Cobalt nickel metallurgy wastewater sludge recycling method

A treatment method and technology for waste water slag, applied in the field of waste resource utilization, can solve the problems of high cost and long process flow, and achieve the effect of low cost, short process flow and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

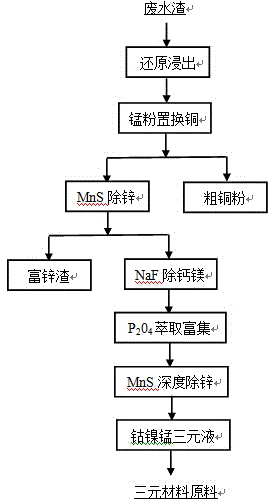

Method used

Image

Examples

Embodiment Construction

[0048] The following table shows the composition of wastewater residue

[0049] Wastewater slag composition %

[0050] co Ni Cu mn Zn Ca Mg Fe Al Cr Na 1.0 3.5 1.8 9.5 4.8 6.9 4.2 0.4 0.3 0.1 20.1 Cd Pb 0.02 0.01

[0051] Slurry waste water according to the solid-liquid ratio of 1:3, add sulfuric acid to maintain the pH of the reaction at 1.5, and add sodium sulfite according to the cobalt-manganese molar ratio of 1:1, stir and react at 70°C for 1.5 hours, and then remove iron from the dissolved solution For metal ions such as aluminum and chromium, add sodium chlorate according to the iron molar ratio of 1:0.3 and sodium tetraphenylborate according to the iron molar ratio of 1:0.02, add liquid caustic soda to adjust the pH of the solution to about 4.0, stir for 1.5 hours and then filter to remove iron The composition of the back liquid is as follows.

[0052] L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com