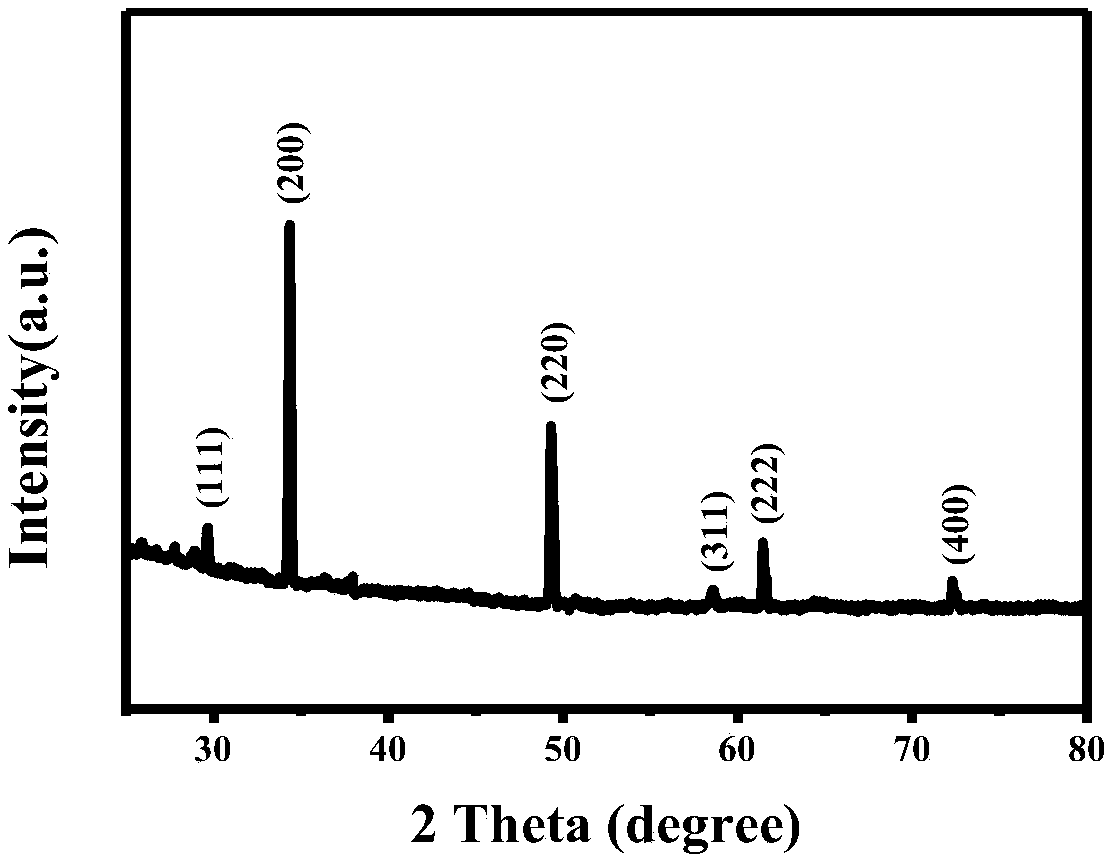

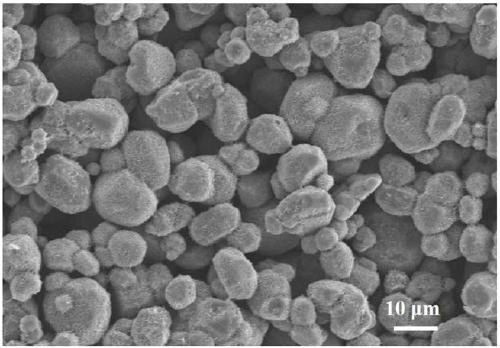

Preparation method of manganese sulfide

A manganese sulfide and sulfur source technology, which is applied in chemical instruments and methods, inorganic chemistry, manganese compounds, etc., can solve the problems of additional surfactants, many steps, and many raw materials, and achieves simple manufacturing process and mild reaction conditions. , the effect of good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 0.245g of manganese acetate tetrahydrate in a mixed solution of 15mL of formamide and 15mL of water, then add 0.150g of thioacetamide, stir evenly, transfer to a stainless steel reaction kettle lined with polytetrafluoroethylene, at 180°C Under reaction for 24 hours. After the reactor was cooled to room temperature, the solid and liquid were separated, the solid was washed with water and ethanol in sequence, and finally the solid was dried at 80° C. to obtain manganese sulfide powder.

[0026] When the manganese sulfide is used as a capacitor electrode material, the specific capacitance is 512F / g.

Embodiment 2

[0028] Get 0.245g of manganese acetate tetrahydrate and dissolve it in a mixed solution of 15mL of triethylamine and 15mL of water, then add 0.232g of allylthiourea, stir evenly, move it into a stainless steel reaction kettle lined with polytetrafluoroethylene, The reaction was carried out at 180° C. for 10 hours. After the reactor was cooled to room temperature, the solid and liquid were separated, the solid was washed with water and ethanol in sequence, and finally the solid was dried at 70° C. to obtain manganese sulfide powder.

[0029] When the manganese sulfide is used as a capacitor electrode material, the specific capacitance is 534F / g.

Embodiment 3

[0031] Get 0.245g of manganese acetate tetrahydrate and dissolve it in a mixed solution of 5mL of triethylamine and 25mL of water, then add 0.182g of thiosemicarbazide, stir evenly, move it into a stainless steel reactor with a polytetrafluoroethylene liner, and heat it at 160 °C for 18 hours. After the reactor was cooled to room temperature, the solid and liquid were separated, the solid was washed with water and ethanol in sequence, and finally the solid was dried at 80° C. to obtain manganese sulfide powder.

[0032] When the manganese sulfide is used as a capacitor electrode material, the specific capacitance is 526F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com