Preparation method of flexible acid-resistant temperature-resistant glass modified fibers

A glass fiber and temperature-resistant technology, which is applied in the field of preparation of flexible acid-resistant and temperature-resistant modified glass limiters, can solve the problems of poor wear resistance, poor plasticity, thermal stability and thermal expansion coefficient of glass fibers, and achieves difficult separation. , good flexibility, good production and processing performance and the effect of textile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

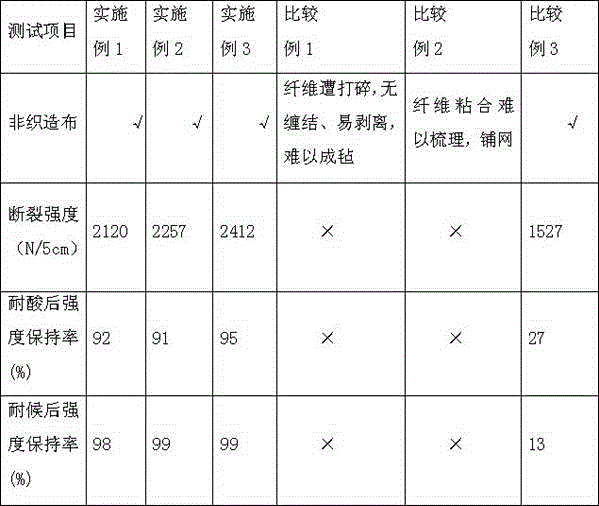

Examples

Embodiment 1

[0017] Glass fiber dispersion and pretreatment: add glass fiber to the acid solution composed of hydrogen peroxide, acetic acid, and lauric acid, disperse with ultrasonic oscillation, the frequency is 30KHz, and the time is 40min, and then add methacrylic acid with glass fiber content of 0.2%wt. For acyloxypropyltrimethoxysilane, increase the ultrasonic oscillation frequency to 80KHz, and the treatment time is 15min.

[0018] Place the pretreated glass fiber in dimethylformamide with a water content of less than 5%, heat it up to 50°C, and add (3,3,3-trifluoropropyl) trimethoxy with a glass fiber content of 5%wt. (3-Chloropropyl)trimethoxysilane with a glass fiber content of 8%wt., ultrasonically oscillated at a frequency of 50KHz for 60min, washed with water, and dried in vacuum at 120°C for 1.5h to obtain a nonwoven fabric Modified glass fiber with flexible acid and temperature resistance.

Embodiment 2

[0020] Glass fiber dispersion and pretreatment: Add glass fiber to the mixed acid solution composed of sulfuric acid and acetic acid with a mass concentration of 30%, ultrasonically oscillate and disperse at a frequency of 50KHz for 20min, and then add glass fiber content 1.5%wt. Ethyl silicate, increase the ultrasonic oscillation frequency to 100KHz, and process for 30 minutes.

[0021] Place the pretreated glass fiber in dimethylformamide with a water content of less than 5%, heat it up to 70°C, and add (3,3,3-trifluoropropyl) trimethoxy with a glass fiber content of 20%wt. Add (3-chloropropyl)trimethoxysilane with a glass fiber content of 12%wt., ultrasonically oscillate at a frequency of 80KHz for 40min, wash with water, and dry in vacuum at 120°C for 3h to obtain nonwoven fabrics. Flexible acid-resistant and temperature-resistant modified glass fiber.

Embodiment 3

[0023] Glass fiber dispersion and pretreatment: Add glass fiber to the mixed acid solution composed of lauric acid and palm tree, disperse by ultrasonic vibration, the frequency is 40KHz, and the time is 30min, then add γ-glycidol with a glass fiber content of 1.0%wt. Etheroxypropyltrimethoxysilane, methoxypropyltrimethoxysilane methacrylate, γ-aminopropyltriethoxysilane, γ-aminopropylmethyldimethoxysilane (the composition ratio is 3 :3:3:1), increase the ultrasonic oscillation frequency to 90KHz, and the processing time is 20min.

[0024] Place the pretreated glass fiber in dimethylformamide with a water content of less than 5%, heat it up to 60°C, and add (3,3,3-trifluoropropyl) trimethoxy with a glass fiber content of 10%wt. (3-Chloropropyl)trimethoxysilane with a glass fiber content of 10%wt., ultrasonically oscillated at a frequency of 70KHz for 50min, washed with water, and vacuum-dried at 120°C for 2h to obtain nonwoven fabrics Flexible acid-resistant and temperature-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com