Ethylene-propylene-diene monomer composition

A technology for EPDM rubber and composition, applied in the rubber field, can solve the problems of single, low effect, low bond energy, etc., and achieve the effects of high chemical stability, good protection, and high bond energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Raw material composition

parts by mass

EPDM

100

Quickly squeeze out N550

160

Paraffin oil

10

3

Antiaging agent RD

1

Antiager MB

1

polyethylene glycol

2

Auxiliary cross-linking agent TAC

1

Bis(tert-butylperoxycumene)benzene

10

total

288

[0020] Mixing and processing according to the raw materials and dosage in the listed formula: weighing of rubber and raw materials - one stage of internal mixing - one stage of open mixing - next piece - second stage of internal mixing - second stage of open mixing - next piece - vulcanized rubber sheet - cut according to the standard Pattern - for experimental testing.

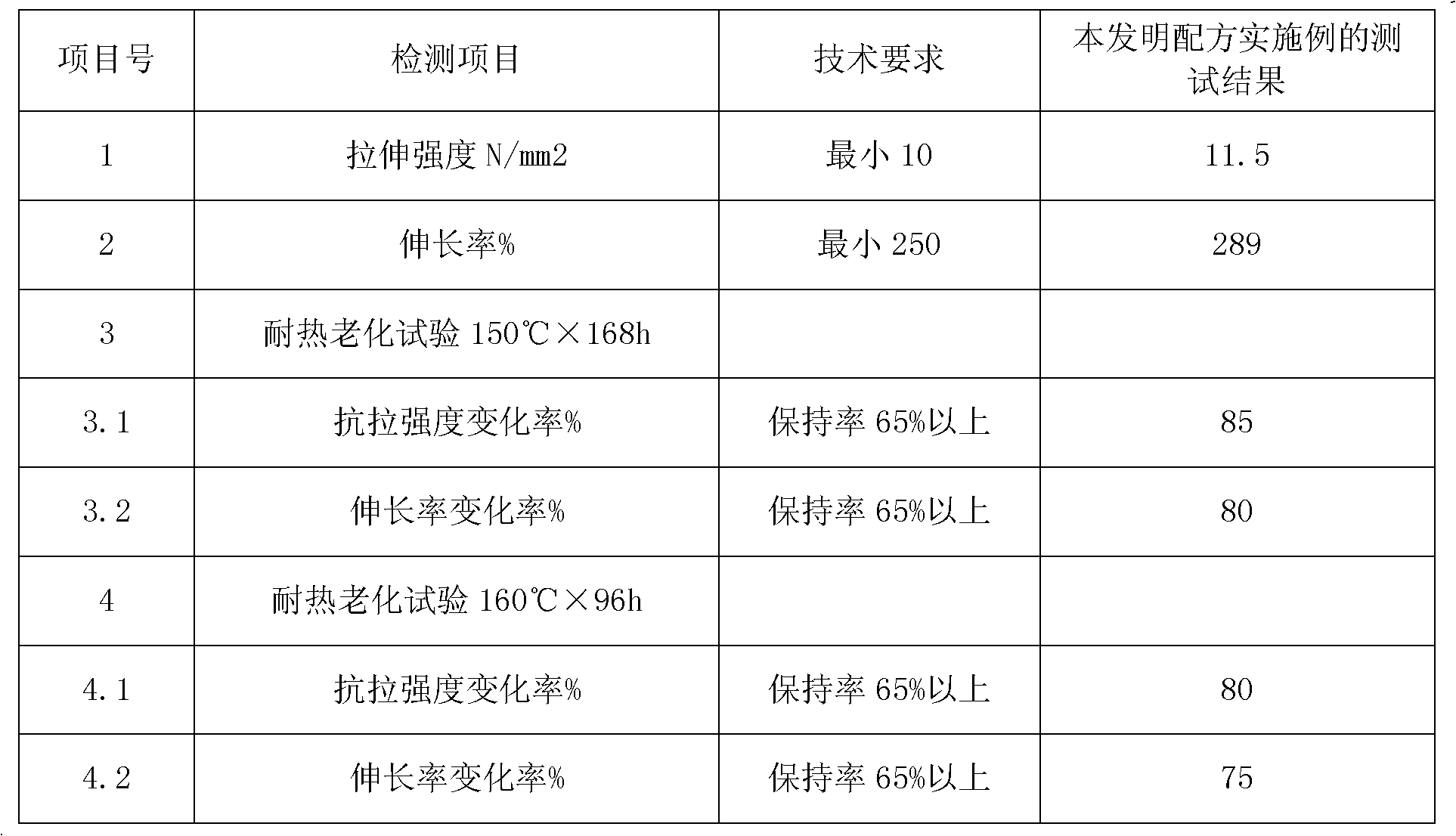

[0021] The following are the performance test results of EPDM rubber:

[0022]

Embodiment 2

[0025] Raw material composition

parts by mass

EPDM

100

Quickly squeeze out N550

100

Paraffin oil

40

5

Antiaging agent RD

2

Antiager MB

2

polyethylene glycol

4

Auxiliary cross-linking agent TAC

5

Bis(tert-butylperoxycumene)benzene

2

total

260

[0026] Mixing and processing according to the raw materials and dosage in the listed formula: weighing of rubber and raw materials - one stage of internal mixing - one stage of open mixing - next piece - second stage of internal mixing - second stage of open mixing - next piece - vulcanized rubber sheet - cut according to the standard Pattern - for experimental testing.

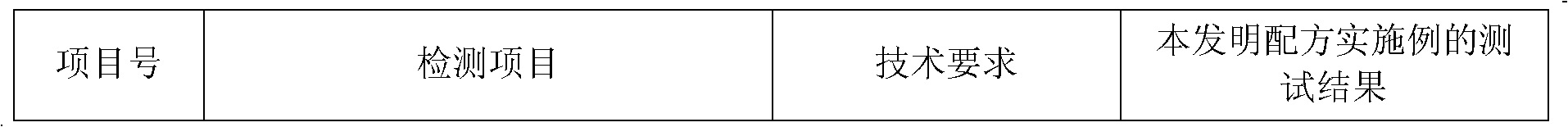

[0027] The following are the performance test results of EPDM rubber:

[0028]

[0029]

Embodiment 3

[0032] Mixing and processing according to the raw materials and dosage in the listed formula: weighing of rubber and raw materials - one stage of internal mixing - one stage of open mixing - next piece - second stage of internal mixing - second stage of open mixing - next piece - vulcanized rubber sheet - cut according to the standard Pattern - for experimental testing.

[0033] The following are the performance test results of EPDM rubber:

[0034]

[0035]

[0036] By analyzing the results obtained from the above formula, the EPDM formula of this invention has met the retention rate of the tensile properties (strength and elongation at break) under high-temperature thermal aging conditions at more than 65%, so it is better It embodies the advantage of the formula of the present invention in the thermal aging resistance of EPDM rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com