Alginate fiber containing tremella polysaccharide and preparation method thereof

A technology of tremella polysaccharide and seaweed fiber, which is applied in the field of fiber materials, can solve the problems of decreased utilization rate of mask essence, reduced mask skin care effect, poor moisturizing effect, etc., and achieves good application prospects, excellent textile effect, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

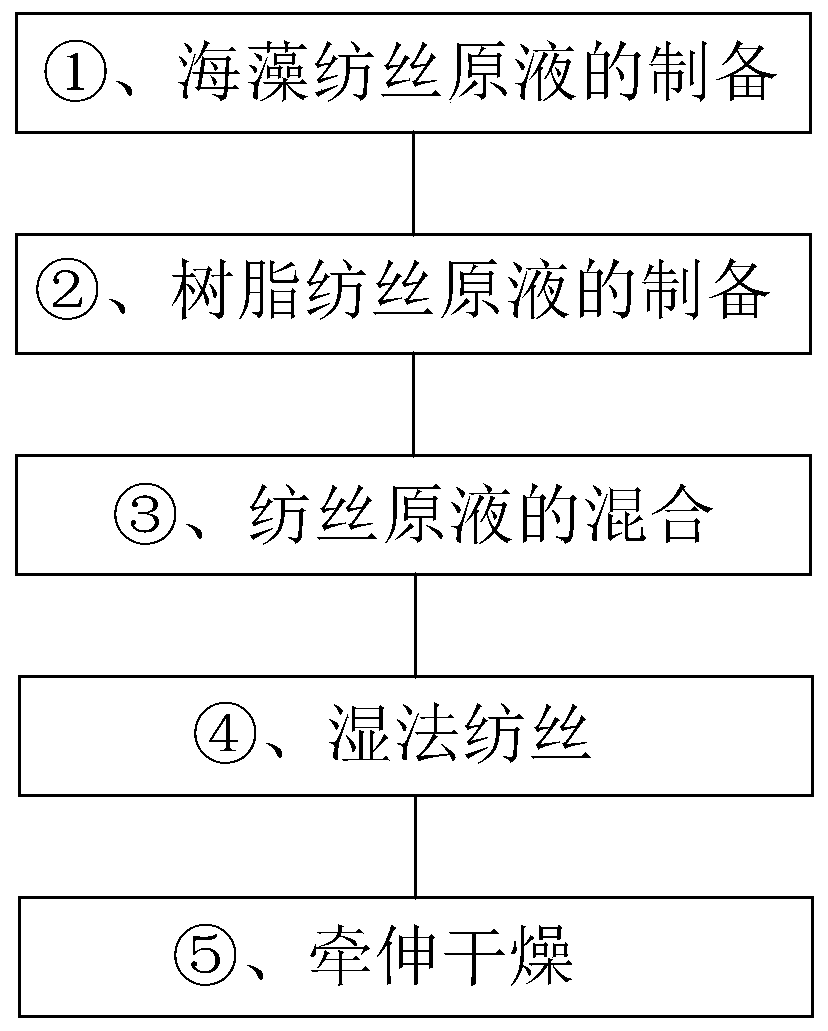

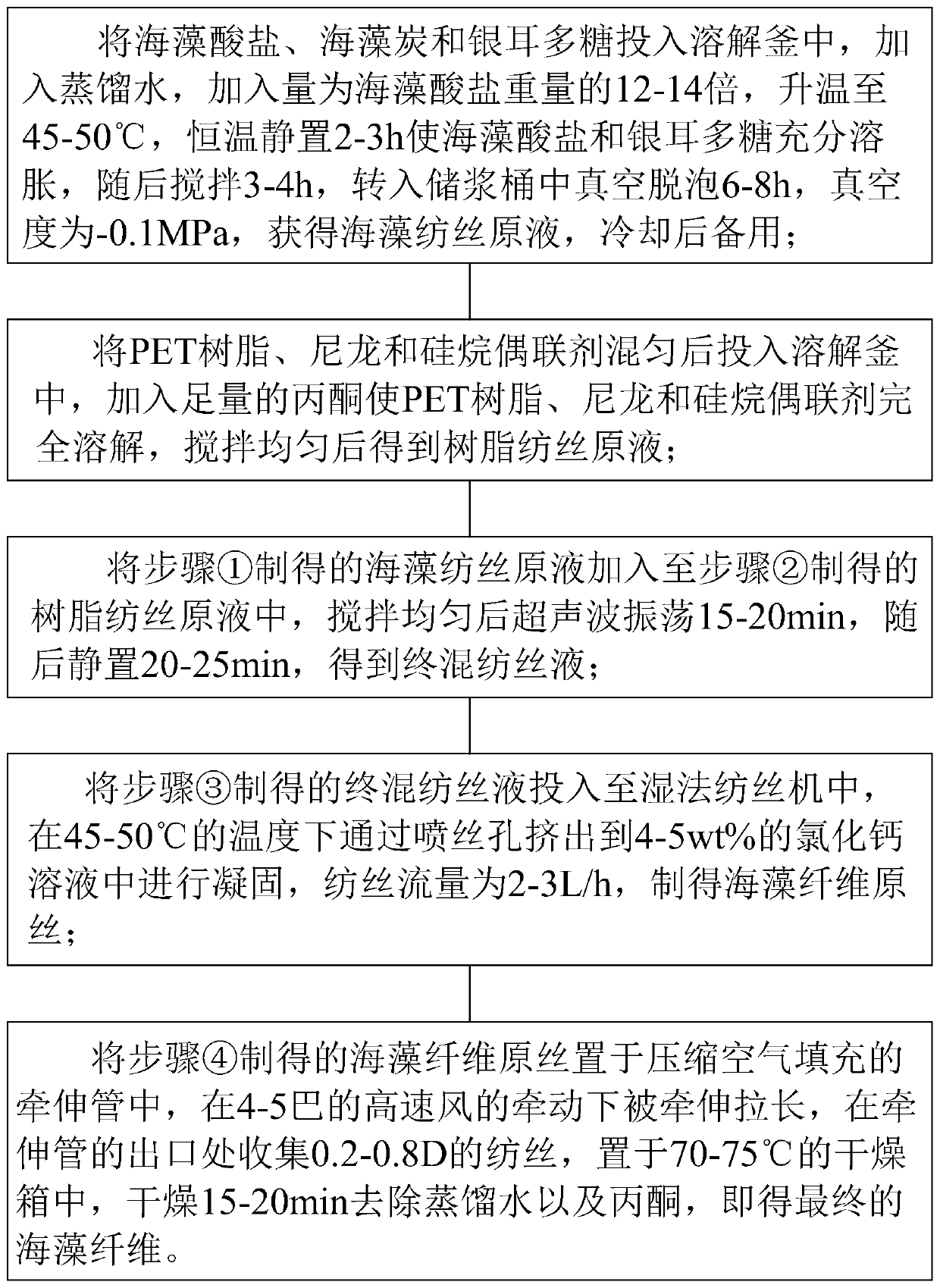

[0078] A kind of preparation method of the seaweed fiber containing tremella polysaccharide, see figure 1 and figure 2 , including the following steps:

[0079] ①. Preparation of seaweed spinning stock solution:

[0080] Put the alginate, seaweed charcoal and tremella polysaccharide into the dissolving kettle, add distilled water, the amount added is 12 times the weight of the alginate, raise the temperature to 50°C, let stand at constant temperature for 2 hours to fully swell the alginate and tremella polysaccharide, then stir 3h, transfer to the pulp storage tank for vacuum defoaming for 6h, the vacuum degree is -0.1MPa, obtain the seaweed spinning stock solution, cool and set aside;

[0081] ②. Preparation of resin spinning stock solution:

[0082] Put the PET resin, nylon and silane coupling agent into the dissolving kettle after mixing, add enough acetone to completely dissolve the PET resin, nylon and silane coupling agent, and get the resin spinning stock solution a...

Embodiment 2-4

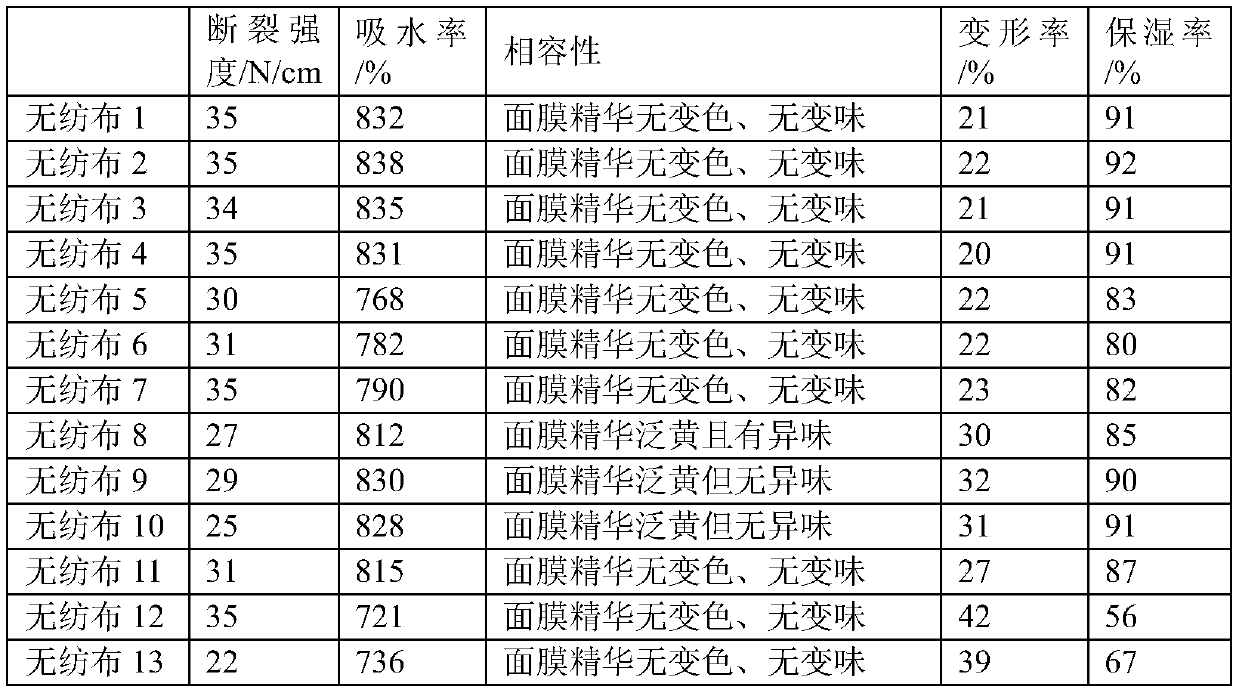

[0090] Examples 2-4 are all based on the method of Example 1, and the component parameters and preparation parameters of the seaweed fiber are adjusted, and the specific adjustments are shown in Table 1 below.

[0091] Component parameter and preparation parameter table of table 1 embodiment 1-4

[0092] Example 1 Example 2 Example 3 Example 4 PET-GF15 28 25 30 27 nylon 23 26 22 25 polyethylene wax 6 5 8 7 Alginate 22 22 20 24 Seaweed charcoal a 9 8 9 10 tremella polysaccharide 4 5 4 3 Coupling agent KH550 6 5 7 8 Multiples of distilled water 12 13 14 12 temperature / ℃ 50 45 48 45 Standing time / h 2 2.5 3 2 Stirring time / h 3 3.5 3.5 4 Vacuum defoaming time / h 6 8 7 6 Ultrasonic time / min 18 15 20 20 Standing time / min 25 20 22 24 Spinning temperature / ℃ 48 50 45 45 Calcium chloride concentration / wt% 4 5 4.5 4 Spinning fl...

Embodiment 5

[0094] Embodiment 5-6 In the method of embodiment 1, adjust the specific composition of alginate. Wherein, the alginate in Example 5 is potassium alginate; the alginate in Example 6 is sodium alginate.

[0095] 2.4, Embodiment 7

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com