Guider of automobile shock absorber and manufacturing method thereof

A technology of automobile shock absorbers and guides, which is applied in the field of material processing, can solve problems such as insufficient strength and hardness, low dimensional accuracy, and insufficient strength, and achieve the effects of improving use efficiency and service life, excellent mechanical properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

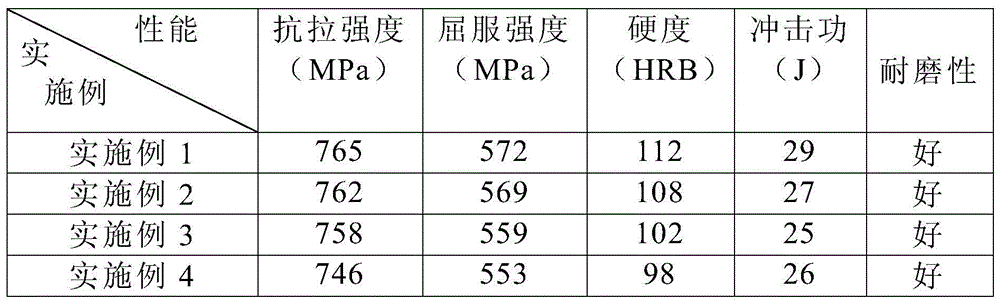

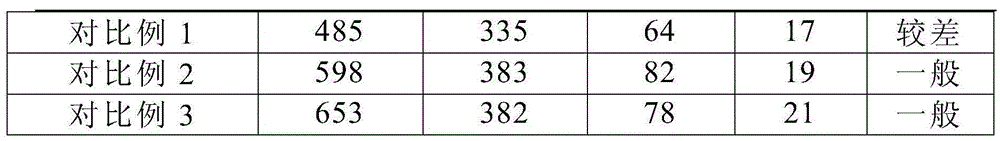

Examples

Embodiment 1

[0027] The automobile shock absorber guide of the present embodiment is made by following method:

[0028] Ingredients: Mix alloy powder, ceramic powder, porogen, and resin binder evenly in a mass ratio of 100:70:0.5:2, wherein the composition and mass percentage of alloy powder are: reduced copper powder: 6%, Graphite powder: 6%, iron phosphide powder: 1%, manganese sulfide: 1.8%, chromium powder: 7%, nickel powder: 2%, the balance is iron powder, and the iron powder includes particles with a mass percentage of 80%. Water atomized iron powder with a diameter of 40-120 μm and reduced iron powder with a particle size of 120-150 μm at a mass percentage of 20%; the particle size of reduced copper powder, graphite powder, iron phosphide powder, manganese sulfide, and chromium powder 30-80 μm; the particle size of the ceramic powder is 30-100nm, including β-SiC with a mass percentage of 55% and HBN with a mass percentage of 45%; the porogen includes porogen I, porogen II and For t...

Embodiment 2

[0033] The automobile shock absorber guide of the present embodiment is made by following method:

[0034] Ingredients: Mix alloy powder, ceramic powder, porogen, and resin binder evenly in a mass ratio of 100:80:0.7:4, wherein the composition and mass percentage of alloy powder are: reduced copper powder: 4%, Graphite powder: 7%, iron phosphide powder: 1.5%, manganese sulfide: 1.5%, chromium powder: 6%, nickel powder: 1.2%, the balance is iron powder, and the iron powder includes 75% by mass of granular Water atomized iron powder with a diameter of 40-120 μm and reduced iron powder with a particle size of 120-150 μm at a mass percentage of 25%; the particle size of reduced copper powder, graphite powder, iron phosphide powder, manganese sulfide, and chromium powder 30-80μm; the particle size of the ceramic powder is 30-100nm, including β-SiC with a mass percentage of 52% and HBN with a mass percentage of 48%; the porogen includes porogen I, porogen II and For the mixture of ...

Embodiment 3

[0039] The automobile shock absorber guide of the present embodiment is made by following method:

[0040] Ingredients: Mix alloy powder, ceramic powder, porogen, and resin binder evenly in a mass ratio of 100:50:1:4, wherein the composition and mass percentage of the alloy powder are: reduced copper powder: 2%, Graphite powder: 8%, iron phosphide powder: 0.3%, manganese sulfide: 3%, chromium powder: 3%, nickel powder: 3%, and the balance is iron powder, and the iron powder includes 90% by mass of particles Water atomized iron powder with a diameter of 40-120 μm and reduced iron powder with a particle size of 120-150 μm at a mass percentage of 10%; the particle size of reduced copper powder, graphite powder, iron phosphide powder, manganese sulfide, and chromium powder 30-80 μm; the particle size of the ceramic powder is 30-100nm, including β-SiC with a mass percentage of 60% and HBN with a mass percentage of 40%; the porogen includes porogen I, porogen II and For the mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com