Environmental-protection self-snow-melting asphalt pavement admixture and preparation method thereof

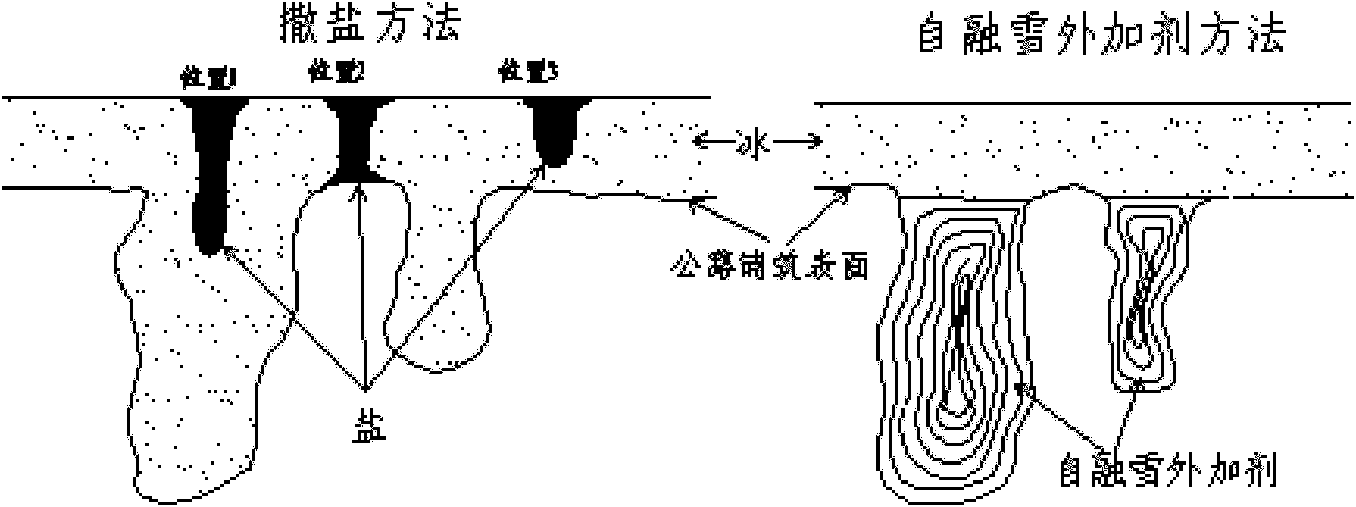

A technology for asphalt pavement and self-melting snow, which is applied in the field of asphalt pavement admixture and its preparation, can solve the problems of polluting the environment and wasting resources, achieve improved compaction and friction coefficient, stable performance, and reduce the incidence of traffic accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Example 1: Production of self-melting snow admixture

[0029] Grind calcium chloride through a pulverizer, sieve and take 850Kg of particles with a particle size below 5mm, and pour them into a mixer. During the mixing process, the glycerin is gradually covered with calcium chloride particles, and a thin oil film is formed on the surface of the calcium chloride particles. At this time, 125Kg of sodium carbonate is put into the mixer, and the sodium carbonate powder will adhere to the surface of the calcium chloride particles. Coated particles are formed on the oil film on the surface of the calcium particles, mixed for 10 minutes, sent to a special dryer via a belt conveyor, and dried at 140°C to 160°C. The dried coated granules are sent to a sieving machine for sieving, and the coated granules with a particle size of 0.1-5mm or less are cooled to room temperature, and finally measured and packaged to obtain an environmentally friendly self-melting snow-melting asphalt ...

example 2

[0030] Example 2: Application of self-melting snow admixture

[0031] The self-melting snow admixture needs to be added to the asphalt mixture, and the use of the admixture is different from that of the general mixture.

[0032] Admixture dosage: The dosage of self-melting snow asphalt pavement admixture is mixed according to 5% of the mass of the mixture.

[0033] Mixing ratio design: The mixing ratio of the asphalt mixture with self-melting snow admixture is the same as that of the normal asphalt mixture, the difference is that the admixture is used to replace part of the mineral materials with the same particle size.

[0034] Porosity: The mixture with self-melting snow-melting admixture has a larger porosity after compaction than the mixture without this material. If the porosity is too large, the service life of the road surface will be greatly reduced, so the porosity must be strictly controlled.

[0035] Mineral powder dosage: During the mixing process of adding self-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com