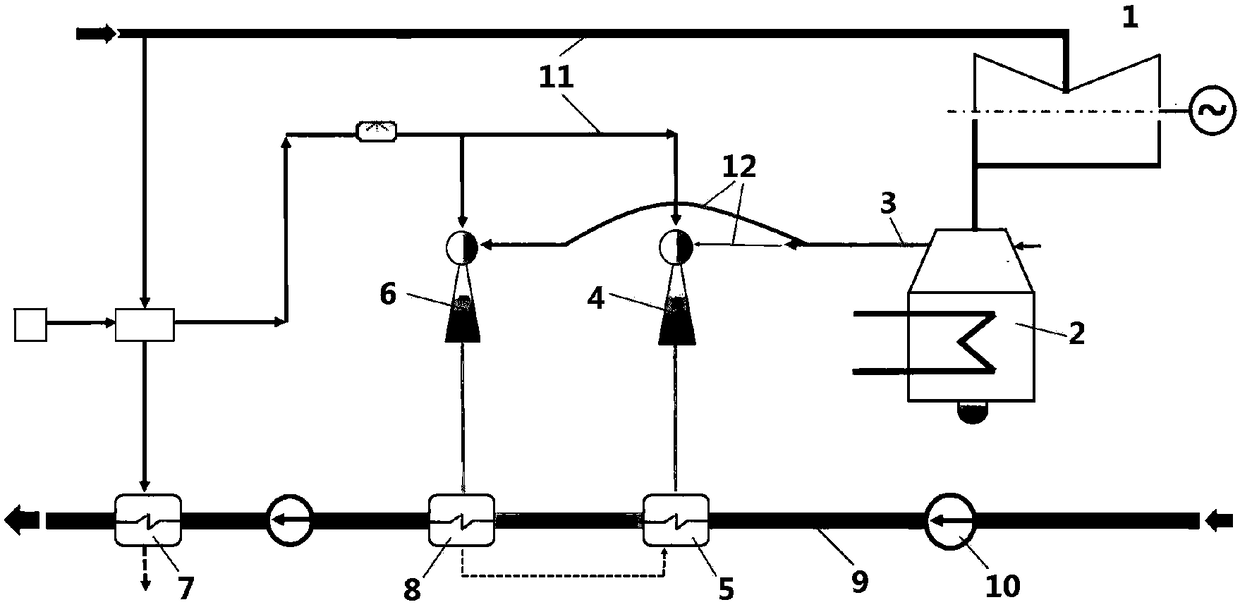

Dead steam waste heat recovery heat supply system for water cooling turboset

A heat supply system and steam turbine unit technology, applied in the field of exhaust steam waste heat recovery heating system, can solve the problems of high return water temperature of the heating network, limited exhaust steam utilization, and limited energy saving benefits, so as to improve the heating capacity, The effect of increasing exhaust steam utilization and reducing cold end loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] A power plant is installed with two 300MW units, and the exhaust steam of one of the steam turbines is recycled.

[0023] The steam turbine unit is water-cooled.

[0024] The exhaust steam recovery and heating system of the water-cooled steam turbine unit in the thermal power plant, including the steam turbine 1 and the corresponding water-cooled condenser 2, the exhaust steam extraction system, and the exhaust steam recovery and utilization heating system of the double-boost ratio steam booster;

[0025] Firstly, the exhaust steam extraction system is used to open holes in the steam turbine condenser, and the exhaust steam entering the condenser of the steam turbine unit is extracted and transported through the exhaust steam extraction pipe. The exhaust steam extraction system includes exhaust steam extraction special parts and exhaust steam extraction pipelines; the exhaust steam extraction special parts are fixedly installed on the throat side of the condenser, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com