Microfluidic chip electrode for electrochemical detection and method for manufacturing microfluidic chip

A microfluidic chip and manufacturing method technology, applied in the direction of material electrochemical variables, etc., can solve the problems of complex electroplating process, difficulty in popularization, and complicated etching process, etc., and achieve the effect of simple manufacturing method, fast time, and easy electrode shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

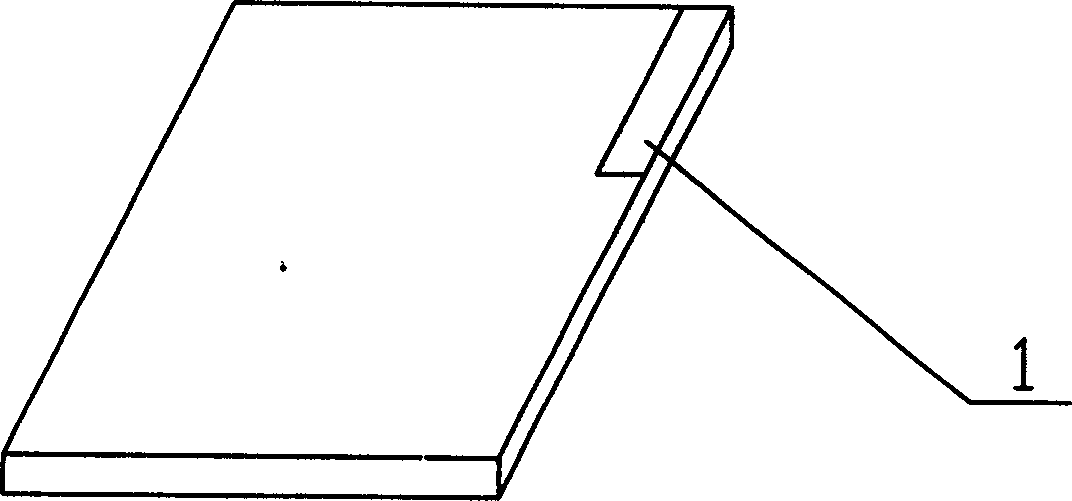

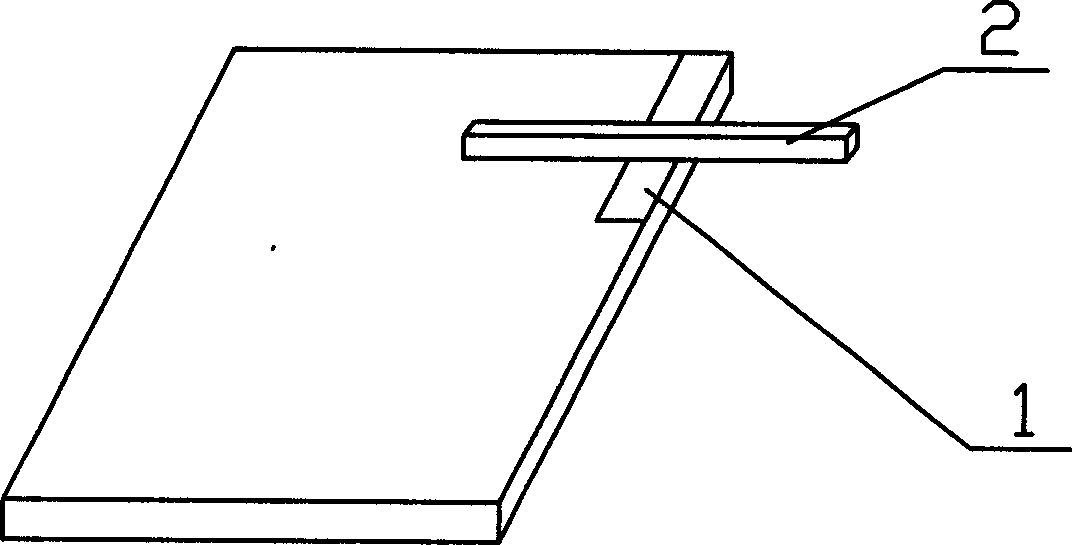

[0016] exist figure 1 , take a piece of cut conductive glass, let the side with ITO conductive film face up ( figure 1 ), paint the rectangle 1 with Vaseline at one corner of the glass, this position is protected by Vaseline, after the etching is completed, it will be the position of the electrode connecting sheet 4 ( figure 2 ). Take a metal strip 2 coated with vaseline on the surface, and place it in the middle of the rectangular vaseline. In addition to the rectangular vaseline part, the part where the conductive glass contacts the metal strip is also protected by the vaseline ( image 3 ). Soak the conductive glass with metal strips in 5mol / L hydrochloric acid solution for 30 minutes ( Figure 4 ). After taking out the glass piece, remove the metal strip, wipe off the vaseline on the glass piece, wash the glass surface with absolute ethanol and secondary water, and the ITO working electrode 3 and the electrode connecting piece 4 have just been integrated on the glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com