Paraffin sizing material for electronic cloth of low solid content

A low solid content, sizing technology, applied in the field of continuous non-alkali glass fiber yarn, can solve the problems of high sizing agent residue on the cloth surface, affecting the use effect, etc., and achieve reduced sizing agent residue, cost reduction, and good social benefits and economical effects

Inactive Publication Date: 2008-11-19

山东兴国大成特种纤维科技有限公司

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

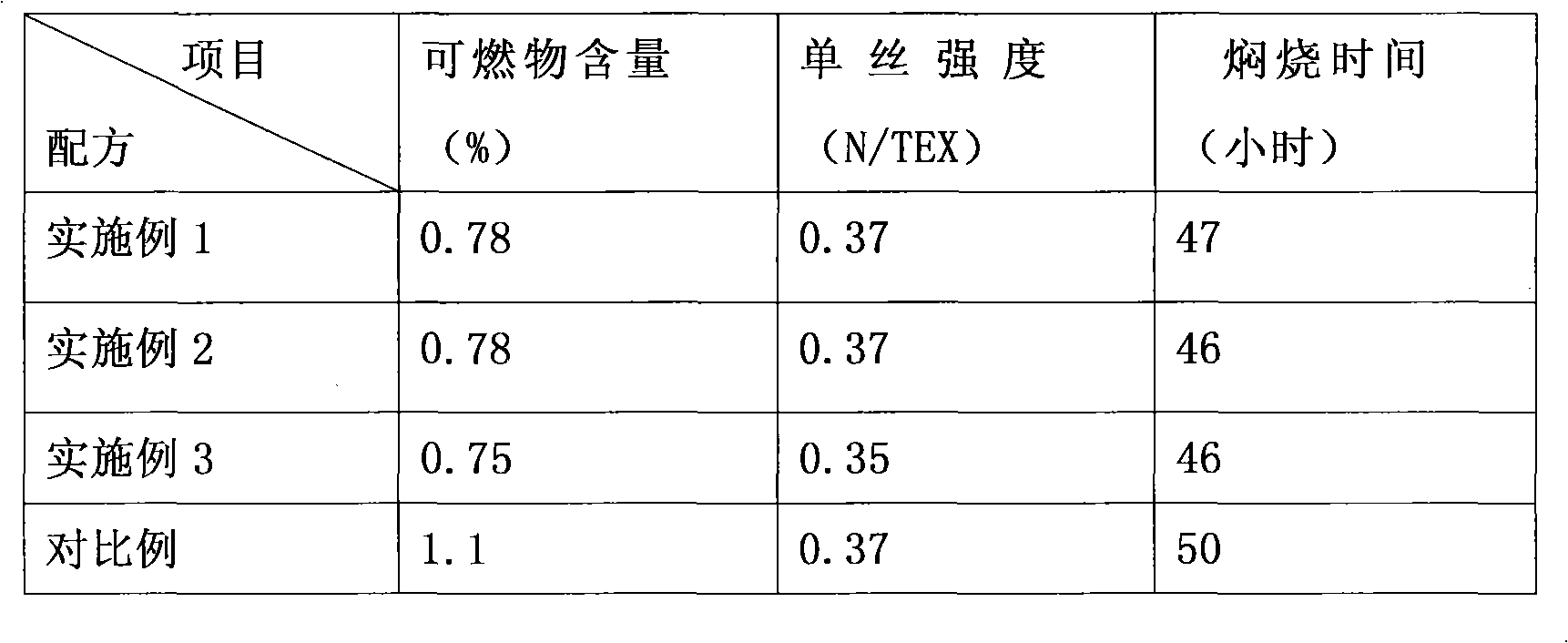

The invention relates to a paraffin wax impregnating compound with low solid content used by an electronic cloth. The compositions by weight percentage of the paraffin wax impregnating compound are: 1.2 to 1.5 percent of paraffin wax, 0.8 to 1.5 percent of engine oil, 0.8 to 1.5 percent of vaseline, 0.6 to 0.8 percent of emulsifying agent, 0.1 to 0.15 percent of cationic film, 2.5 to 3.8 percent of fixing agent, the balance being water. Moreover, epoxy resin can be also added into the compositions and occupies 0.3 to 0.5 percent of the total weight. The invention reduces the amount of oil substances such as the paraffin wax, the vaseline, the engine oil and so on in the compositions of the impregnating compound and adds the cationic film with a certain proportion. Glass fiber yarns the surface of which is coated by the impregnating compound are soft and have good weaving performance and low combustible content. According to actual detection, the combustible content of the glass fiber yarns produced by the formula is between 0.75 and 0.85 percent and reduces by 15 to 25 percent compared with 1 percent of combustible content of the prior paraffin wax yarns, and the production cost is reduced.

Description

Paraffin-type sizing for electronic cloth with low solid content technical field The invention relates to a modified paraffin-type glass fiber sizing formulation with low solid content, which is especially suitable for producing continuous alkali-free glass fiber yarns with a single filament diameter of 9 microns for weaving electronic cloth. Background technique At present, the lubricating components in the known glass fiber paraffin-type sizing formulations all use oils such as paraffin, petrolatum, machine oil or transformer oil. The solid content of the glass fiber sizing agent is high, causing the sizing agent content of the drawn glass fiber yarn to be above 1%. Before using the electronic cloth woven with this kind of glass fiber yarn, all the sizing agent on the cloth surface needs to be sintered at high temperature, and a large amount of electric energy is consumed in the sintering process. Moreover, due to the high content of the sizing agent in the glass fiber ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C25/24

Inventor 张宗生刘敬文王增春

Owner 山东兴国大成特种纤维科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com