400-MPa-grade fine-grain hot rolled steel bar and manufacturing process thereof

A production process, 400mpa technology, applied in the field of hot-rolled steel bar production, can solve the problems of difficult production of precious alloy elements, and achieve the effects of sustainable development, increased strength, and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

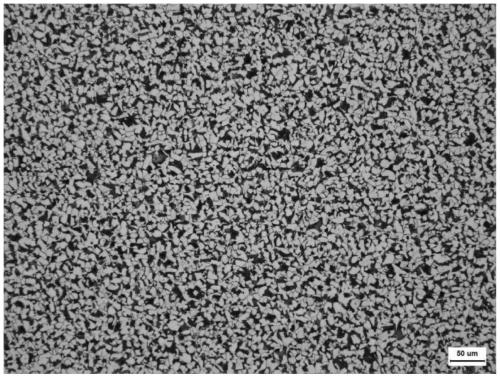

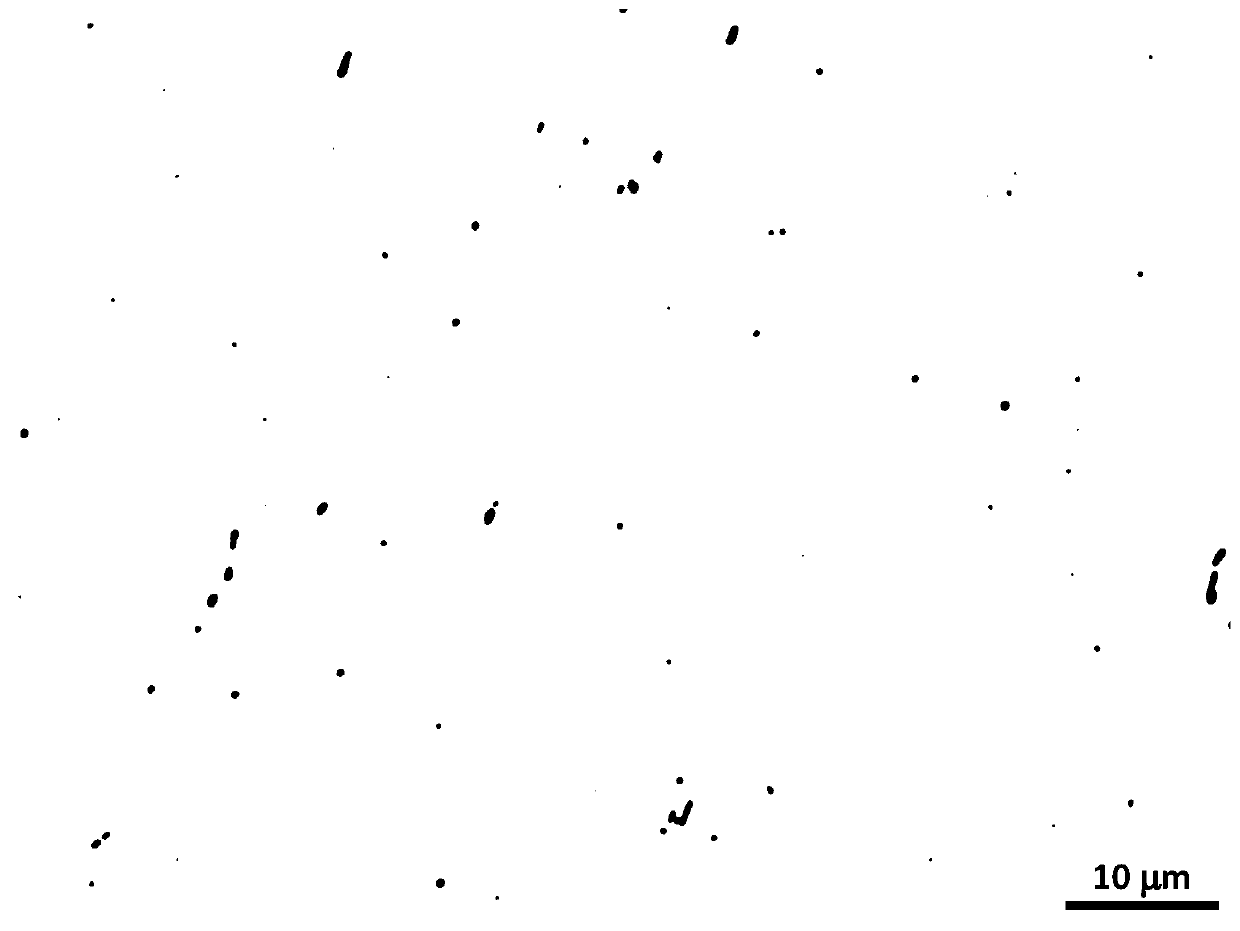

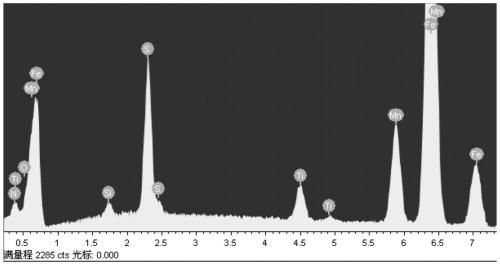

[0060] A 400MPa-grade fine-grained hot-rolled steel bar, the chemical composition and the mass fraction of each chemical composition and the relational expressions satisfied by each element are shown in Table 1. The number of inclusions is shown in Table 2.

[0061] A production process of 400MPa grade fine grain hot-rolled steel bar, comprising the following steps:

[0062] (1) The molten iron is smelted into molten steel in a converter, the tapping temperature is 1665°C, the carbon mass fraction is 0.15%, the oxygen mass fraction is 0.035%, the phosphorus mass fraction is 0.04%, and the sulfur mass fraction is 0.03%. Add silicon and manganese in the process of / 3~3 / 4, according to the chemical composition of 400MPa fine-grained hot-rolled steel bar, adjust the C, Si, Mn element composition of molten steel after tapping;

[0063] (2) Continuous casting is carried out after the molten steel reaches the dissolved oxygen mass fraction of 0.005% and the total oxygen mass fractio...

Embodiment 2

[0068] A 400MPa-grade fine-grained hot-rolled steel bar, the chemical composition and the mass fraction of each chemical composition and the relational expressions satisfied by each element are shown in Table 1. The number of inclusions is shown in Table 2.

[0069] A production process of 400MPa grade fine grain hot-rolled steel bar, comprising the following steps:

[0070] (1) The molten iron and scrap steel are smelted into molten steel in a converter, the tapping temperature is 1670°C, the carbon mass fraction is 0.13%, the oxygen mass fraction is 0.05%, the phosphorus mass fraction is 0.023%, and the sulfur mass fraction is 0.025%, and the tapping temperature is 0.13%. Silicon and manganese are added in the process of 1 / 3 to 3 / 4. According to the chemical composition of 400MPa fine-grained hot-rolled steel bars, the elements of C, Si and Mn in molten steel are adjusted after tapping;

[0071] (2) Continuous casting is carried out after the molten steel reaches the dissol...

Embodiment 3

[0075] A 400MPa-grade fine-grained hot-rolled steel bar, the chemical composition and the mass fraction of each chemical composition and the relational expressions satisfied by each element are shown in Table 1. The number of inclusions is shown in Table 2.

[0076] A production process of 400MPa grade fine grain hot-rolled steel bar, comprising the following steps:

[0077] (1) The molten iron and scrap steel are smelted into molten steel in an electric furnace, the tapping temperature is 1646°C, the carbon mass fraction is 0.12%, the oxygen mass fraction is 0.035%, the phosphorus mass fraction is 0.028%, and the sulfur mass fraction is 0.015%. Silicon and manganese are added in the process of 1 / 3 to 3 / 4. According to the chemical composition of 400MPa fine-grained hot-rolled steel bars, the elements of C, Si and Mn in molten steel are adjusted after tapping;

[0078](2) Continuous casting is carried out after the molten steel reaches a dissolved oxygen mass fraction of 0.00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com