High performance motorcycle engine powder metallurgy gear cam and manufacturing method thereof

A shift cam, powder metallurgy technology, applied in cams, mechanical equipment, belts/chains/gears, etc., can solve the problem of short service life of motorcycle engine shift cams, failure of drive gear teeth, and failure of drive gear teeth. Wear resistance and other issues, to achieve the effect of saving material costs, high material utilization, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following, the present invention will be further described in conjunction with the embodiments.

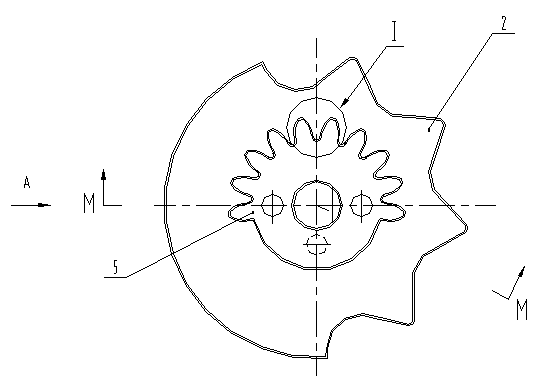

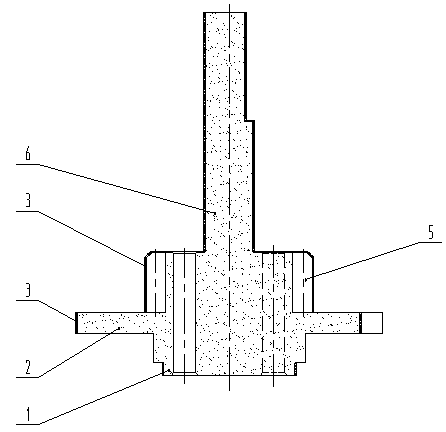

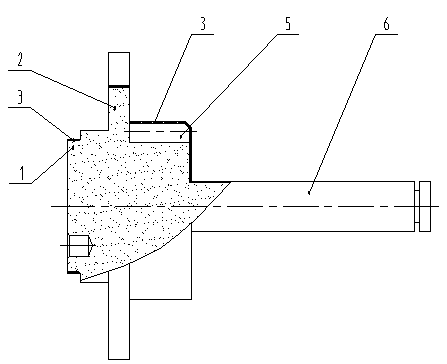

[0033] The high-performance motorcycle engine powder metallurgical shift cam shown in the attached drawing is a stepped shaft part, which includes a supporting journal 1, a shift cam 2, a drive gear mounting journal 6, and a drive gear arranged on the same axis. 5. The drive gear 5 is located between the shift cam 2, the drive gear mounting journal 6, and is an integral structure with the supporting journal 1, the shift cam 2, and the drive gear mounting journal 6, and the main body is powder metallurgy; The rounded transition between the tooth roots of the adjacent driving gear 5; the outer wall of the supporting journal 1, the cam outer wall of the shift cam 2, the outer wall of the drive gear mounting journal 6, and the outer wall of the drive gear 5 are provided with a wear-resistant composite layer 3 , The preferred solution: the wear-resistant composite layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com