Production method of vaseline

A production method and Vaseline technology, applied in petroleum wax refining, etc., can solve the problems of expanding the source of Vaseline raw materials, limiting the source of Vaseline raw materials, and fewer varieties of light dewaxing creams, etc., to achieve broadened utilization channels, easy implementation, and unaffected stringiness loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

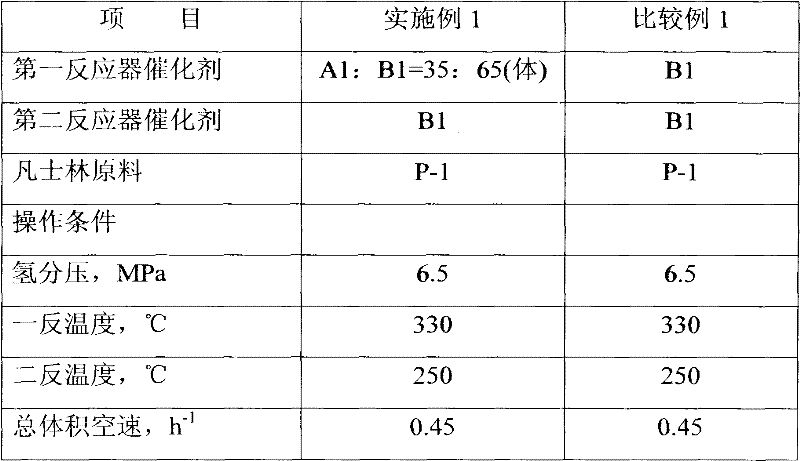

[0028] The modified β molecular sieve in the β molecular sieve-containing catalyst used in the process of the present invention is obtained by a new synthetic modification method, and the main steps of modification include:

[0029] (1) The beta molecular sieve slurry after crystallization is directly subjected to ammonium exchange, filtration, washing, drying and roasting;

[0030] (2) The β molecular sieve after roasting and deammonification carries out acid treatment;

[0031] (3) The acid-treated β molecular sieve is subjected to hydrothermal treatment.

[0032] The above crystallized β molecular sieve is generally synthesized by using organic ammonium (such as tetraethylammonium hydroxide) as a template by hydrothermal crystallization. Its SiO 2 / Al 2 o 3 The weight ratio is generally 25-30, Na 2 The content of O is 3.0wt%-4.0wt%. The crystallized β molecular sieve slurry is directly exchanged with ammonium salt, the concentration of ammonium salt in the slurry is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com