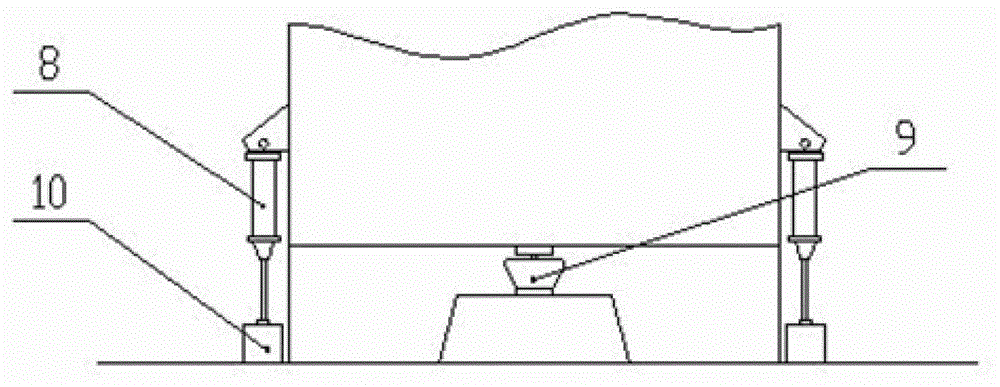

[0014] like figure 1 and figure 2 As shown, the present invention comprises quantitative bucket 6, weighing sensor 9, fan-shaped gate oil cylinder 11 and fan-shaped gate 12, and fan-shaped gate 12 is installed at the discharge port of quantitative bucket 6, and weighing sensor 9 is installed at the bottom of quantitative bucket 6, and fan-shaped The gate oil cylinder 11 is welded on the side wall of the quantitative bucket 6, and the sector gate 12 is connected with the sector gate oil cylinder 11. It also includes a buffer bin 2 and a standard weight 10. A coal level gauge 3 is installed inside the buffer bin 2. The buffer bin 2 is installed under the chute of the belt conveyor 1. The buffer bin 2 is an inverted cone structure. The discharge of the buffer bin 2 The opening is located at the bottom of the bin, and a flat gate 5 is installed at the discharge port. The fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com