Easily-emulsified compound oil phase for emulsion explosive and preparation method

A technology of emulsified explosive and compound oil phase, which is applied in explosives, non-explosive/non-thermal agent components, offensive equipment, etc., can solve the problems of high speed and high power, and achieve the effect of reducing pipeline pressure and reasonable matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

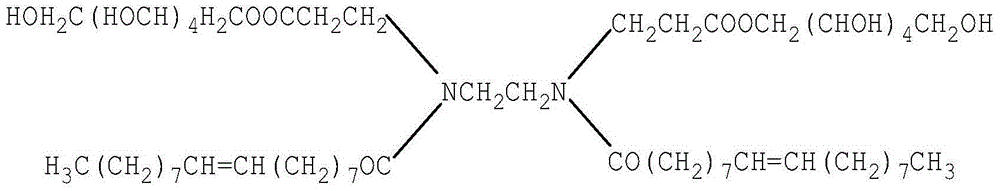

Embodiment 1

[0025] Put paraffin wax 4, 70# microcrystalline wax 8, beeswax 20, 30# engine oil 5, vaseline 20, rosin 8, and octadecyl primary amine 15 in parts by mass into a wax melting tank, heat up to dissolve and melt; heating temperature is 85°C, The temperature was maintained for 60 minutes to obtain a molten mixture. Pump the melted mixture into a blending kettle equipped with a water-in-oil emulsifier to keep warm and stir at a temperature of 85°C for 10 minutes to obtain a blend. The water-in-oil emulsifier is dioleic acid amido diacrylate sorbitan ethylenediamine, and its mass part is 20. The concoction is put into a solidification tank for solidification and molding to obtain an easily emulsifiable composite oil phase for emulsion explosives. The interfacial tension between the composite oil phase and the ammonium nitrate solution is low, and the interfacial tension is 2.05mN / m.

[0026] The above-mentioned easily emulsifiable composite oil phase is used for the production of ...

Embodiment 2

[0028] Example 2: Put paraffin wax 10, 75# microcrystalline wax 2, beeswax 3, 30# engine oil 15, vaseline 10, asphalt 5, put them into the paraffin tank, heat up to melt and melt; heating temperature is 115°C, keep warm for 120 minutes, A molten mixture was obtained. Pump the melted mixture into a blending kettle equipped with a water-in-oil emulsifier to keep warm and stir at a keep temperature of 110°C for 30 minutes to obtain a blend. The water-in-oil emulsifier is dioleic acid amido diacrylate sorbitanyl ethylenediamine, and its mass part is 55%. The concoction is put into a solidification tank for solidification and molding to obtain an easily emulsifiable composite oil phase for emulsion explosives. The interfacial tension between the composite oil phase and the water-soluble ammonium nitrate is low, and the interfacial tension is 1.15mN / m.

[0029] The above-mentioned easily emulsifiable composite oil phase is used for the production of emulsified explosives, the rota...

Embodiment 3

[0031] Embodiment 3: put paraffin wax 7, 85# microcrystalline wax 5, beeswax 10, 50# machine oil 9, vaseline 13, asphalt 10, rosin 4, octadecyl primary amine 8 into the paraffin tank, heat up and melt; The temperature was 105°C and the temperature was maintained for 100 minutes to obtain a molten mixture. Pump the melted mixture into a blending kettle equipped with a water-in-oil emulsifier to keep warm and stir at a temperature of 95°C for 20 minutes to obtain a blend. The water-in-oil emulsifier is dioleic acid amido diacrylate sorbitan ethylenediamine, and its mass part is 34. The concoction is put into a solidification tank for solidification and molding to obtain an easily emulsifiable composite oil phase for emulsion explosives. The interfacial tension between the composite oil phase and the ammonium nitrate solution is low, and the interfacial tension is 0.67mN / m.

[0032] The above-mentioned easily emulsifiable composite oil phase is used for the production of emulsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interfacial tension | aaaaa | aaaaa |

| Interfacial tension | aaaaa | aaaaa |

| Interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com