Basalt fiber unidirectional cloth for reinforcing engineering structure and manufacturing method of basalt fiber unidirectional cloth

A technology of basalt fiber and engineering structure, which is applied to textiles, papermaking, textiles, fabrics, etc., can solve the problems of low electrical conductivity, high cost of use, and high thermal conductivity, and achieve reduced baking time, uniform internal force, and combined high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below by specific embodiments:

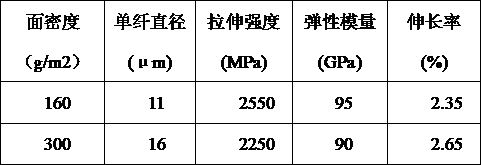

[0034] This embodiment provides an engineering structure to reinforce the basalt fiber single-way cloth, specifically,

[0035] An engineering structure reinforced with basalt fiber single-way cloth, using prefabricated continuous basalt fibers as warp yarns, hot melt is the weft yarns; the textile is used in the textile, and there is a certain gap between adjacent warp yarns. Fabric.

[0036] The thermal filament plays a fixed and retention of the fabric structure, with a mass ratio of no more than 7%.

[0037] The hot melt can be low-melting organic fibers, preferably a polyester or nylon having a melting point at 90 ° C to 150 ° C.

[0038] There is a gap between adjacent warp yarns, preferably, gap size at 0.5 mm to 5 mm.

[0039] Prefabricated continuous basalt fibers, its surface willing is not fully formed, and can be synchronized with the thermal fuse melt formation, thereby i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com