Innocent treatment method for sulfur-bearing VOC

A technology of harmless treatment and treatment equipment, applied in the direction of combustion method, incinerator, combustion type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

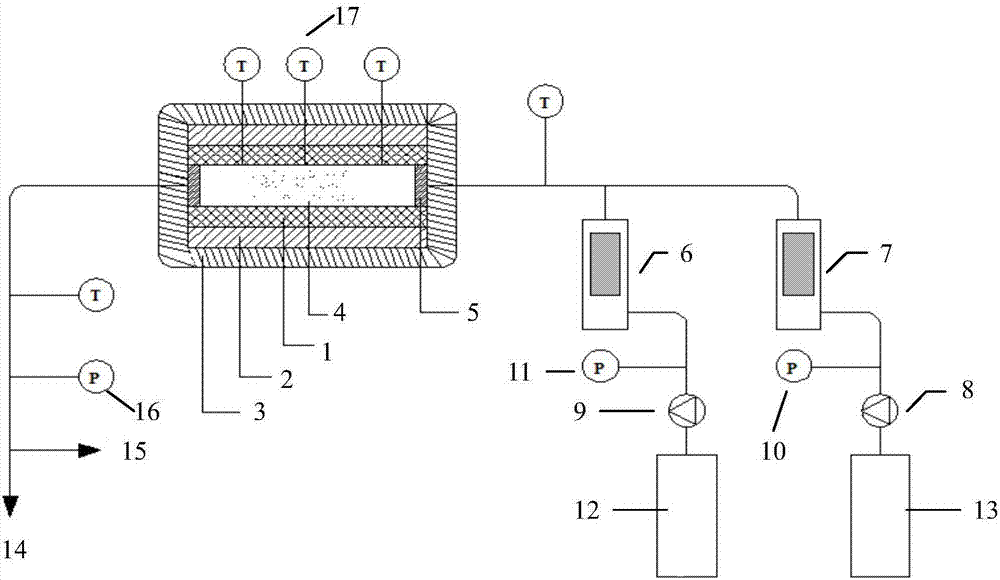

[0055] (1) Cuprous oxide (Cu) with a particle size of 0.1mm 2 O) powder and metal cerium dioxide (CeO) with a particle size of 0.1 mm 2 ) according to the mass ratio of 8:2, mix evenly, and fill to such as figure 1 In the shown ceramic tube with an inner diameter of 50 mm and a length of 800 mm, a barrier layer is provided at both ends of the ceramic tube, and the barrier layer is respectively provided with an air outlet and an air inlet;

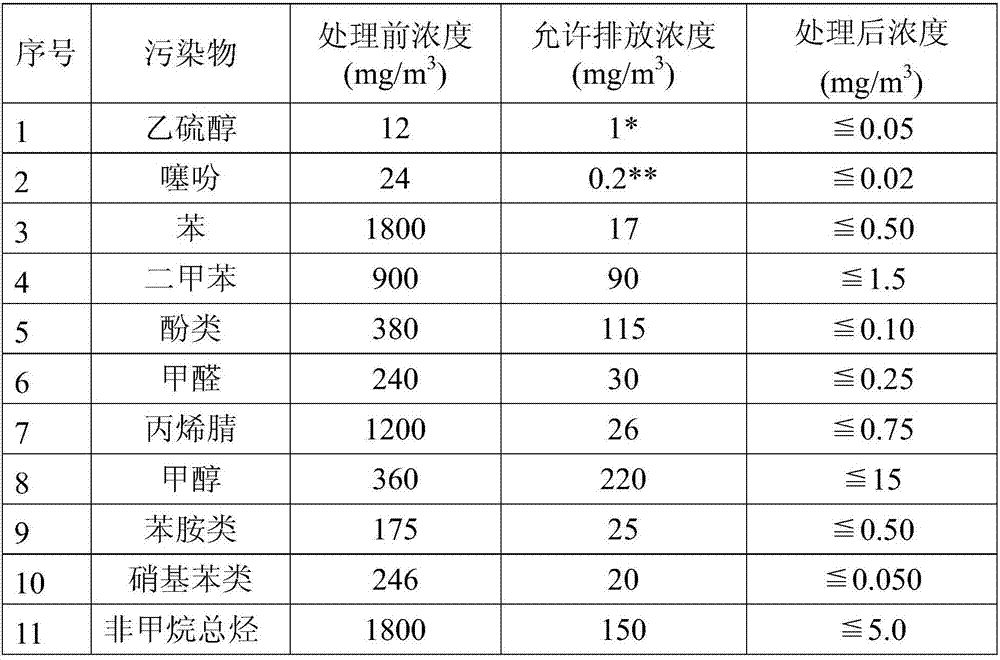

[0056] (2) Put the sulfur-containing VOC gas (the composition is shown in Table 1) and the combustion-supporting gas oxygen into the ceramic tube through the inlet at a linear velocity of 1.2m / min, catalyze combustion at 680°C, and the exhaust gas after combustion flows out from the outlet. Finally absorbed by alkaline substances. The content of each component of VOC remaining in the exhaust gas is lower than the national air pollutant comprehensive discharge standard, as shown in Table 1.

[0057] The harmless treatment result of VOC in...

Embodiment 2

[0061] (1) Copper oxide (CuO) powder with a particle size of 0.1 mm and aluminum oxide (Al 2 o 3 ) according to the mass ratio of 6:4, mix evenly, and fill to such as figure 1 In the shown ceramic tube with an inner diameter of 50 mm and a length of 800 mm, a barrier layer is provided at both ends of the ceramic tube, and the barrier layer is respectively provided with an air outlet and an air inlet;

[0062] (2) Put the sulfur-containing VOC gas (the composition is shown in Table 2) and the combustion-supporting gas oxygen into the ceramic tube through the inlet at a linear velocity of 1.2m / min, and catalyze combustion at 720°C, and the exhaust gas after combustion flows out from the outlet. Finally absorbed by alkaline substances. The content of each component of VOC remaining in the tail gas is lower than the national air pollutant comprehensive discharge standard, as shown in Table 2.

[0063] The harmless treatment result of VOC in table 2 embodiment 2

[0064]

[...

Embodiment 3

[0067] (1) Copper powder with a particle size of 0.1mm and metal titanium dioxide (TiO2) with a particle size of 0.1mm 2 ) according to the mass ratio of 7:3, mix evenly, and fill to such as figure 1 In the shown ceramic tube with an inner diameter of 50mm and a length of 800mm, barrier layers are provided at both ends of the ceramic tube, and the barrier layers at both ends are respectively provided with an air outlet and an air inlet;

[0068] (2) Put sulfur-containing VOC gas (composition shown in Table 1) and combustion-supporting gas oxygen into the ceramic tube through the inlet at a linear velocity of 1.2m / min, catalyze combustion at 720°C, and the exhaust gas after combustion flows out from the outlet. Finally absorbed by alkaline substances. The content of each component of VOC remaining in the tail gas is lower than the national air pollutant comprehensive discharge standard, as shown in Table 3.

[0069] The harmless treatment result of VOC in table 3 embodiment 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com